Bale opener

A technology of bale unpacking machine and catching roller, which is applied in fiber unpacking, textile and paper making, fiber processing, etc., and can solve problems such as difficulty in setting up cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

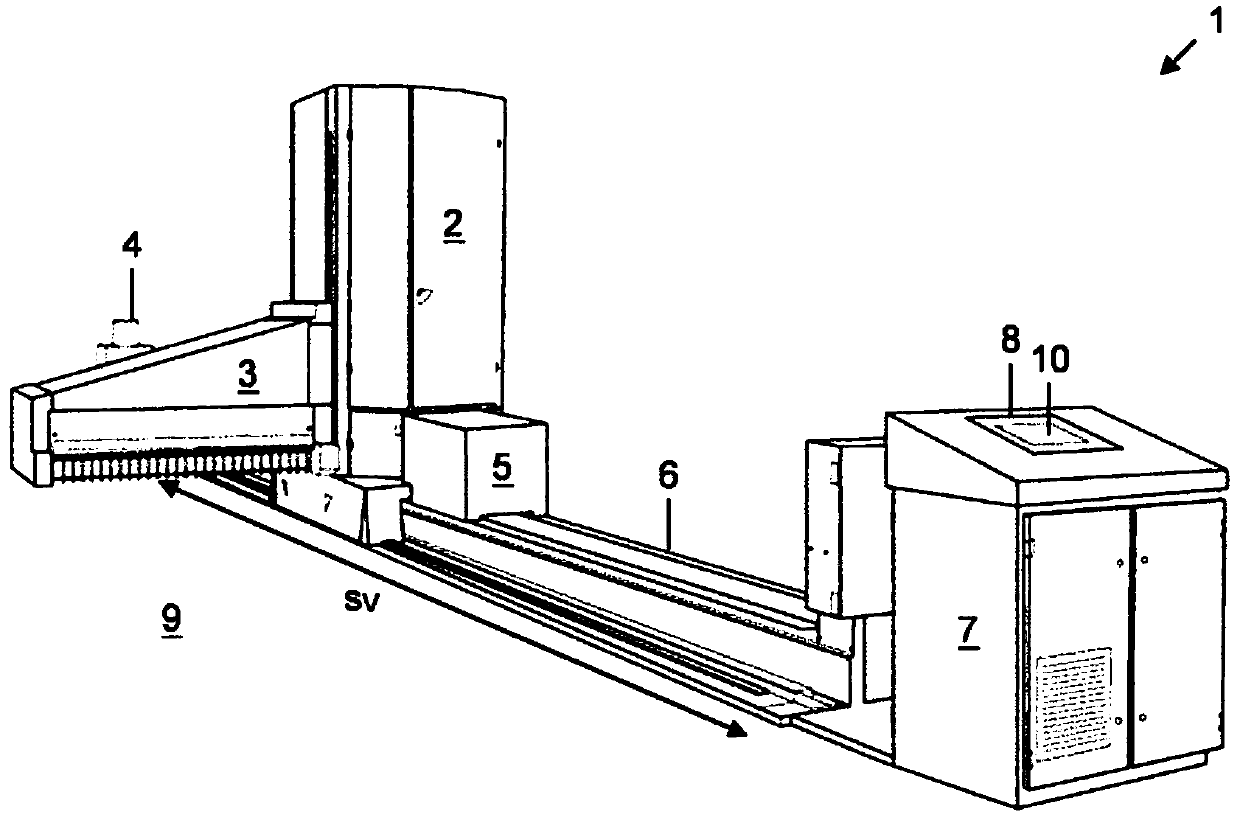

[0024] figure 1 A bag opening machine 1 is shown as an example. In a known manner, the bale opener has a pick-up device 3 which can be moved back and forth along the movement or stripping path Sv. The catching device 3 has, in a known manner, a catching roller on its side facing the ground 9, by means of which the bale opener 1 can catch a fiber bale, not shown here, and then open it from the fiber bale. Loose fiber material, the fiber bales are arranged in rows along the movement or stripping path Sv.

[0025] The opened fiber material is conveyed via a suction mechanism located inside the housing 2 to a downstream fiber discharge device 4 and is guided, for example, via a pipe system to a downstream machine, such as a cleaning machine.

[0026] The housing 2 together with the catching device 3 is preferably rotatable about an axis extending perpendicularly to the ground 9 . Furthermore, for moving the catching device 3 back and forth along the above-mentioned fiber bale, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com