Labeling robot equipment suitable for high-temperature environment, system and method

A high-temperature environment, robot technology, applied in the field of robots, can solve the problems of harsh working environment in steel production, potential safety hazards, affecting physical health, etc., to shorten logistics and inventory costs, improve product quality traceability, and reduce manual records.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

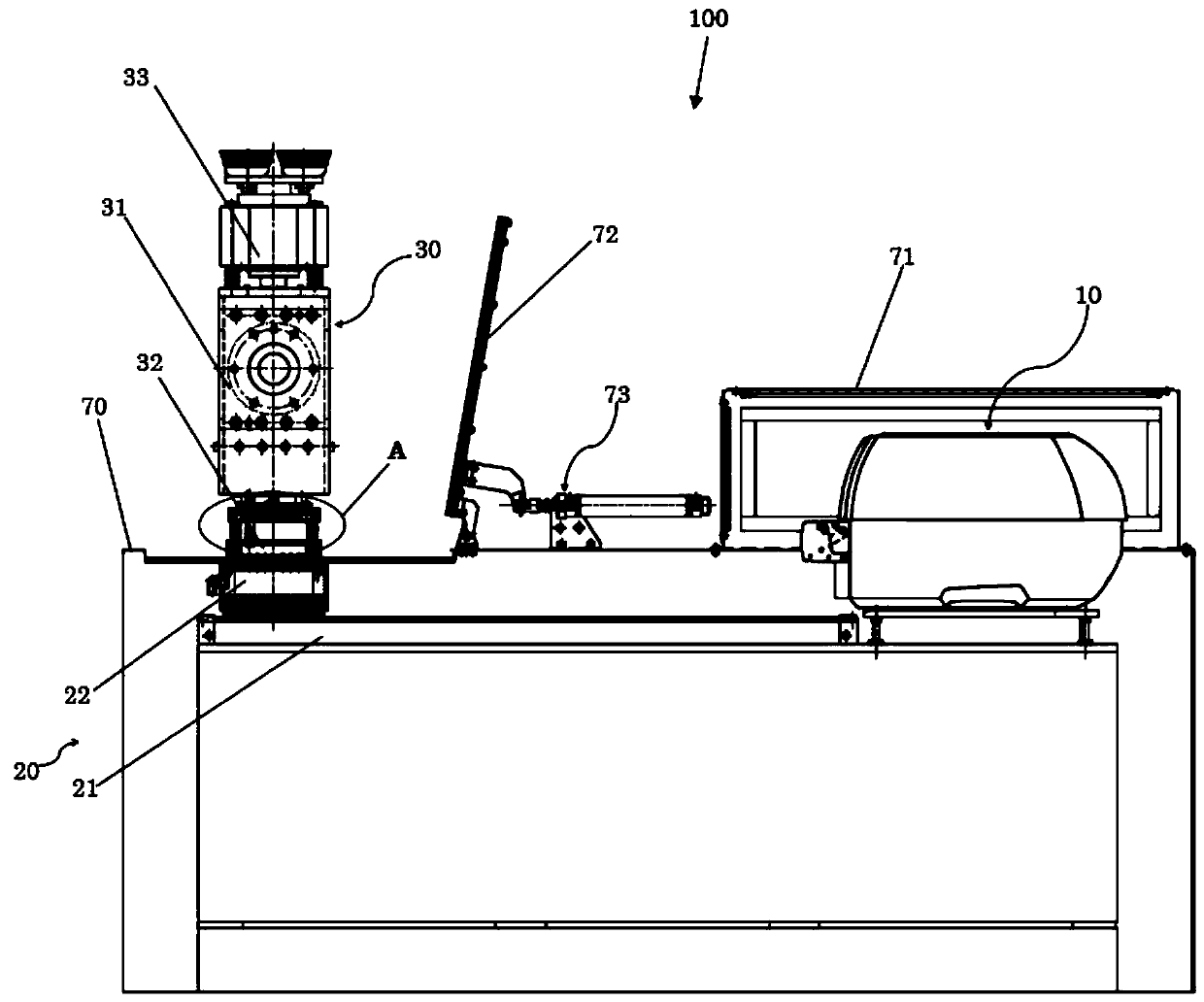

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments describe a labeling robot equipment, a labeling robot system and a labeling robot suitable for high temperature environments of the present invention in conjunction with the accompanying drawings The method is described in detail.

[0027] In this embodiment, a labeling robot equipment 100 suitable for a high temperature environment is provided, which is used for labeling a steel billet of a high temperature product, and the temperature of the steel billet is as high as 450-800°.

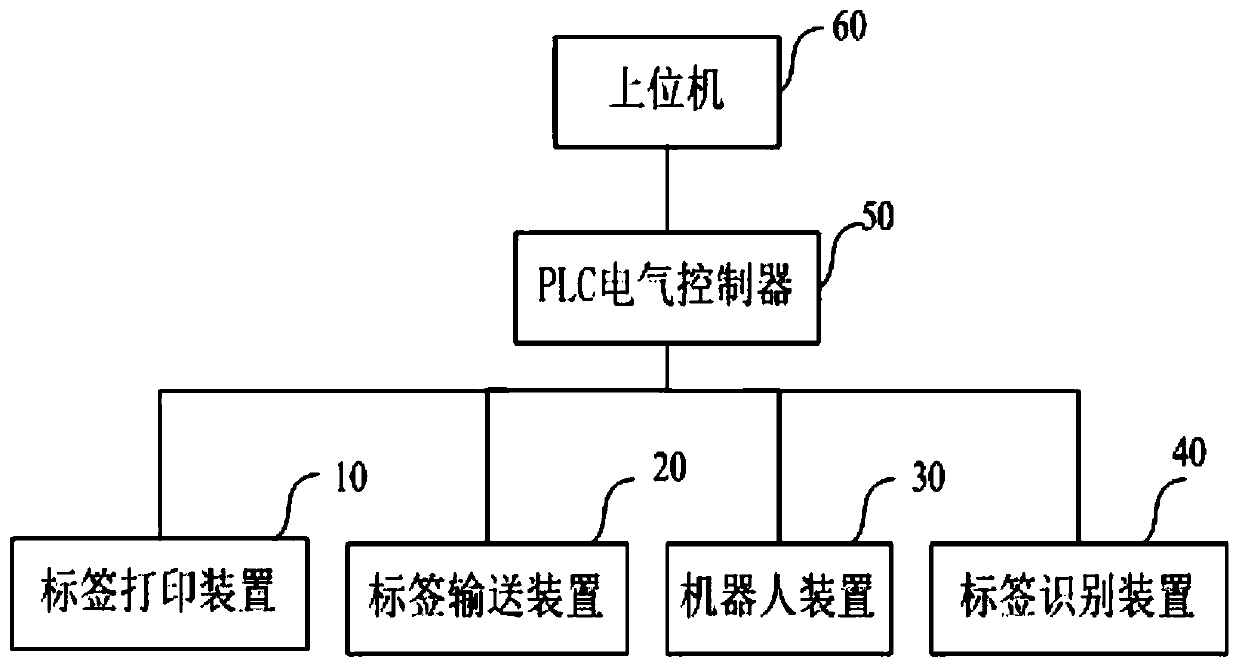

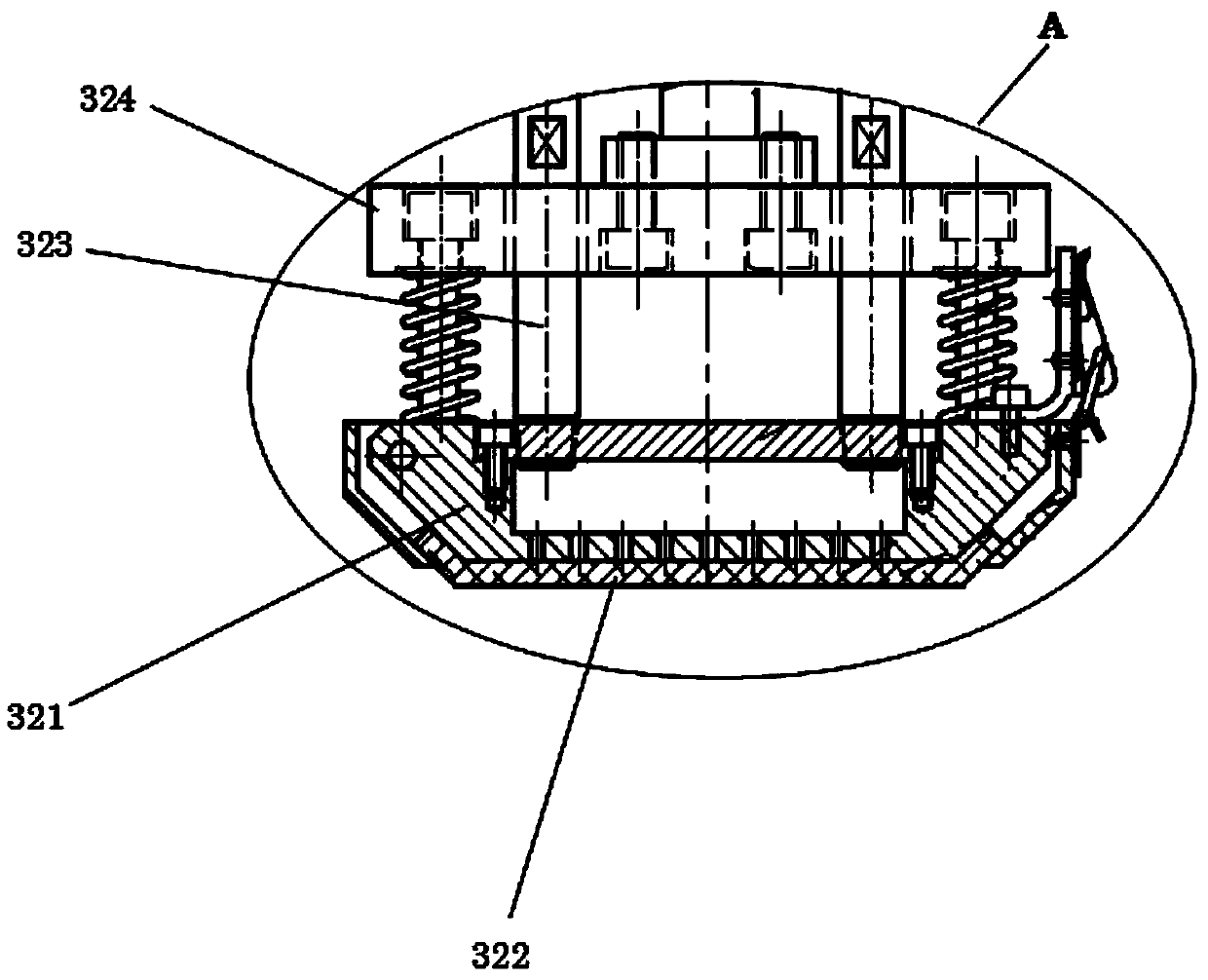

[0028] like Figure 1~2 As shown, the labeling robot equipment 100 suitable for high-temperature environments in this embodiment includes a label printing device 10, a label conveying device 20, a robot device 30, and a label recognition device 40 ( figure 1 Not shown in), PLC electrical controller 50 ( figure 1 not shown in the figure), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com