Steel structure civil defense door and manufacturing process thereof

A technology for civil air defense doors and steel structures, which is applied in manufacturing tools, building structures, door leaves, etc., can solve the problems of difficult disassembly, heavy structure, resource occupation, etc., to improve the sound insulation effect, easy to move and transport, easy to install and disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

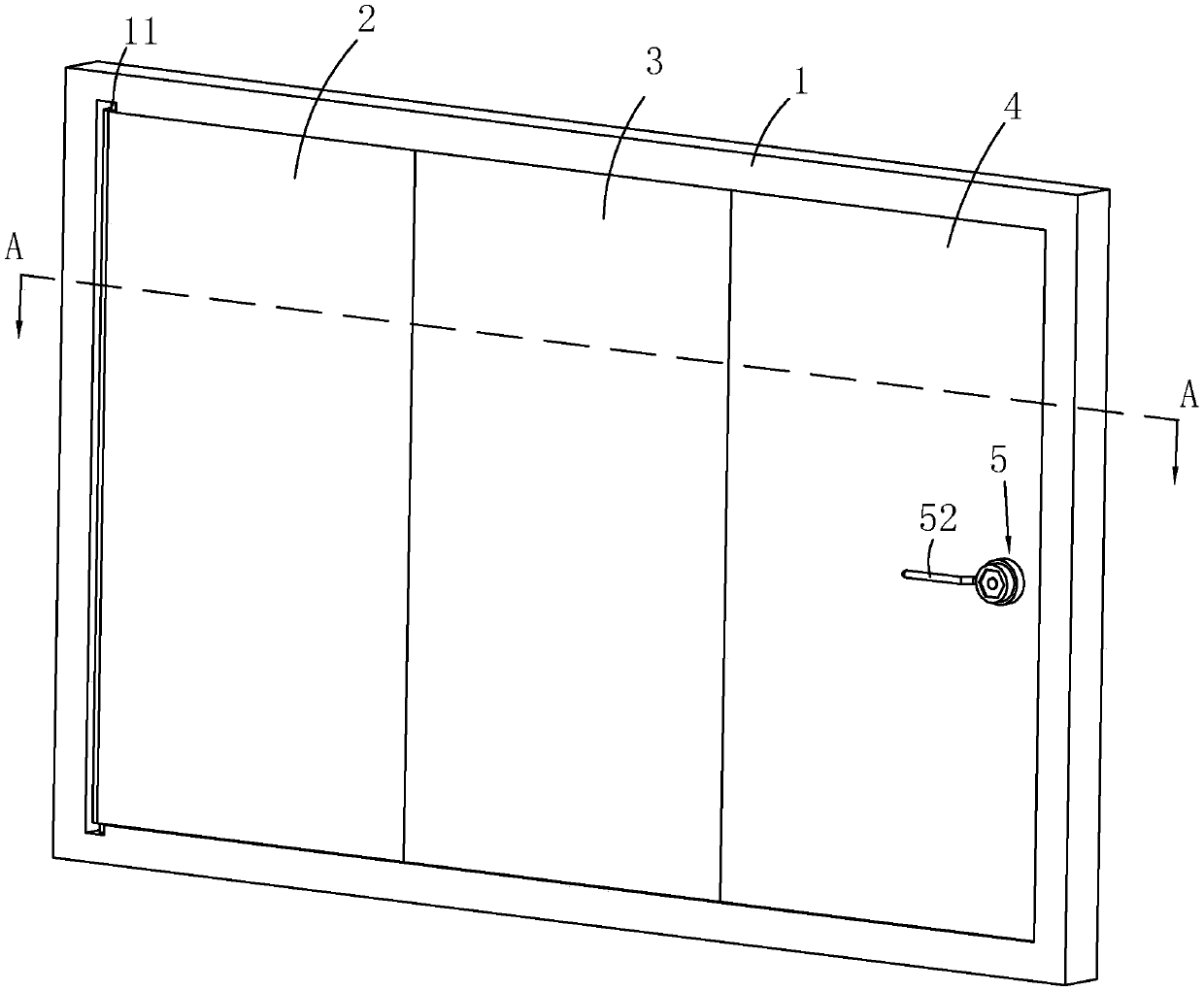

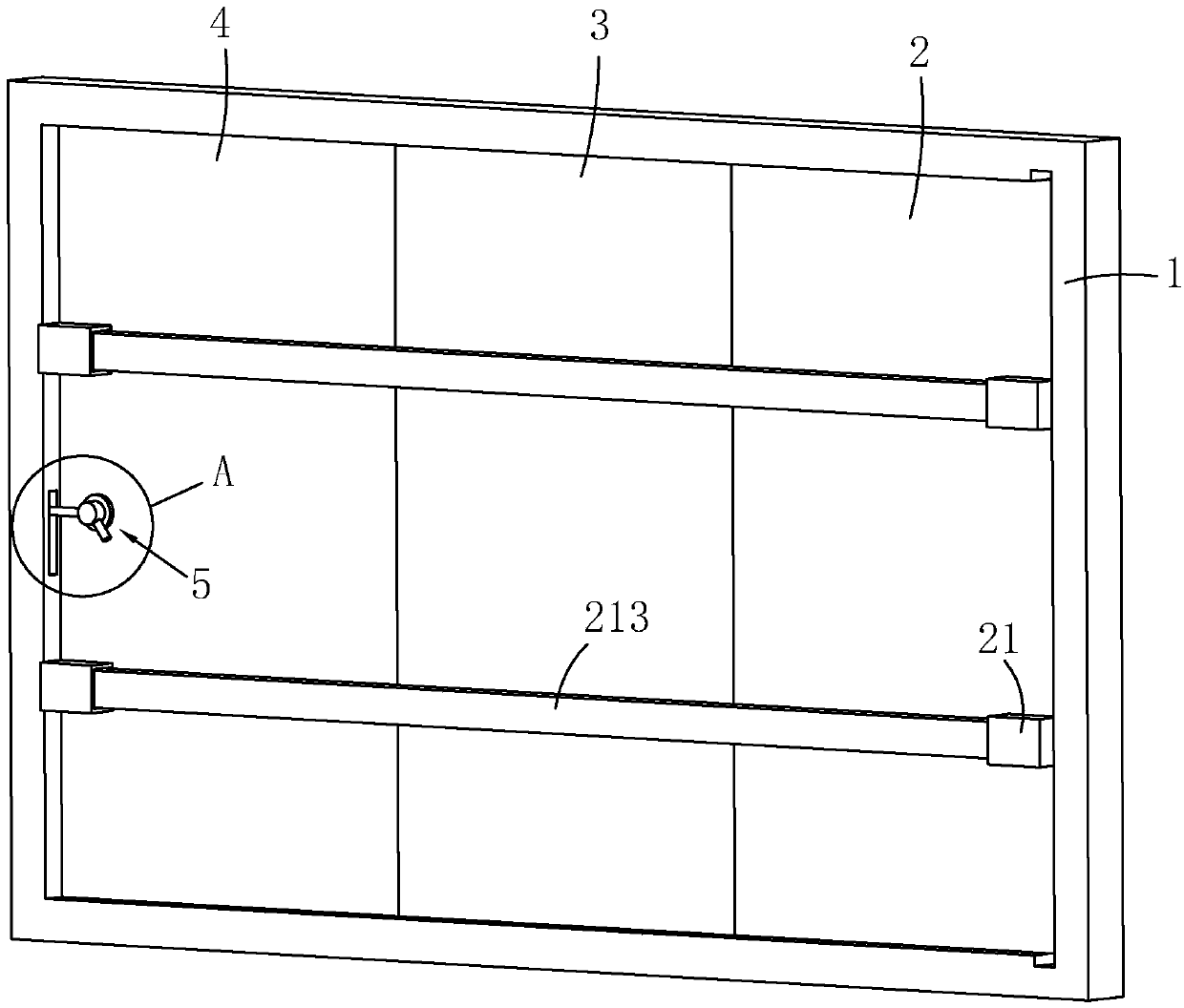

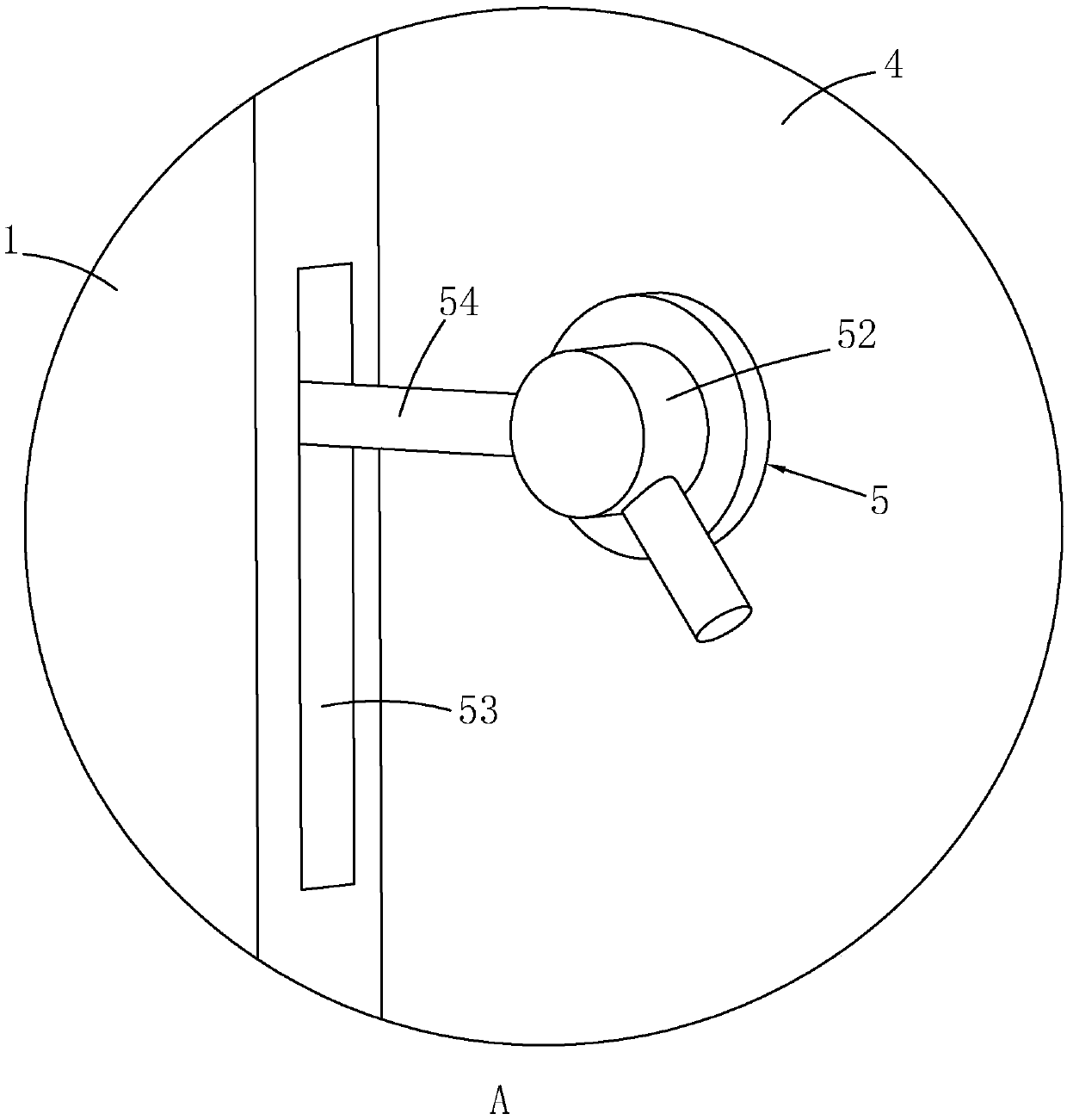

[0044] refer to figure 1 with figure 2, is a steel structure air defense door disclosed by the present invention, comprising a door frame 1 and a door body arranged in the door frame 1, wherein the door frame 1 is pre-buried in the wall, and the door body includes a first door body 2, a second door body 3 and the third door body 4; the first door body 2 and the door frame 1 are hinged through the rotating shaft 11, the second door body 3 is arranged between the first door body 2 and the second door body 3, and the third door body 4 is provided with Open and close structure 5, combine image 3 As shown, the opening and closing structure 5 includes an opening and closing shaft 51 which is horizontally rotated and arranged on the third door body 4. One end of the opening and closing shaft 51 is provided with a stop rod 54, and the other end is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com