Hydrolyzed gelatin and diatomite covalently bonded aldehyde-removing composite material and preparation method thereof

A technology of hydrolyzing gelatin and covalent bonding, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of easy loss of active components and achieve long-lasting and good aldehyde removal effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

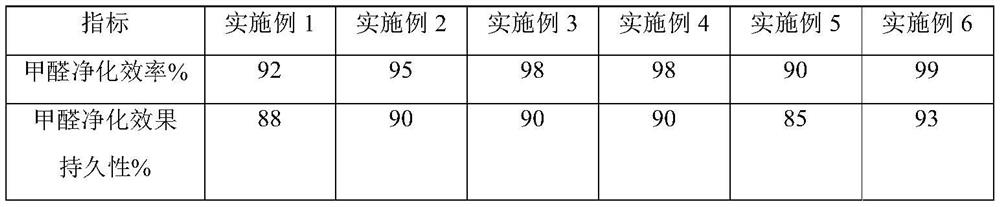

Examples

Embodiment 1

[0014] The aldehyde-removing composite material covalently bonded with hydrolyzed gelatin and diatomite consists of the following components in parts by weight:

[0015] (A) 100 parts of diatomaceous earth, and

[0016] (B) 10 parts of hydrolyzed gelatin with a molecular weight of 2000.

[0017] The preparation method of the above-mentioned long-acting aldehyde-removing composite material: add 10 parts of hydrolyzed gelatin to 100 parts of water and stir at 20°C for 0.5h to dissolve, then add 100 parts of diatomaceous earth and continue stirring for 0.5h, and dry at 70°C; then dry The final diatomite containing hydrolyzed gelatin is dispersed in 200 parts of N,N-dimethylformamide, and 1 part of catalyst 4-dimethylaminopyridine and 10 parts of dehydrating agent 1-(3-dimethylaminopropyl )-3-Ethylcarbodiimide hydrochloride, reacted at 90°C for 10h. Cool down, filter, wash with ethanol and dry at 70°C, and grind to obtain a aldehyde-removing composite material in which hydrolyze...

Embodiment 2

[0019] The aldehyde-removing composite material covalently bonded with hydrolyzed gelatin and diatomite consists of the following components in parts by weight:

[0020] (A) 100 parts of diatomaceous earth, and

[0021] (B) 20 parts of hydrolyzed gelatin with a molecular weight of 3000.

[0022] The preparation method of the above-mentioned long-acting aldehyde-removing composite material: add 20 parts of hydrolyzed gelatin to 100 parts of water and stir at 30°C for 1 hour to dissolve, then add 100 parts of diatomaceous earth and continue stirring for 0.5 hours, and dry at 80°C; Diatomaceous earth containing hydrolyzed gelatin is dispersed in 200 parts of N,N-dimethylformamide, adding 2 parts of catalyst 4-dimethylaminopyridine and 20 parts of dehydrating agent 1-(3-dimethylaminopropyl) -3-Ethylcarbodiimide hydrochloride, react at 100°C for 20h. Cool down, filter, wash with ethanol and dry at 80°C, and grind to obtain a aldehyde-removing composite material chemically covalen...

Embodiment 3

[0024] The aldehyde-removing composite material covalently bonded with hydrolyzed gelatin and diatomite consists of the following components in parts by weight:

[0025] (A) 100 parts of diatomaceous earth, and

[0026] (B) 30 parts of hydrolyzed gelatin with a molecular weight of 4000.

[0027] The preparation method of the above-mentioned long-acting aldehyde-removing composite material: add hydrolyzed gelatin to 100 parts of water and stir at 40°C for 2 hours to dissolve it, then add 100 parts of diatomaceous earth to continue stirring for 1 hour, and dry at 80°C; then the dried hydrolyzed gelatin Diatomaceous earth of glue is dispersed in 200 parts of N,N-dimethylformamide, 5 parts of catalyst 4-dimethylaminopyridine and 30 parts of dehydrating agent 1-(3-dimethylaminopropyl)-3-ethane Carbodiimide hydrochloride, reacted at 110°C for 30h. Cool down, filter, wash with ethanol and dry at 90°C, and grind to obtain a aldehyde-removing composite material in which hydrolyzed ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com