Position actuator having pneumatic ventilation

A technology for actuators and ventilation devices, applied to components with teeth, transmission device control, fluid pressure actuation devices, etc., can solve complex and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

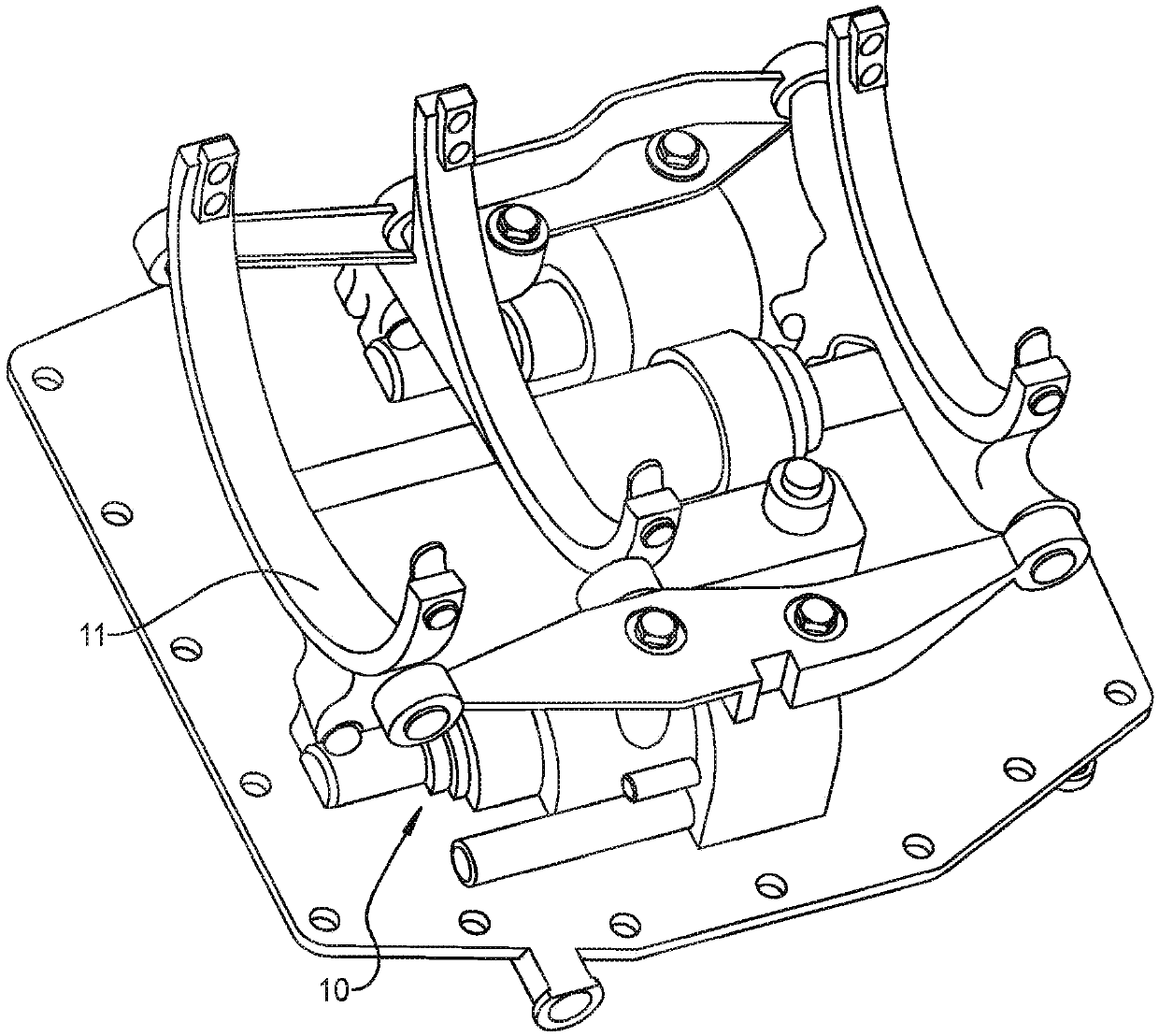

[0025] Such as Figure 1 to Figure 13 One embodiment of a position actuator 10 with pneumatic ventilation according to the present invention is shown for moving components of a vehicle powertrain (not shown), such as those located in an automatic transmission or an automated manual transmission, as disclosed in Pneumatic shift or position actuators for gears and clutches. exist figure 1 In the illustrated embodiment, a position actuator 10 is used to move a shift rail 11 to engage and disengage at least one gear in the transmission. It should be understood that the position actuator 10 may be used in other embodiments for vehicles other than powertrains. It should also be understood that the position actuator 10 may be a two-position actuator or a three-position actuator.

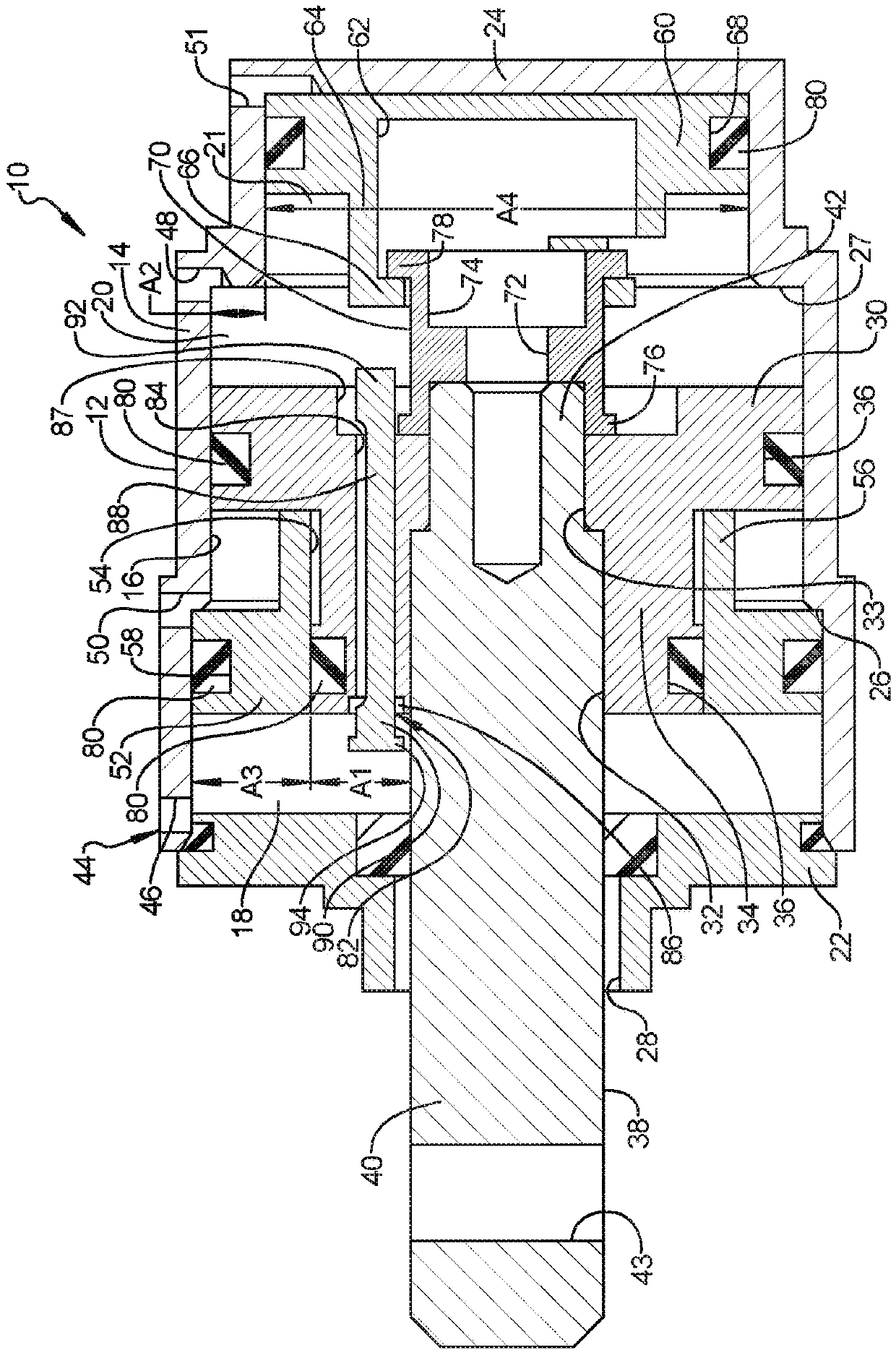

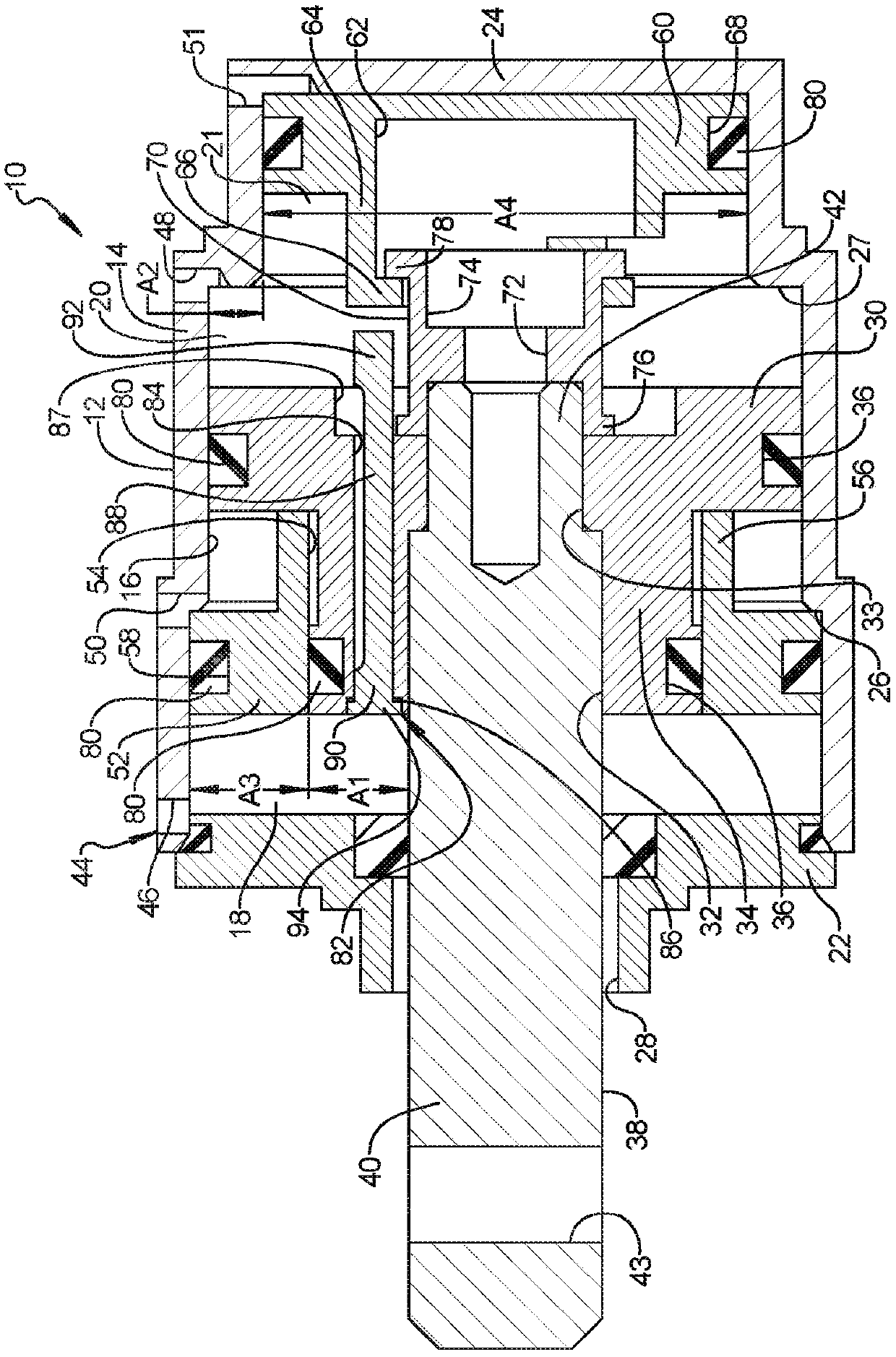

[0026] refer to Figure 2-13 , the position actuator 10 includes an axially extending cylinder housing 12 . The cylinder housing 12 is generally cylindrical with a generally circular cross-section. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com