Centrifugal oil-gas separator and engine applying same

An oil and gas separator, centrifugal technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of small scope of application, high production cost, many parts, etc., to reduce production costs, facilitate production, reduce effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

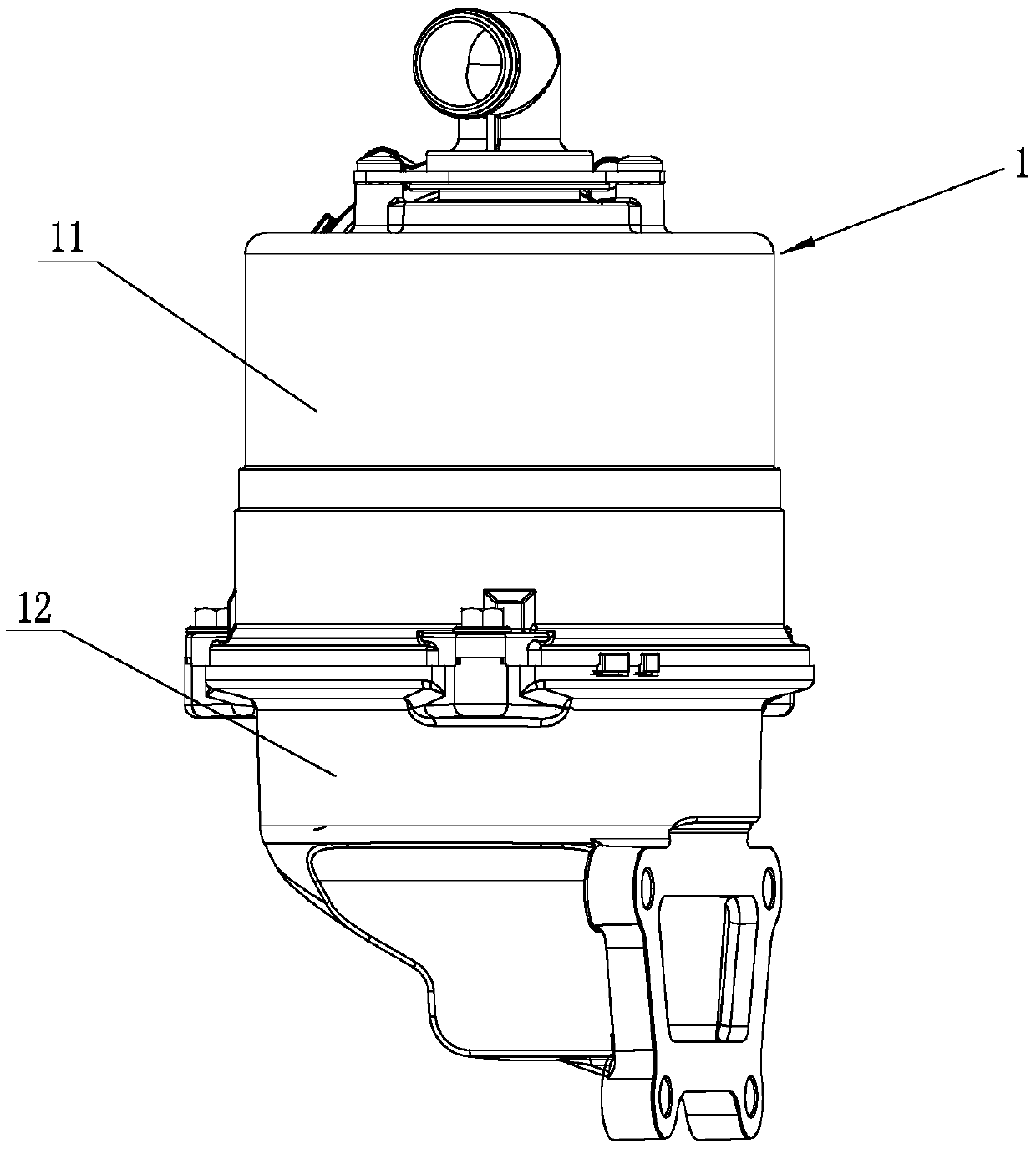

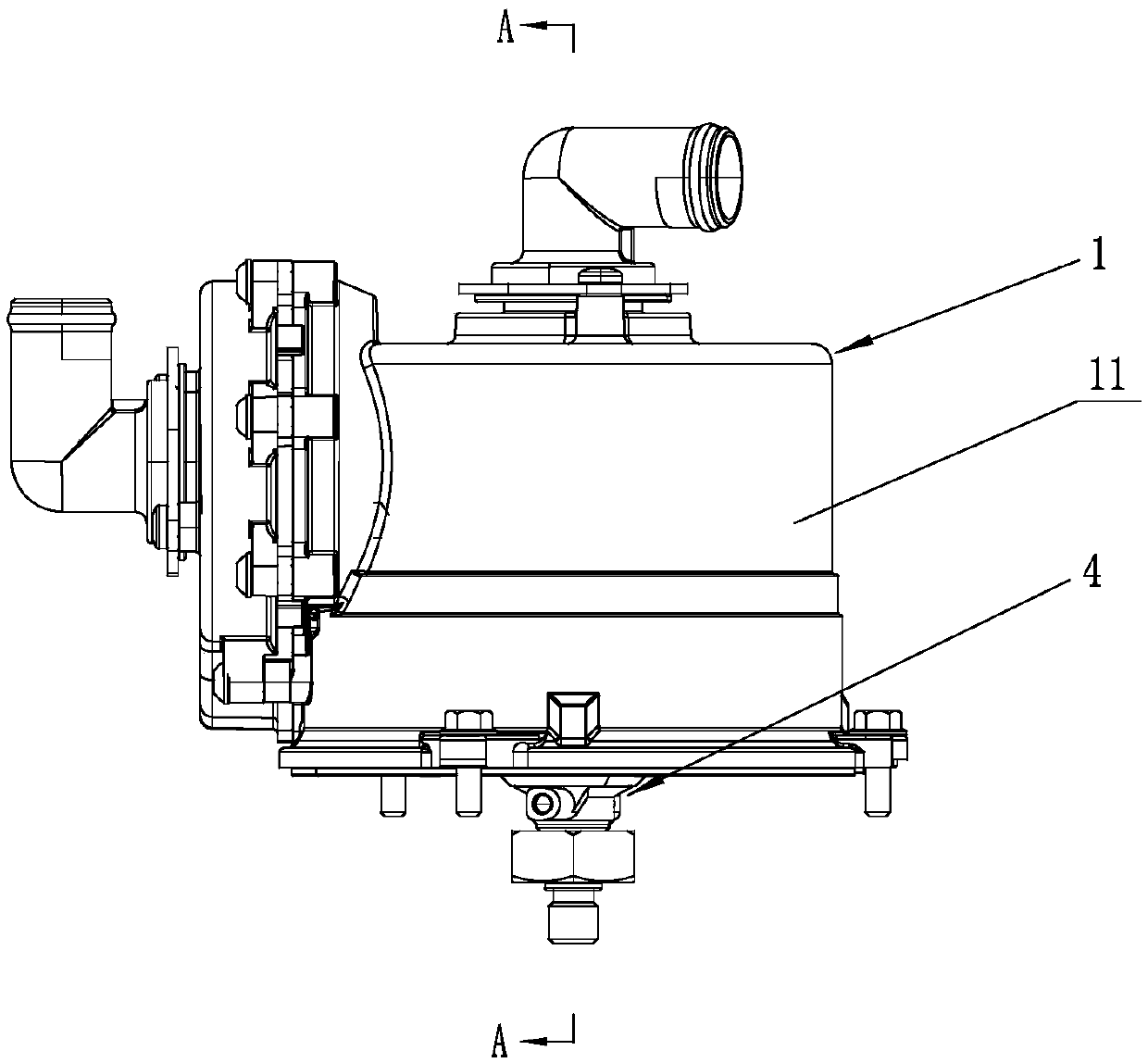

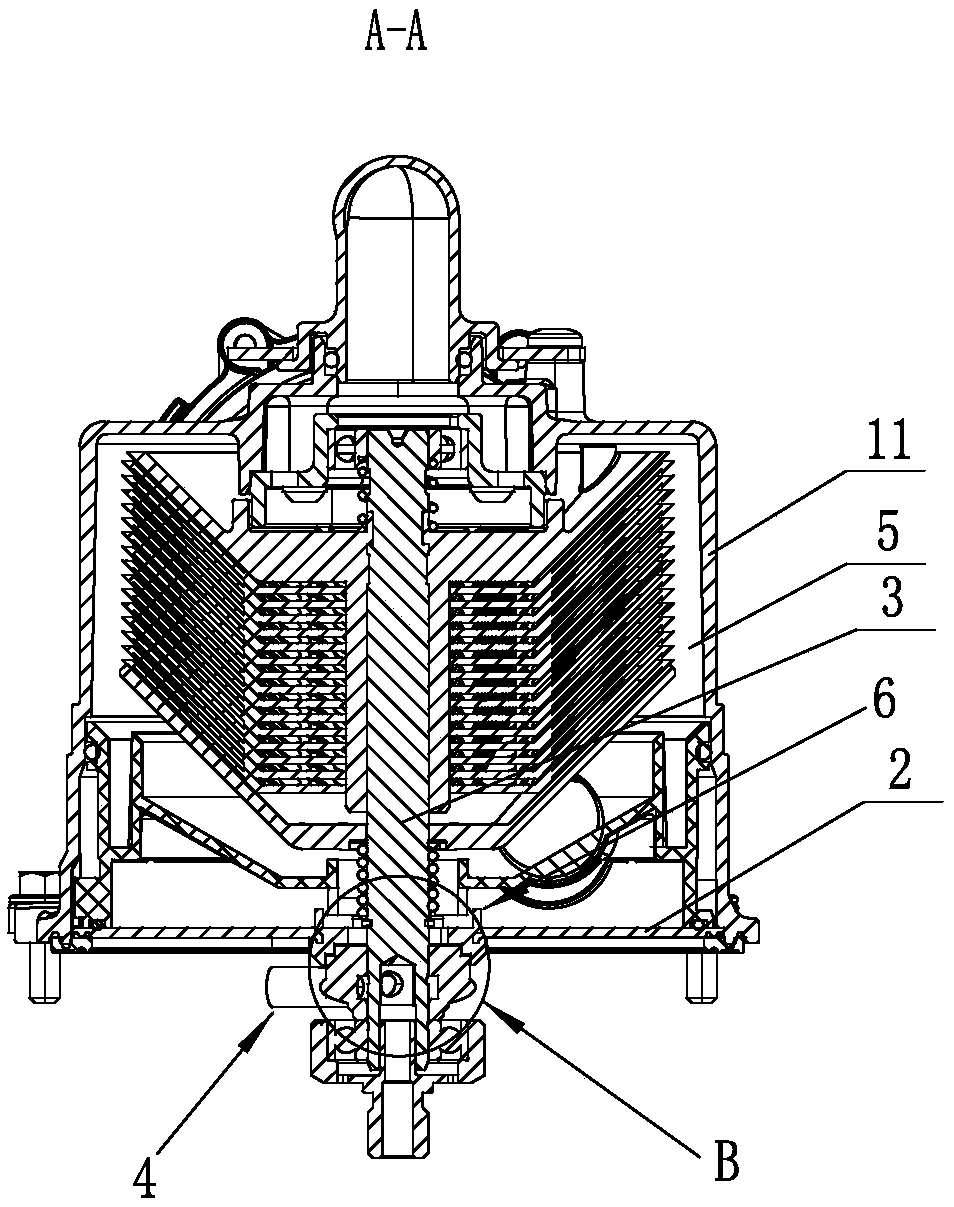

[0028] Such as Figure 1-4 Shown, a kind of centrifugal type oil-gas separator, it comprises housing 1, cavity dividing plate 2, rotating shaft 3 and drive plate 4 (certainly also comprises other components, but because the invention point that does not relate to the invention of the present invention, so in This will not be repeated), the housing 1 is divided into an upper housing 11 and a lower housing 12, the cavity partition 2 is fixed at the position between the upper housing 11 and the lower housing 12, the cavity partition 2 and the upper The inner cavity of the housing 11 forms a separation cavity 5, the cavity partition 2 and the inner cavity of the lower casing 12 form a driving chamber, and the driving disc 4 is located in the driving chamber, and the center of the cavity partition 2 is provided with a communication separation chamber. cavity 5 and the through hole of the driving chamber, and the sleeve 6 is fixedly arranged in the through hole, the upper end of the...

Embodiment 2

[0032]A kind of centrifugal oil-gas separator, it comprises casing 1, cavity dividing plate 2, rotating shaft 3 and drive plate 4 (also comprises other components of course, but because the invention point that does not relate to the invention of the present invention, so no longer here repeat), the housing 1 is divided into an upper housing 11 and a lower housing 12, the cavity partition 2 is fixed at a position between the upper housing 11 and the lower housing 12, the cavity partition 2 and the upper housing 11 The inner cavity of the cavity forms a separation cavity 5, the inner cavity of the cavity partition plate 2 and the lower housing 12 forms a drive chamber, and the drive disc 4 is located in the drive chamber, and the center of the cavity partition plate 2 is provided with a communication separation cavity 5 and The through hole of the drive chamber, and the sleeve 6 is fixedly arranged in the through hole, the upper end of the rotating shaft 3 is rotatably matched w...

Embodiment 3

[0036] Such as Figure 5 Shown, a kind of centrifugal type oil-gas separator, it comprises housing 1, cavity dividing plate 2, rotating shaft 3 and drive plate 4 (certainly also comprises other components, but because the invention point that does not relate to the invention of the present invention, so in This will not be repeated), the housing 1 is divided into an upper housing 11 and a lower housing 12, the cavity partition 2 is fixed at the position between the upper housing 11 and the lower housing 12, the cavity partition 2 and the upper The inner cavity of the housing 11 forms a separation cavity 5, the cavity partition 2 and the inner cavity of the lower casing 12 form a driving chamber, and the driving disc 4 is located in the driving chamber, and the center of the cavity partition 2 is provided with a communication separation chamber. cavity 5 and the through hole of the driving chamber, and the sleeve 6 is fixedly arranged in the through hole, the upper end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com