A kind of transparent permanent antistatic PMMA material and its preparation method and application

An antistatic agent and preparation process technology, which is applied in the field of transparent permanent antistatic PMMA material and its preparation, can solve the problems of large influence on PMMA mechanical properties, unsuitable scale application, and difficult introduction, and achieve excellent antistatic performance and low cost. Low, excellent effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

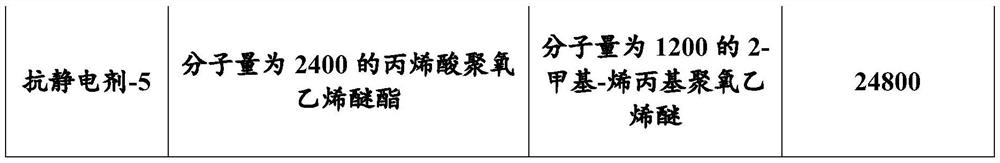

[0042] The antistatic agent used in Examples 1-8 was prepared by referring to the synthesis method in Patent No. 201610168598.4. The synthesis method comprises the steps of: adding deionized water, acrylate monomer A and polyether monomer B to a glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a reflux condenser, and then heating it to 65°C, Subsequently, a 40% mixed aqueous solution of acrylic acid, sodium methallylsulfonate, and sodium hypophosphite, and a 37.2% aqueous solution of ammonium persulfate were added dropwise over 3 hours and 3.5 hours, respectively. Then keep the temperature at 65°C until the end of the polymerization reaction, then cool the resulting reaction mixture to no more than 50°C, then neutralize it with 30% aqueous sodium hydroxide solution to adjust the pH to 5-7, and obtain the aqueous copolymer solution by spraying After drying, an antistatic agent product is obtained. The product name of antistatic agent, acrylate monome...

Embodiment 1

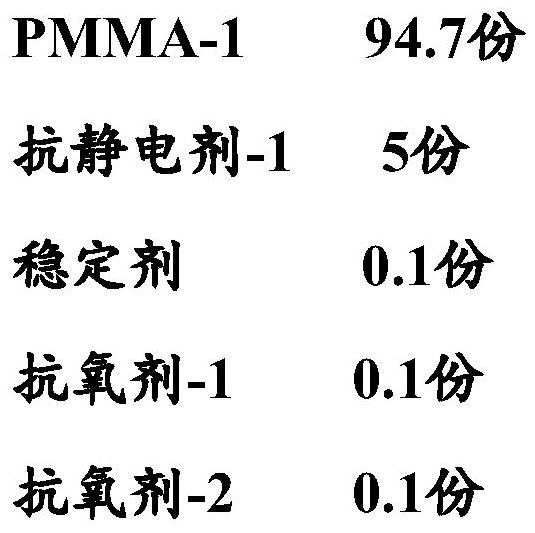

[0047] Add PMMA, antistatic agent, stabilizer and antioxidant to a high-speed mixer and mix thoroughly, and then transfer it to a twin-screw extruder with a length-to-diameter ratio of 48 and a total of 12 barrels for melt extrusion and granulation , the temperature of the second barrel is 185°C, the temperature of the third barrel is 230°C, the temperature of the fourth barrel is 220°C, the temperature of the fifth barrel is 220°C, and the temperature of the sixth barrel is 210°C , the seventh barrel temperature is 210°C, the eighth barrel temperature is 205°C, the ninth barrel temperature is 205°C, the tenth barrel temperature is 205°C, and the eleventh barrel temperature is 205°C ℃, the barrel temperature in the twelfth section is 205 ℃, the head temperature is 205 ℃, the feeding frequency is 40 Hz, the host speed is 400 rpm, and the vacuum is pumped to a vacuum degree of -0.05MPa. A transparent permanent antistatic PMMA material is obtained.

[0048] The parts by weight o...

Embodiment 2

[0051] PMMA, antistatic agent and antioxidant are added into a high-speed mixer and mixed thoroughly, and then transferred to a twin-screw extruder with a length-to-diameter ratio of 48 and a total of 12 barrels for melt extrusion and granulation. The temperature of the first barrel is 180°C, the temperature of the third barrel is 230°C, the temperature of the fourth barrel is 220°C, the temperature of the fifth barrel is 220°C, the temperature of the sixth barrel is 210°C, and the temperature of the seventh barrel is 210°C. The temperature of the barrel section is 210°C, the barrel temperature of the eighth section is 205°C, the barrel temperature of the ninth section is 205°C, the barrel temperature of the tenth section is 205°C, and the barrel temperature of the eleventh section is 205°C. The temperature of the twelve-section barrel is 205°C, the temperature of the machine head is 205°C, the feeding frequency is 40 Hz, the speed of the main engine is 400 rpm, and the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com