Image inspection apparatus and computer-readable recording medium storing a program

A technology for image inspection and recording medium, which is applied in the direction of electric recording process applying charge pattern, equipment and calculation of electric recording process applying charge pattern, etc. Inability to cope with small changes in conveying speed magnification, etc., to achieve the effect of shortening the time, real-time inspection, and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach example >

[0033] Hereinafter, a first embodiment example of the present invention will be described.

[0034] [1-1. Structure of image inspection device]

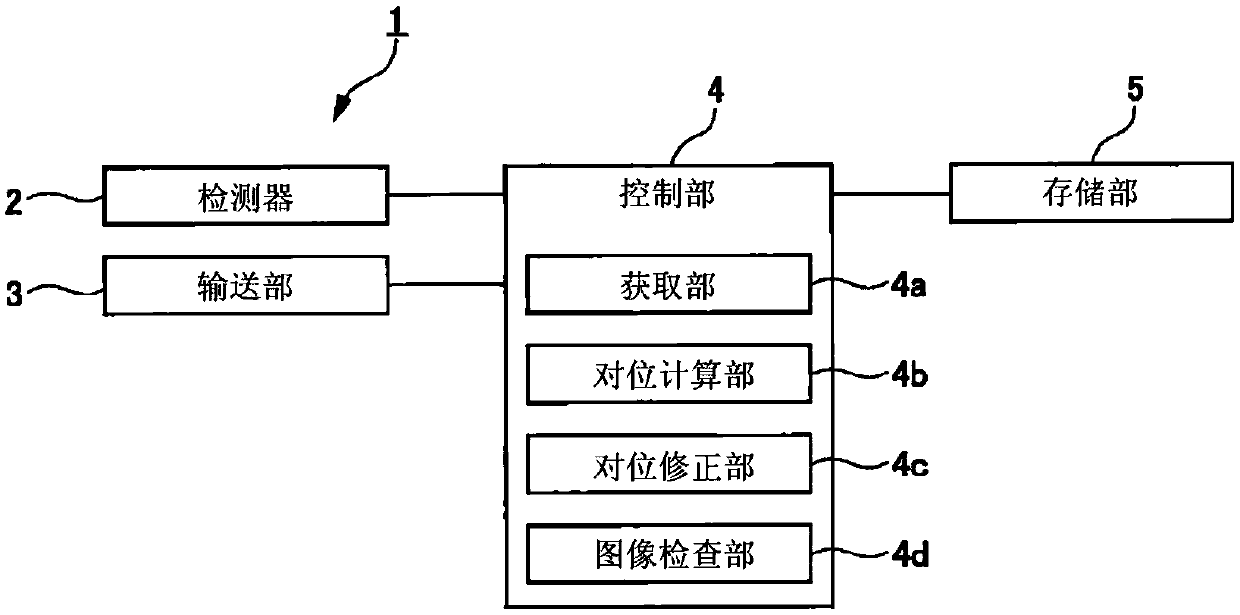

[0035] figure 1 is a functional block diagram of the image inspection device 1 .

[0036] The image inspection apparatus 1 includes: a detector 2 having a linear image sensor that reads an image formed on a sheet; a transport unit 3 that outputs the sheet in conjunction with reading by the detector 2; and a control unit 4 that controls the overall image inspection process. and a storage unit 5 storing data (correction parameters, etc.) necessary for the control unit 4 to perform control.

[0037] The control unit 4 includes an acquisition unit 4a, an alignment calculation unit 4b, an alignment correction unit 4c, and an image inspection unit 4d.

[0038] The acquiring unit 4a acquires the figure 2 ) data of an output target image for image formation on paper. In the following description, an output target image is referred to a...

no. 2 approach example >

[0090] Next, a second embodiment example of the present invention will be described.

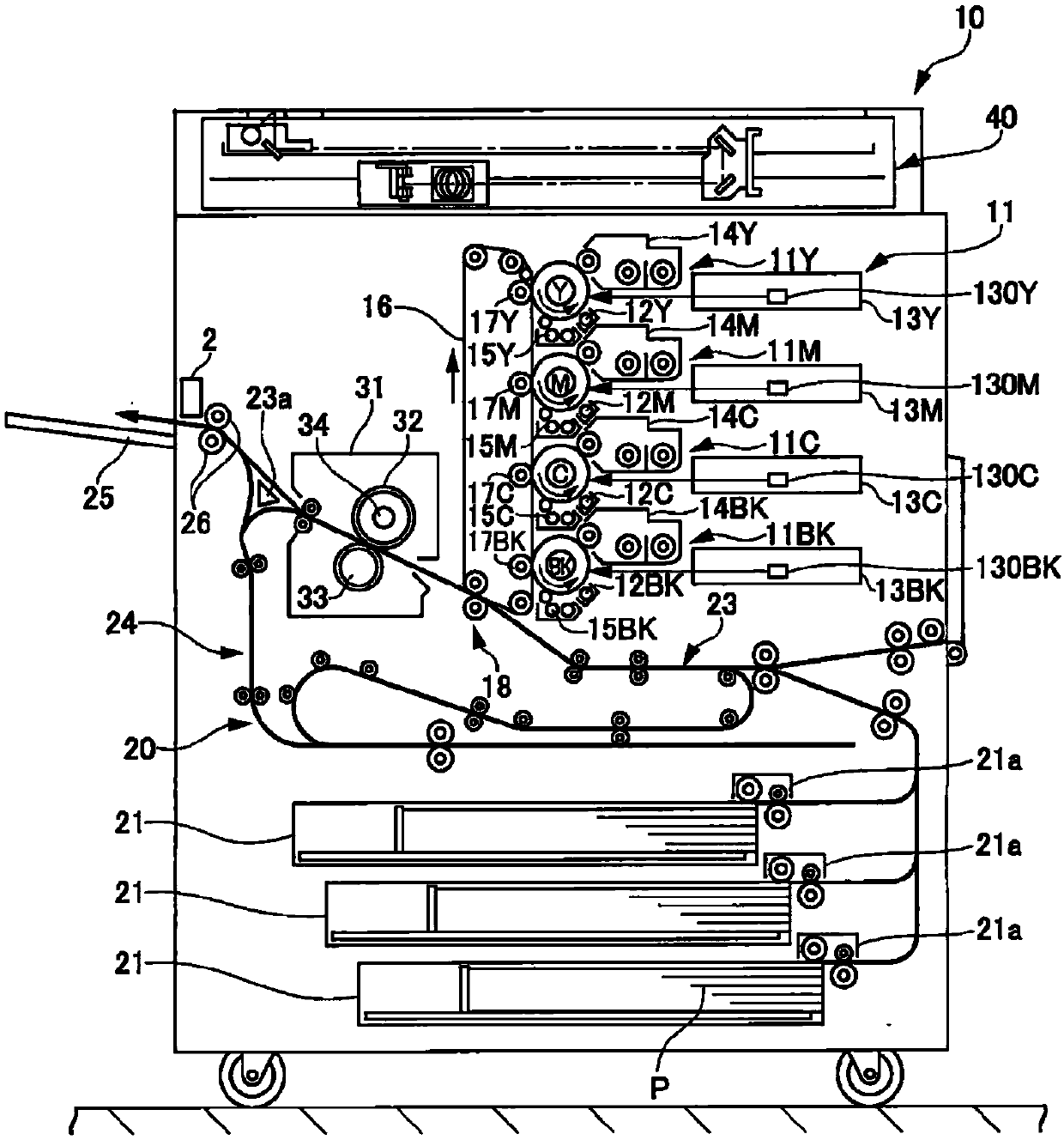

[0091] Also in the second embodiment, the image inspection apparatus 1 and the image forming apparatus 10 are applied as they were described in the first embodiment. figure 1 as well as figure 2 structure shown.

[0092] In the second embodiment, as described below, the flow of processing at the time of proof printing and mass printing is different from that of the first embodiment. In the second embodiment example, in Image 6 In the variable region V and the non-variable region NV described above, different contamination detection processes are performed at the time of mass printing.

[0093] below Figure 8 as well as Figure 9 The image inspection process shown in the flowchart of is executed by, for example, the CPU constituting the control unit 4 .

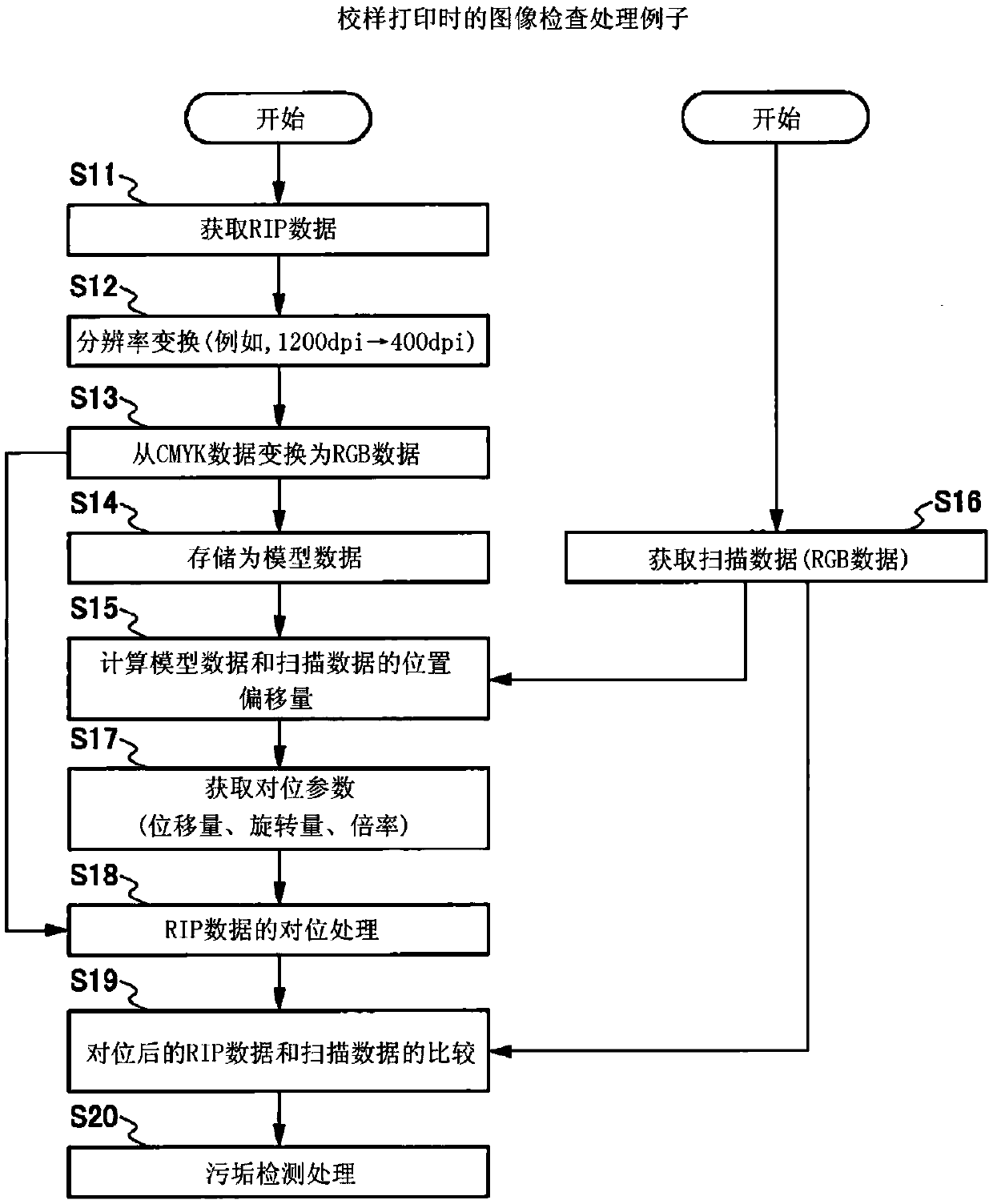

[0094] [2-1. Image inspection processing (during proof printing)]

[0095] Figure 7 It is a flowchart showing the flow of image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com