Method for handling a wind turbine blade

A technology of blades and pulleys, which is applied in the field of installation and removal of wind turbine blades, and can solve problems such as complicated operation and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

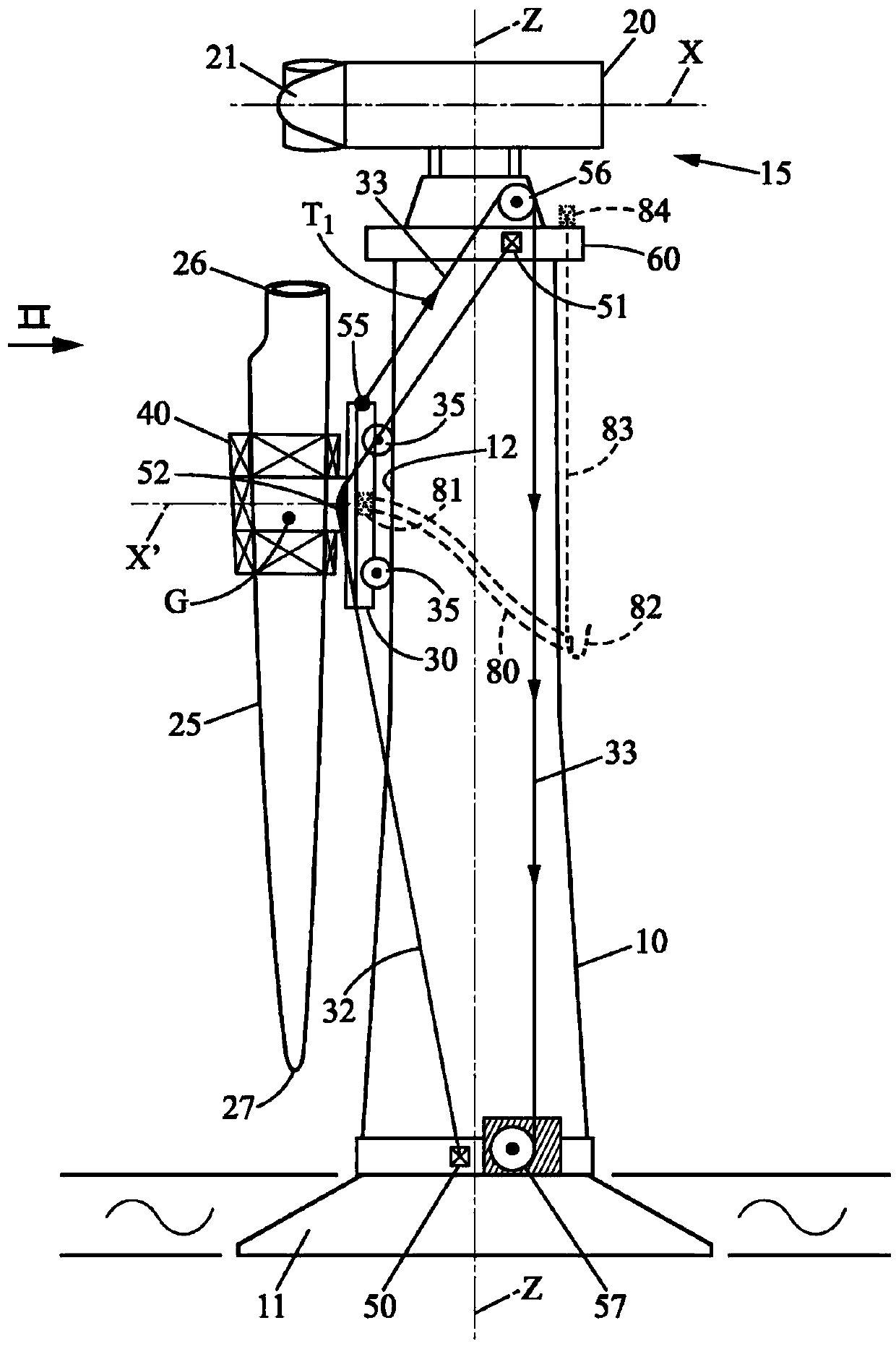

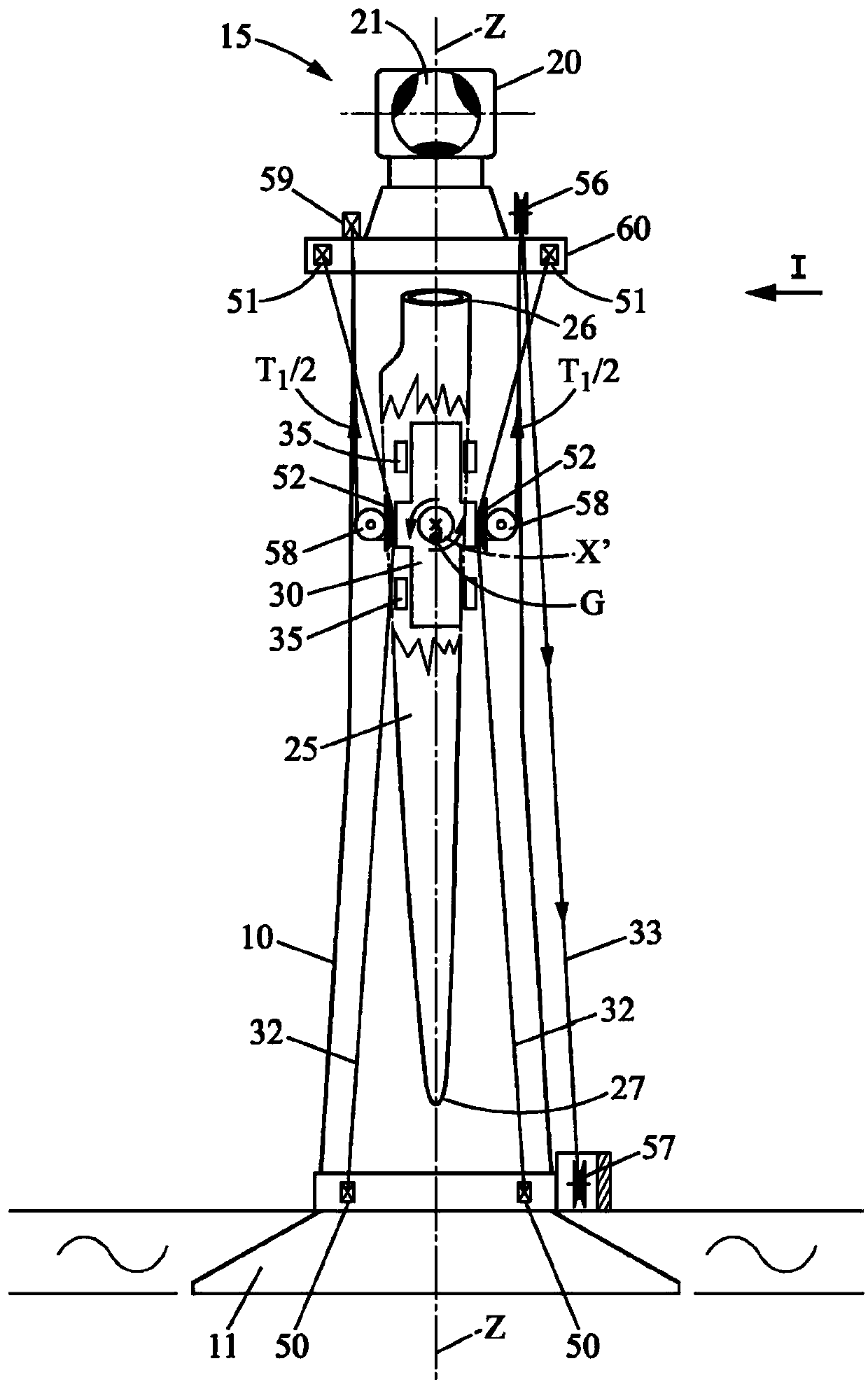

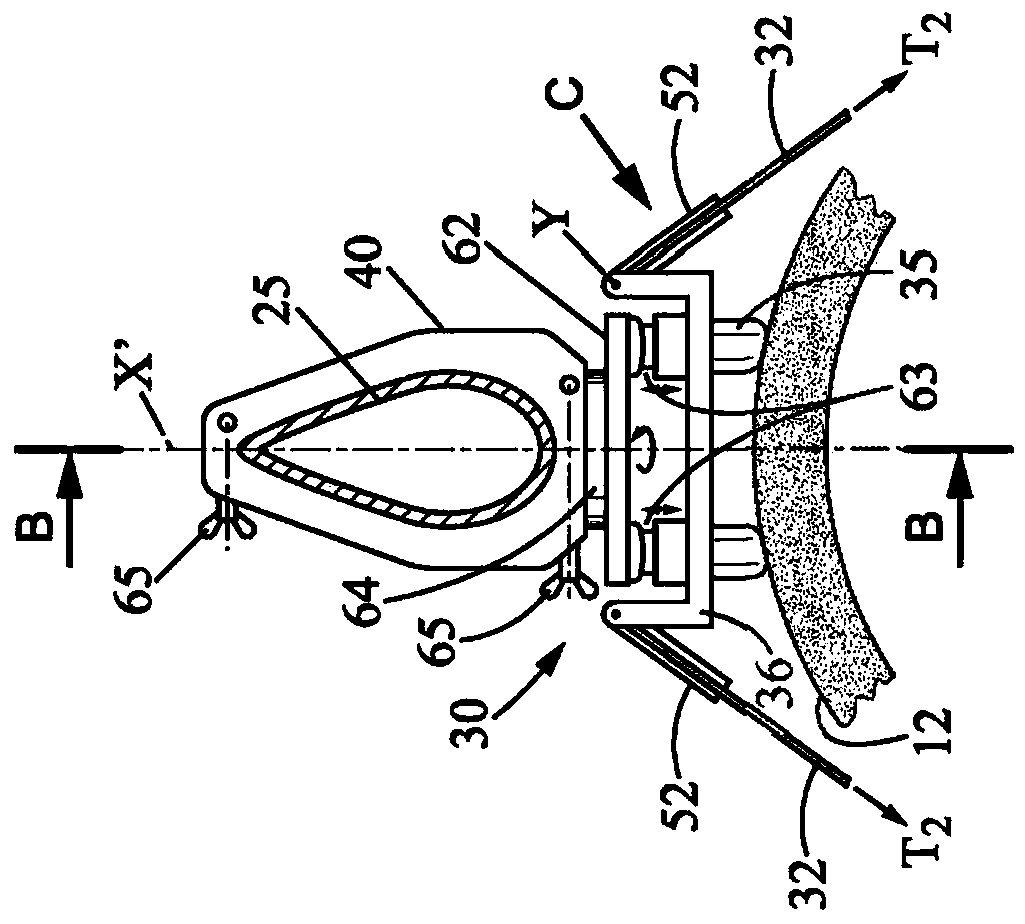

[0031] figure 1 with figure 2 The illustration shows a wind turbine with a tower 10 with a nacelle 15 on top. To facilitate the reading of these two figures, the horizontal dimension of the wind turbine tower has been enlarged relative to its vertical dimension. In fact, the vertical dimension of the tower, for example about 150 m, is 10 times larger than its horizontal dimension.

[0032] The tower 10 stands on a foundation 11 built in the ground. Generally, the tower 10 is made by assembling precast concrete elements over its entire height or part of its height. The concrete members are prestressed by vertical cables (not shown) to ensure that the tower 10 has good bending resistance to the bending force exerted on it by the wind.

[0033] The top of the tower 10 is assembled to accommodate a nacelle 15 having a base pivoting about the vertical axis Z of the tower. The purpose of the nacelle 15 is to house the generator 20 of the wind turbine, the rotor of which has a hub 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com