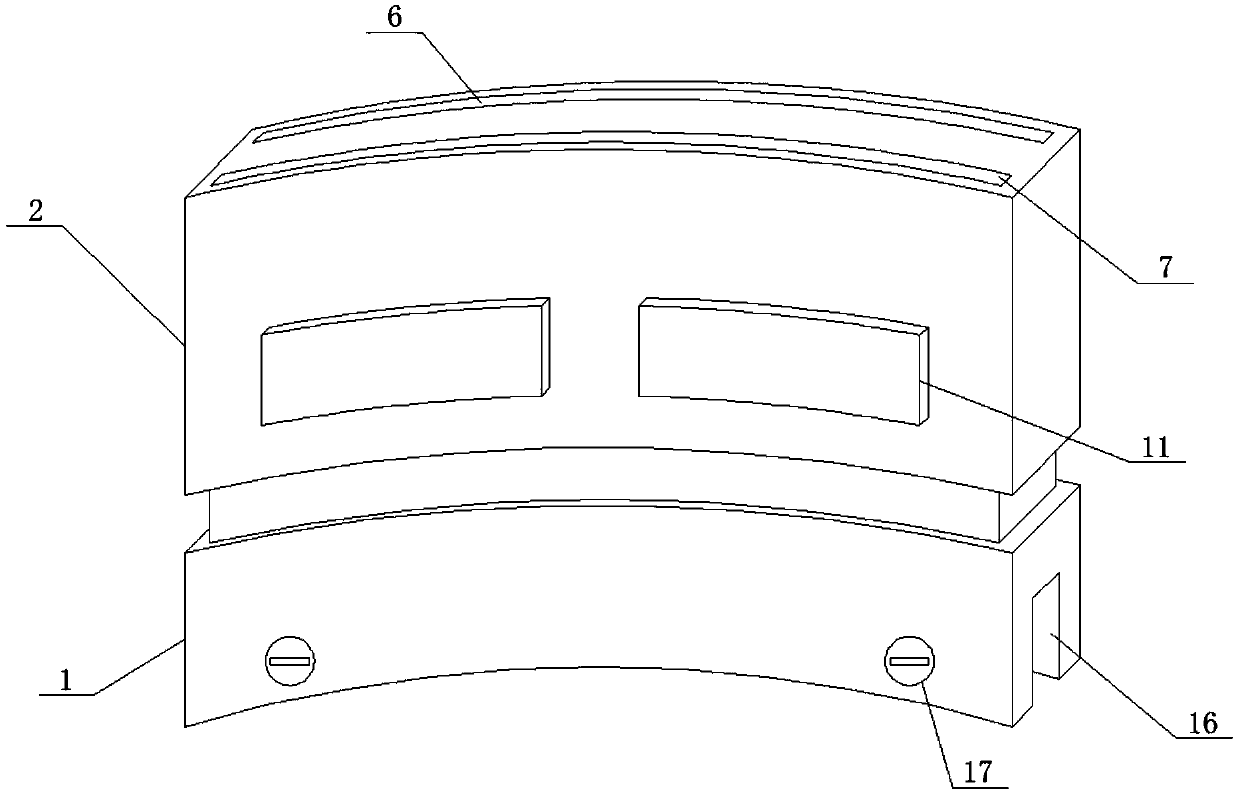

Combined type diamond cutter head

A diamond cutter head, combined technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of rough incision, easy blockage, not smooth enough, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

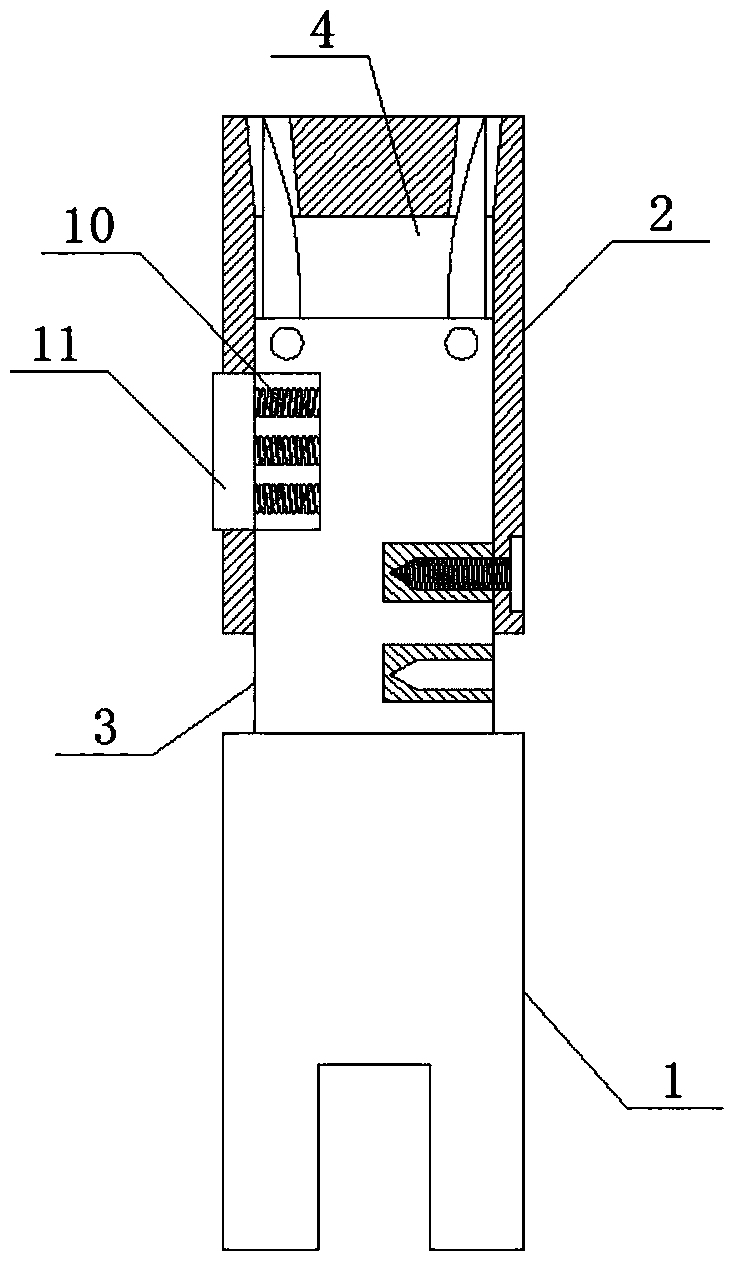

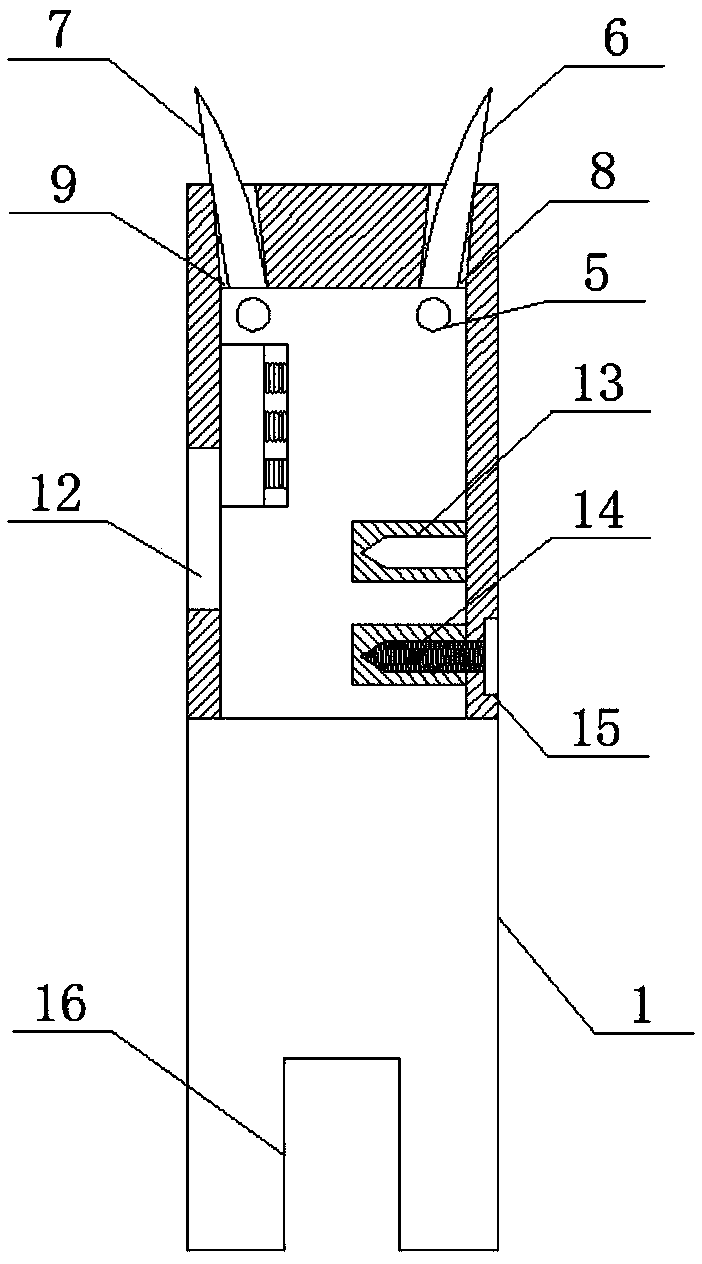

[0024] As a preferred embodiment of the present invention, the volume of the cutter head block 1 is equal to the volume of the placement cavity 4 .

[0025] As a preferred embodiment of the present invention, the first blade 6 and the second blade 7 have the same size.

[0026] As a preferred embodiment of the present invention, the elastic piece 11 corresponds to the opening 12, and the number of the elastic piece 11 and the opening 12 are two.

[0027] As a preferred embodiment of the present invention, the through hole 15 corresponds to the first screw hole 13 and the second screw hole 14 .

[0028] As a preferred embodiment of the present invention, the distance between the first screw hole 13 and the second screw hole 14 is equal to the distance between the top of the protruding block 3 and the top of the placement cavity 4 .

[0029] As a preferred embodiment of the present invention, the cutter head block 1 is provided with a base locking groove 16 , and a screw hole 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap