Surface wiper of machining center machine tool

A processing center and wiper technology, applied to dryers, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of low wiping efficiency and easy reflection on people, so as to improve wiping efficiency and speed up drying speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

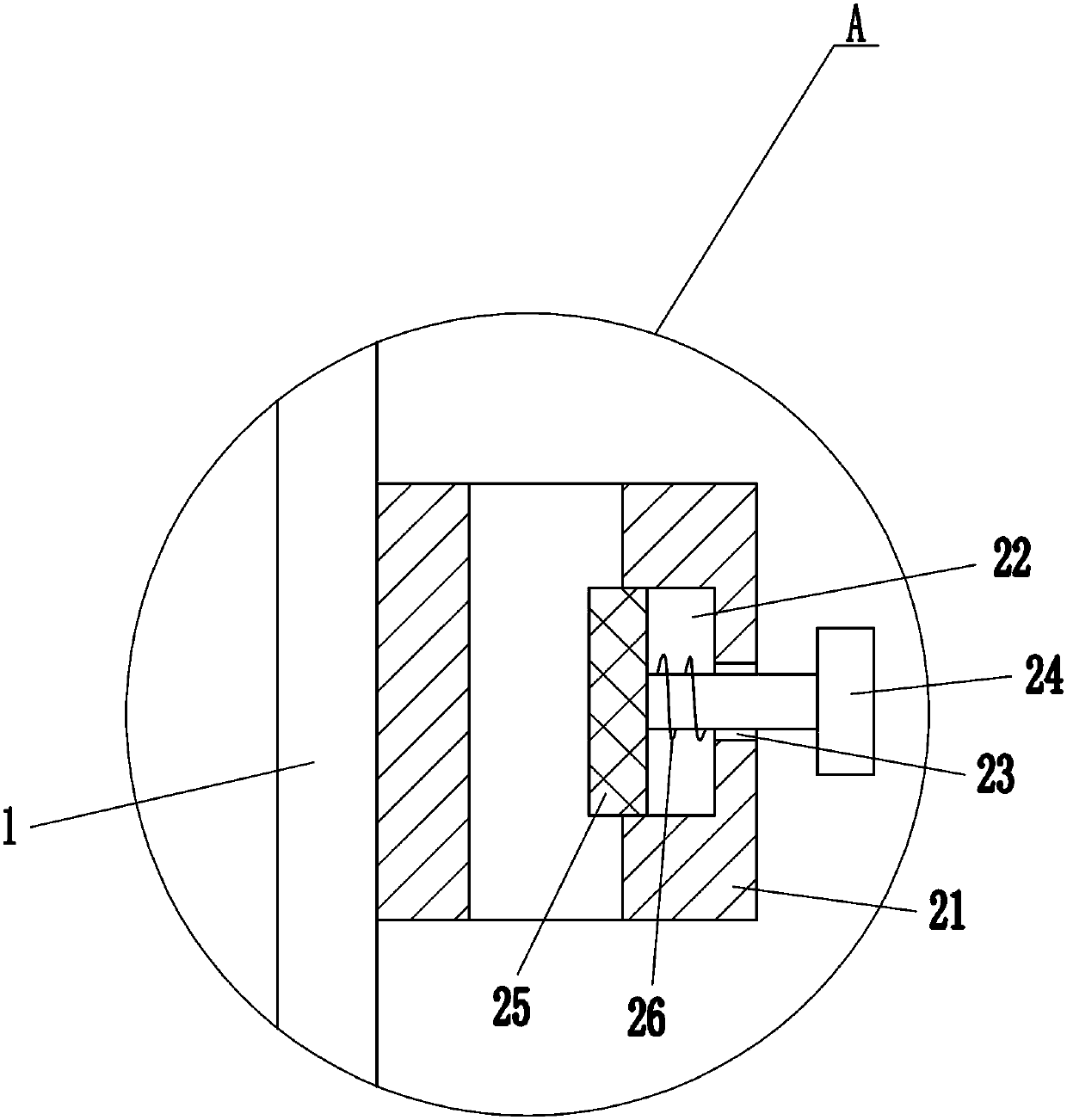

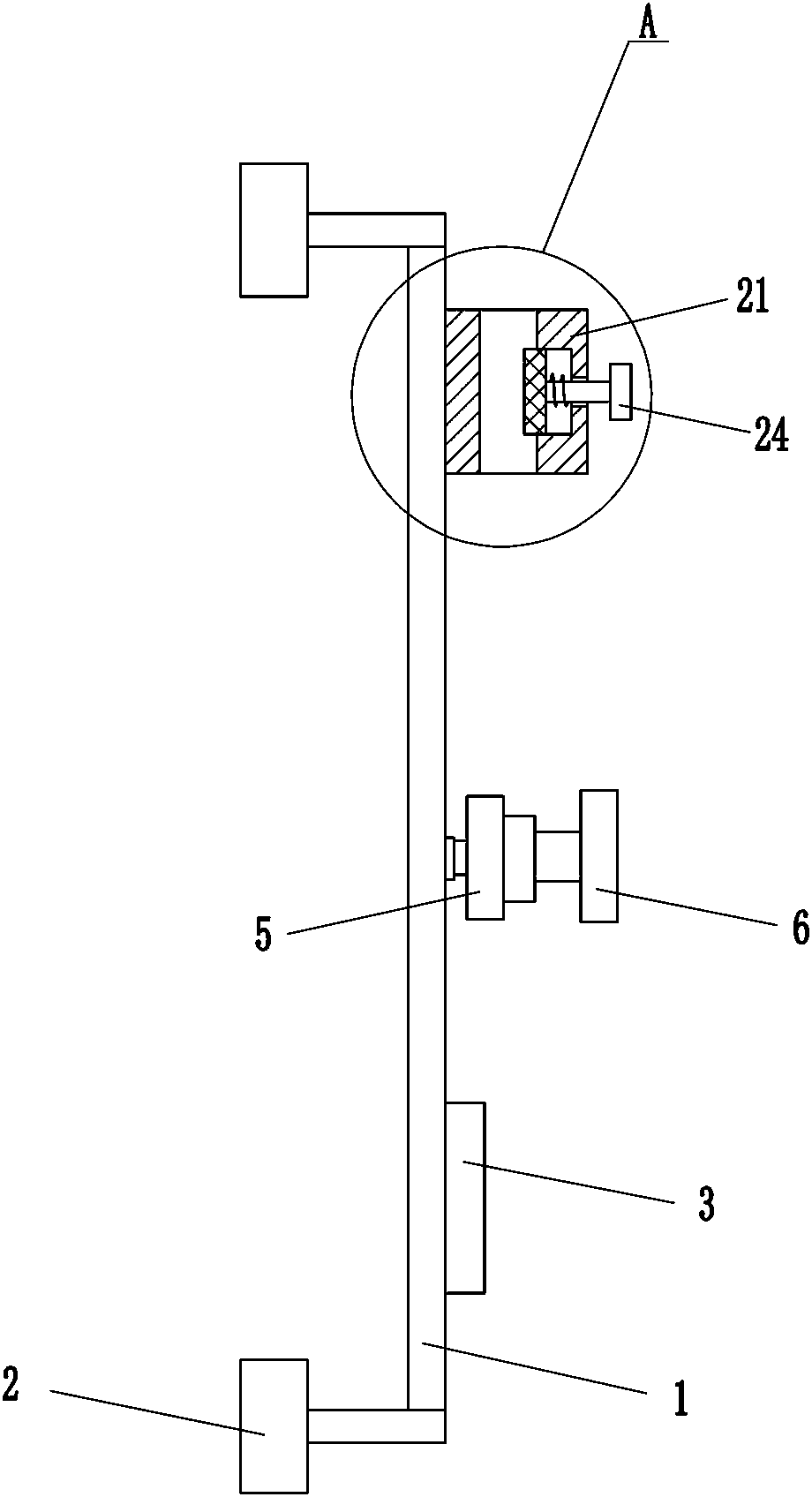

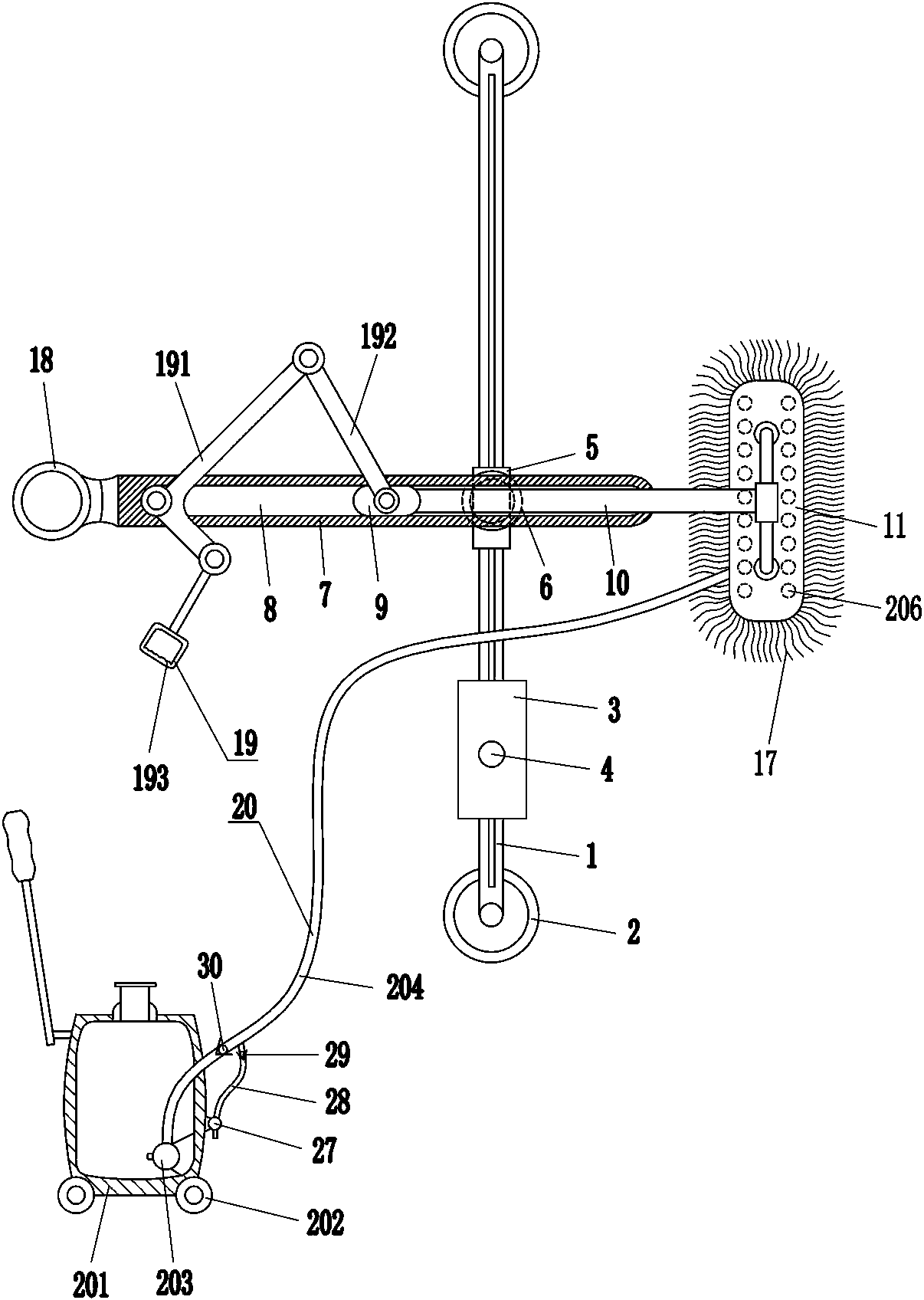

[0017] A machining center machine tool surface wiper, such as Figure 1-3 As shown, it includes a slide rail 1, an electromagnet 2, a power supply 3, a switch 4, a slider 5, a rotating shaft 6, a movable plate 7, a slider 9, a moving rod 10, a mounting block 11, a screw 13, a mesh plate 14, and a nut 16. Hairbrush 17, handle 18 and driving mechanism 19, the upper and lower ends of slide rail 1 are bolted with electromagnet 2, the lower part of the front side of slide rail 1 is bolted with power supply 3, and the front side of power supply 3 is installed with electromagnet 2 for controlling The switch 4, the switch 4 is connected with the power supply 3, the two electromagnets 2 are connected with the switch 4, the slide rail 1 is provided with a sliding block 5 which plays a guiding role, and the slide block 5 is located above the power supply 3, The front side of the slider 5 is rotatably connected with a T-shaped rotating shaft 6, and the movable plate 7 is fixedly connected...

Embodiment 2

[0019] A machining center machine tool surface wiper, such as Figure 1-3 As shown, it includes a slide rail 1, an electromagnet 2, a power supply 3, a switch 4, a slider 5, a rotating shaft 6, a movable plate 7, a slider 9, a moving rod 10, a mounting block 11, a screw 13, a mesh plate 14, and a nut 16. Hairbrush 17, handle 18 and driving mechanism 19, the upper and lower ends of slide rail 1 are bolted with electromagnet 2, the lower part of the front side of slide rail 1 is bolted with power supply 3, and the front side of power supply 3 is installed with electromagnet 2 for controlling The switch 4, the switch 4 is connected with the power supply 3, the two electromagnets 2 are connected with the switch 4, the slide rail 1 is provided with a sliding block 5 which plays a guiding role, and the slide block 5 is located above the power supply 3, The front side of the slider 5 is rotatably connected with a T-shaped rotating shaft 6, the movable plate 7 is fixedly connected to ...

Embodiment 3

[0022] A machining center machine tool surface wiper, such as Figure 1-3 As shown, it includes a slide rail 1, an electromagnet 2, a power supply 3, a switch 4, a slider 5, a rotating shaft 6, a movable plate 7, a slider 9, a moving rod 10, a mounting block 11, a screw 13, a mesh plate 14, and a nut 16. Hairbrush 17, handle 18 and driving mechanism 19, the upper and lower ends of slide rail 1 are bolted with electromagnet 2, the lower part of the front side of slide rail 1 is bolted with power supply 3, and the front side of power supply 3 is installed with electromagnet 2 for controlling The switch 4, the switch 4 is connected with the power supply 3, the two electromagnets 2 are connected with the switch 4, the slide rail 1 is provided with a sliding block 5 which plays a guiding role, and the slide block 5 is located above the power supply 3, The front side of the slider 5 is rotatably connected with a T-shaped rotating shaft 6, the movable plate 7 is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com