A uv LED low energy curing formaldehyde removal solid wood composite home furnishing

A composite home furnishing and low-energy technology, which can be used in biocide-containing paints, coatings, antifouling/underwater coatings, etc. It can solve the unconcerned problems of bacterial growth, unsatisfactory bond strength, and poor aldehyde removal performance. Stability and other issues, to achieve the effects of controlling the occurrence and spread of diseases, good aldehyde removal effect, and strong environmental performance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

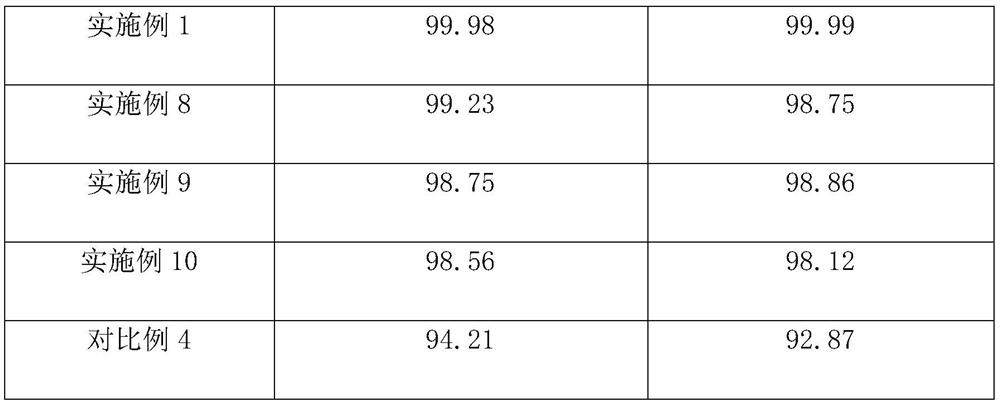

Examples

Embodiment 1

[0040] Embodiment 1 A UV LED low-energy curing aldehyde-removing solid wood composite home board, including a substrate board, one side of the substrate board is coated with a waterproof layer, which is the bottom surface; the other side of the substrate board Adhesive sealing layer, filling layer, primer layer and functional layer are coated sequentially from bottom to top, and this side is the front side;

[0041] Described adhesion sealing layer is adhesion putty;

[0042] The filling material of the filling layer is activated carbon;

[0043] Described primer layer is environment-friendly UV paint,

[0044] The functional layer is an aldehyde-removing antibacterial UV-curable coating;

[0045] The waterproof layer is a universal waterproof paint, and the universal waterproof paint is a product of the model K11 produced by Guangzhou Deyi Waterproof Material Co., Ltd.; the film thickness of the waterproof layer is 3mm;

[0046] The attached sealing layer is an attached pu...

Embodiment 2

[0060] The difference with Example 1 is: the described aldehyde-removing antibacterial UV-curable coating comprises by weight: 55 parts of polyurethane acrylate, 50 parts of 1,6-hexanediol diacrylate, trimethylolpropane trimethylolpropane 15 parts of acrylate, 34 parts of 3-phenoxyethyl acrylate, 7 parts of superfine alumina powder, 13 parts of matte powder, 7 parts of wax powder, 12 parts of nano-silicon chip, 5 parts of chitin, ammonium dihydrogen phosphate 25 parts and 38 parts water.

Embodiment 3

[0062] The difference from Example 1 is that the aldehyde-removing antibacterial UV-curable coating includes by weight: 58 parts of polyurethane acrylate, 60 parts of 1,6-hexanediol diacrylate, trimethylolpropane trimethylolpropane 18 parts of acrylate, 37 parts of 3-phenoxyethyl acrylate, 8 parts of superfine alumina powder, 16 parts of matte powder, 9 parts of wax powder, 14 parts of nano-silicon chip, 8 parts of chitin, ammonium dihydrogen phosphate 28 parts and 42 parts water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com