Cryogenic storage tank with axial load bearing and limiting functions

A low-temperature storage tank and axial technology, applied in the field of storage and transportation of low-temperature liquefied gas, can solve problems such as local stress concentration and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following examples.

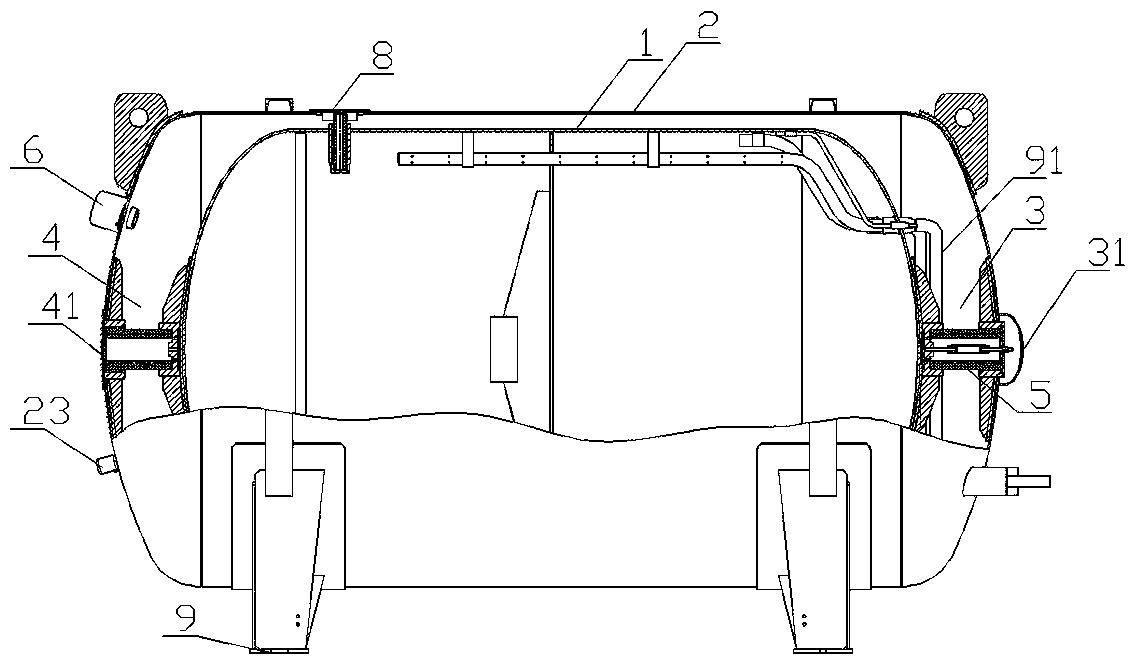

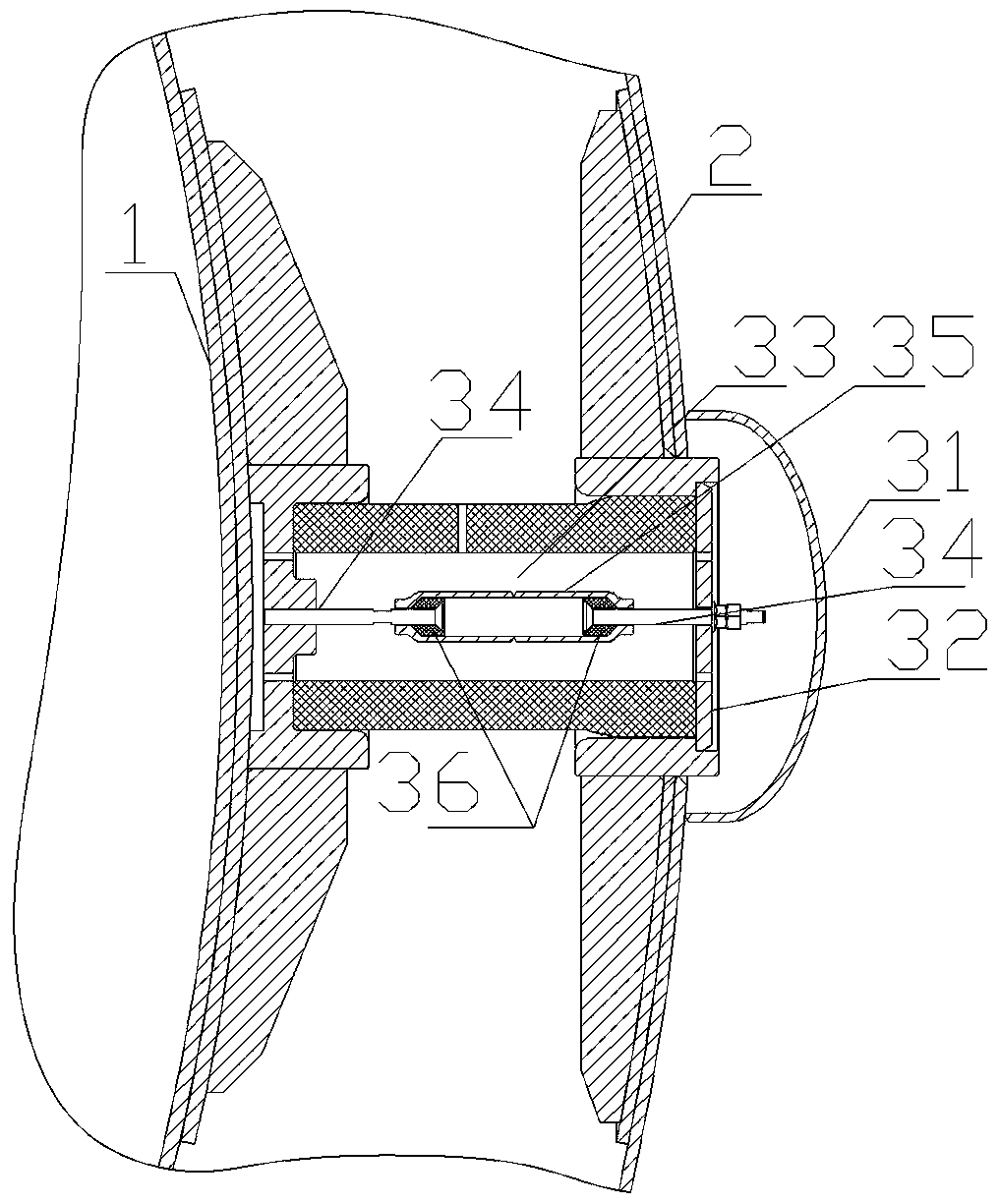

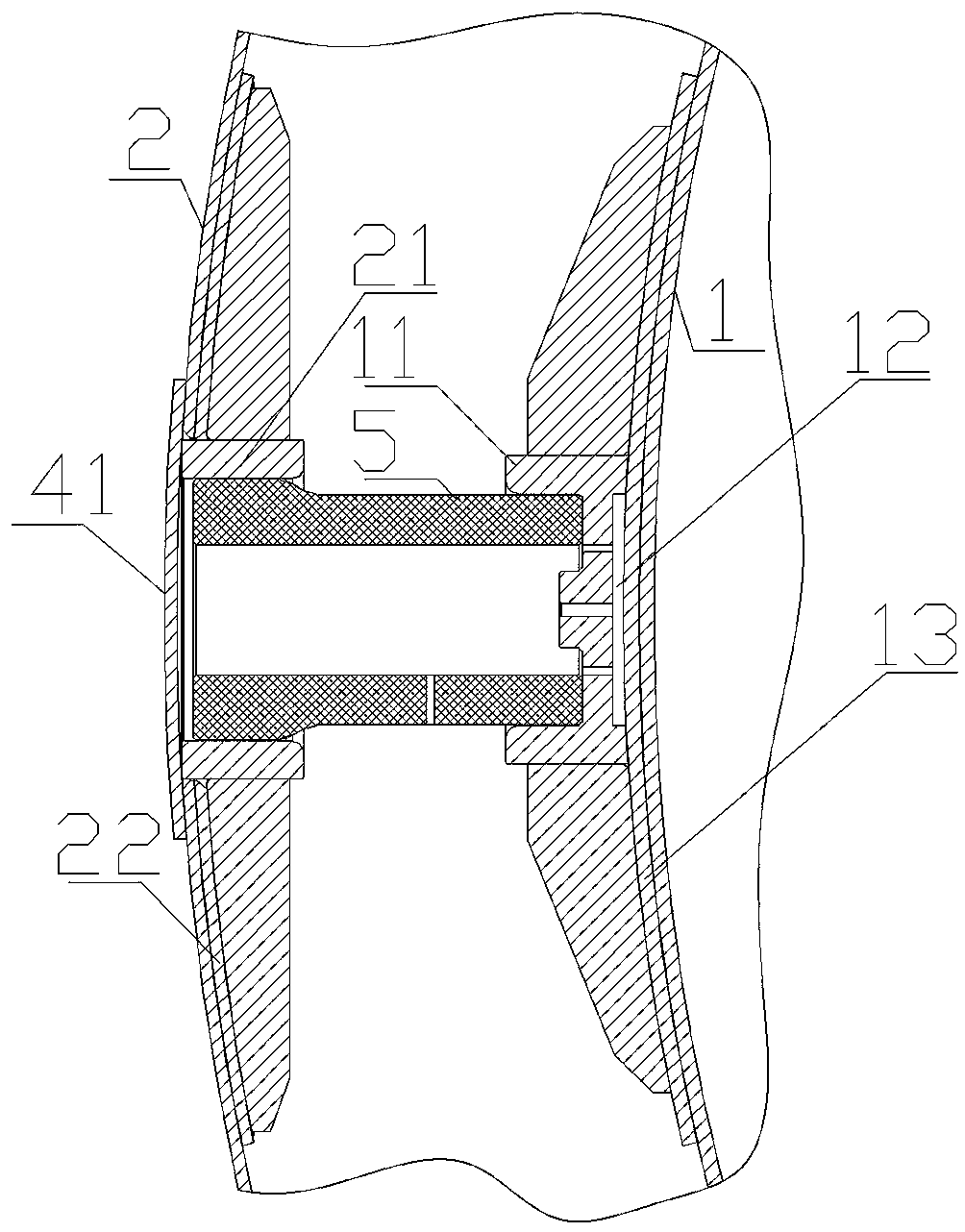

[0028] See attached Figure 1~6 . A low-temperature storage tank with axial load-bearing and position-limiting functions, comprising an inner container 1, an outer shell 2, a fixed part 3 and a sliding part 4; In the shell 2; the fixed part 3 keeps the distance between the inner container 1 and the shell 2 constant; the sliding part 4 makes the distance between the inner container 1 and the shell 2 variable; The sealing cover head 31 and the cover plate 41 sealing the sliding part 4 .

[0029] Due to the above structure, the gravitational load of the inner container 1 and the medium is transmitted to the outer shell 2 through the fixed part 3 and the sliding part 4, and the fixed part 3 can prevent one end of the inner container 1 from being displaced relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com