A kind of 550mpa grade cold-rolled corrosion-resistant dual-phase steel and its manufacturing method

A dual-phase steel and corrosion-resistant technology, which is applied in the field of high-strength cold-rolled dual-phase steel production, can solve the problems that the strength and corrosion resistance cannot meet the use requirements, the corrosion resistance cannot meet the requirements, and it is not suitable for mass production. , to achieve excellent medium corrosion resistance, good atmospheric corrosion resistance, and energy saving effects

Active Publication Date: 2020-03-31

ANGANG STEEL CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the strength of this invention reaches more than 700MPa, the corrosion resistance cannot meet the requirements

[0006] In the patents disclosed above, either the strength and corrosion resistance cannot meet the requirements for use, or they are not suitable for mass production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0036] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

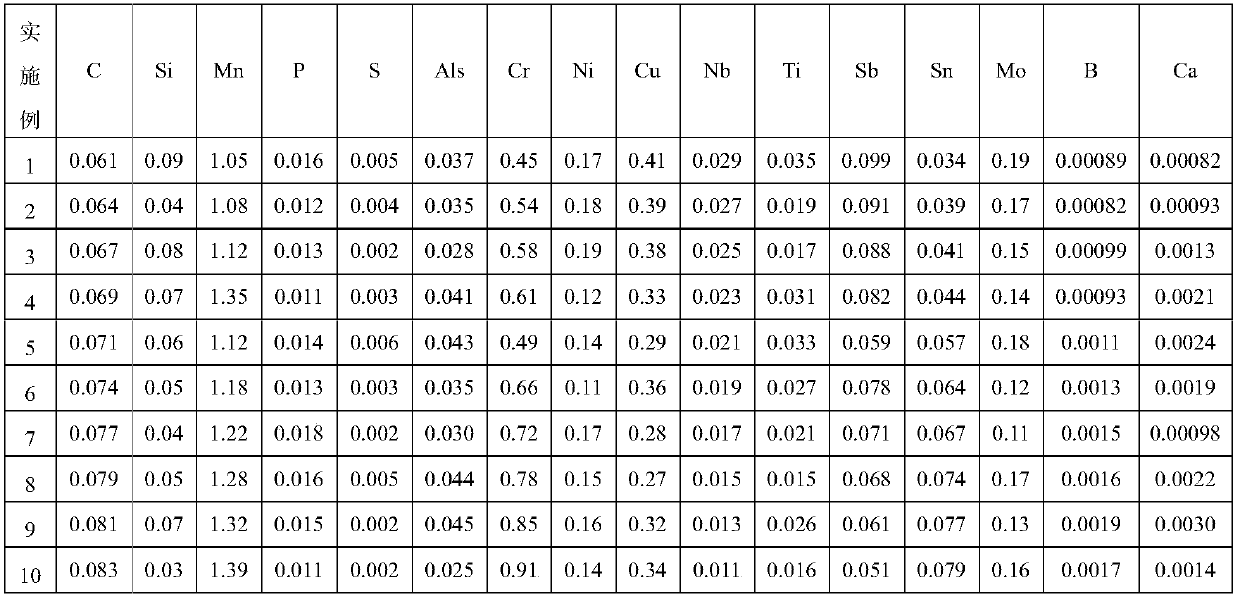

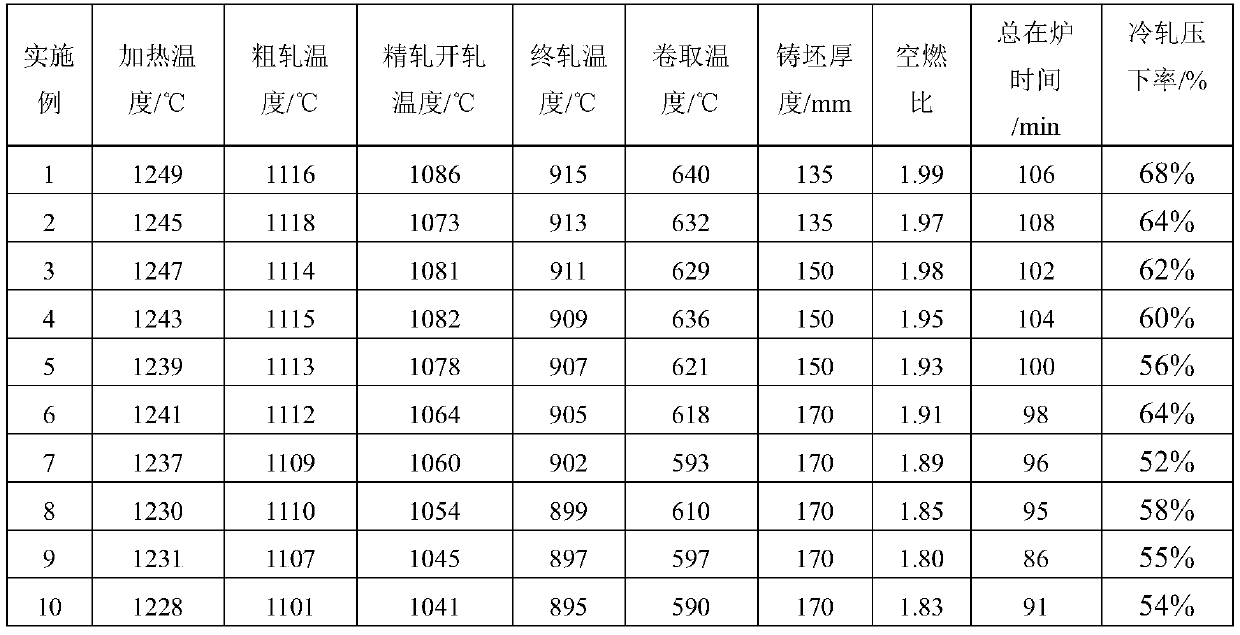

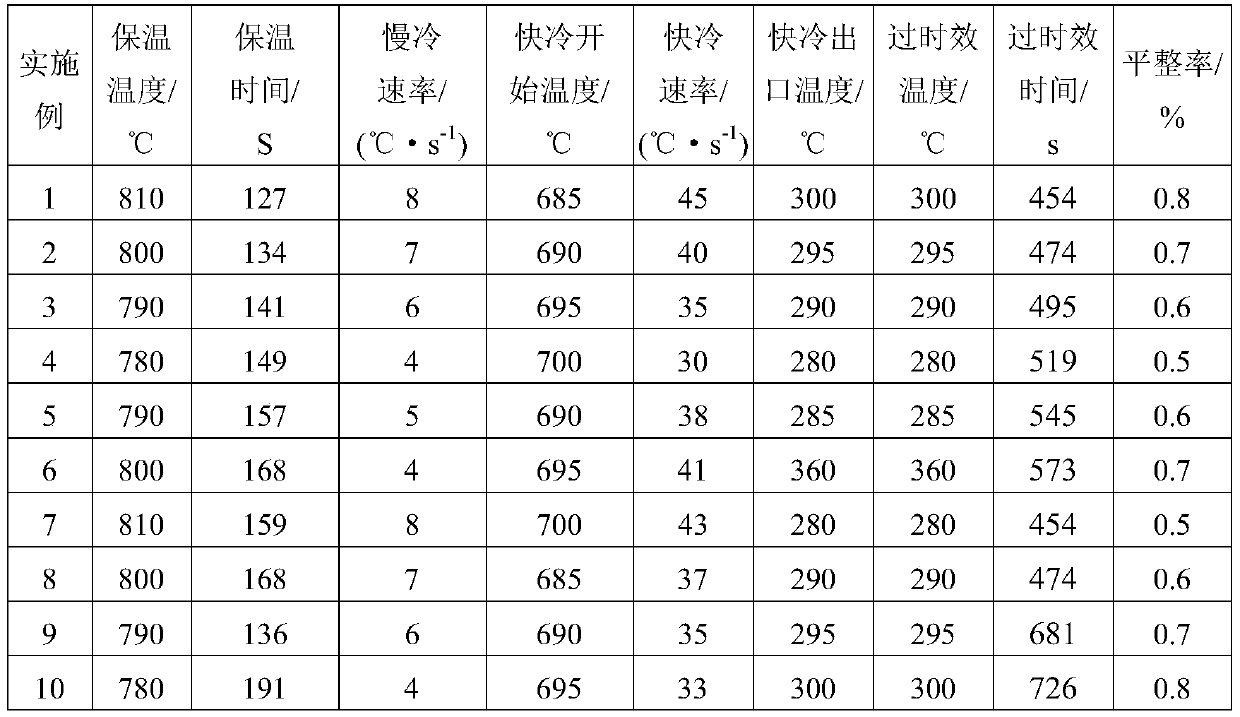

The invention discloses a 550MPa grade cold-rolled corrosion-resistant dual-phase steel and a manufacturing method thereof. The steel comprises 0.061%-0.083% of C, less than 0.10% of Si, 1.05%-1.39% of Mn, less than or equal to 0.018% of P, less than or equal to 0.006% of S, 0.015%-0.045% of Als, 0.45%-0.91% of Cr, 0.11%-0.19% of Ni, 0.27%-0.41% of Cu, 0.011%-0.029% of Nb, 0.015%-0.035% of Ti, 0.046%-0.099% of Sb, 0.034%-0.079% of Sn, 0.11%-0.19% of Mo, 0.0008%-0.0019% of B, 0.0008%-0.0030% of Ca and the balance iron and unavoidable impurities. A 135-170mm casting blank is heated to 1228-1249DEG C, the total in-furnace time is not longer than 110 min, the rough rolling temperature is higher than 1100 DEG C, the finishing rolling finishing temperature is 895 to 915 DEG C, annealing is conducted at 790 to 820 DEG C, and steel sheets is excellent in corrosion resistance.

Description

technical field [0001] The invention belongs to the technical field of high-strength cold-rolled dual-phase steel production, and in particular relates to a cold-rolled dual-phase steel with corrosion resistance used for railway vehicles, containers and the like and a manufacturing method thereof. Background technique [0002] For transportation structures, there is an urgent need for lightweight containers to increase the weight of goods that can be transported at a time, and materials such as stainless steel or aluminum alloys have been used to manufacture lightweight containers or railway vehicles and extend their life. However, due to their high production costs, their applications are limited. However, the corrosion resistance of existing cold-rolled steel sheets cannot fully meet the requirements for use. In order to meet the needs of steel plate thinning, the development of ultra-high-strength cold-rolled corrosion-resistant steel plates with a yield strength of 550M...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/42C22C38/48C22C38/50C22C38/60C22C38/44C22C38/54C21D8/02

CPCC21D8/0226C21D8/0236C21D8/0247C21D2211/005C21D2211/008C22C38/008C22C38/02C22C38/04C22C38/06C22C38/42C22C38/44C22C38/48C22C38/50C22C38/54C22C38/60

Inventor 刘志伟孙傲张瑞琦郭晓宏杨玉金星景鹤孙荣生王静

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com