Oil separator hole drawing method and hole drawing die processing method

A technology for oil separators and workpieces, which is applied to manufacturing tools, furnace types, furnaces, etc., can solve the problems of difficulty in drawing and flanging of welding holes, different wall thicknesses, and uneven heights, so as to improve the efficiency of drawing holes and achieve accurate shapes. , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

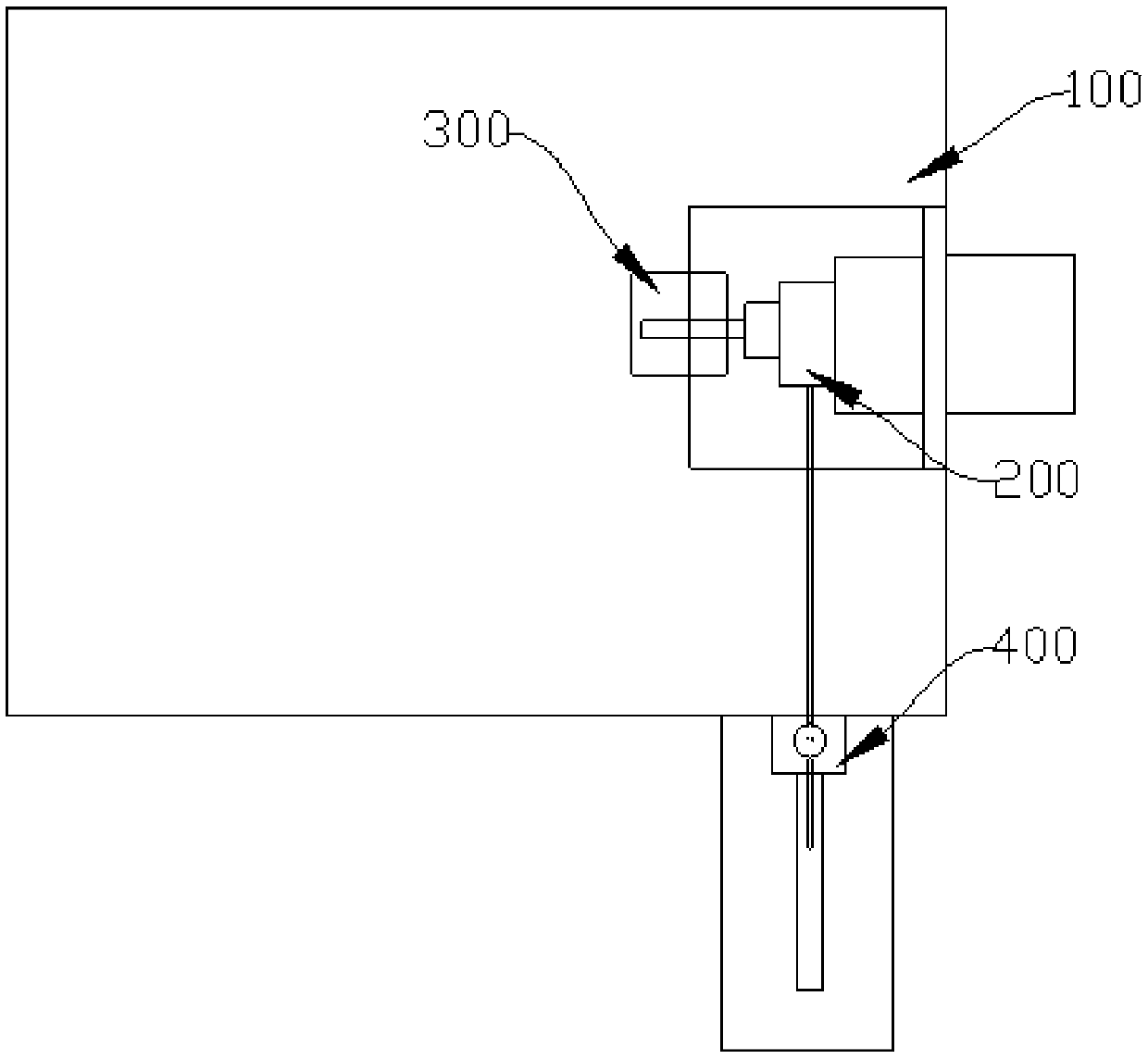

[0082] Such as figure 1 As shown, a hole pulling device for an oil separator includes a hole pulling machine 100 , a drawing die 200 and a clamping die 300 . Wherein, the hole pulling machine 100 and the drafting mold 200 cooperate with each other, and are used for pulling the hole and flanging the oil separator; the clamping mold 300 is used to fix the oil separator on the drafting mold 200, so that the hole pulling machine 100 and the The drawing mold 200 can smoothly perform the hole-drawing and flanging operation on the oil separator, preventing the oil separator from shaking during the hole-drawing process, thereby affecting the hole-drawing efficiency and hole-drawing accuracy. The specific structures of the hole pulling machine 100 , the pulling die 200 and the clamping die 300 will be described in detail below.

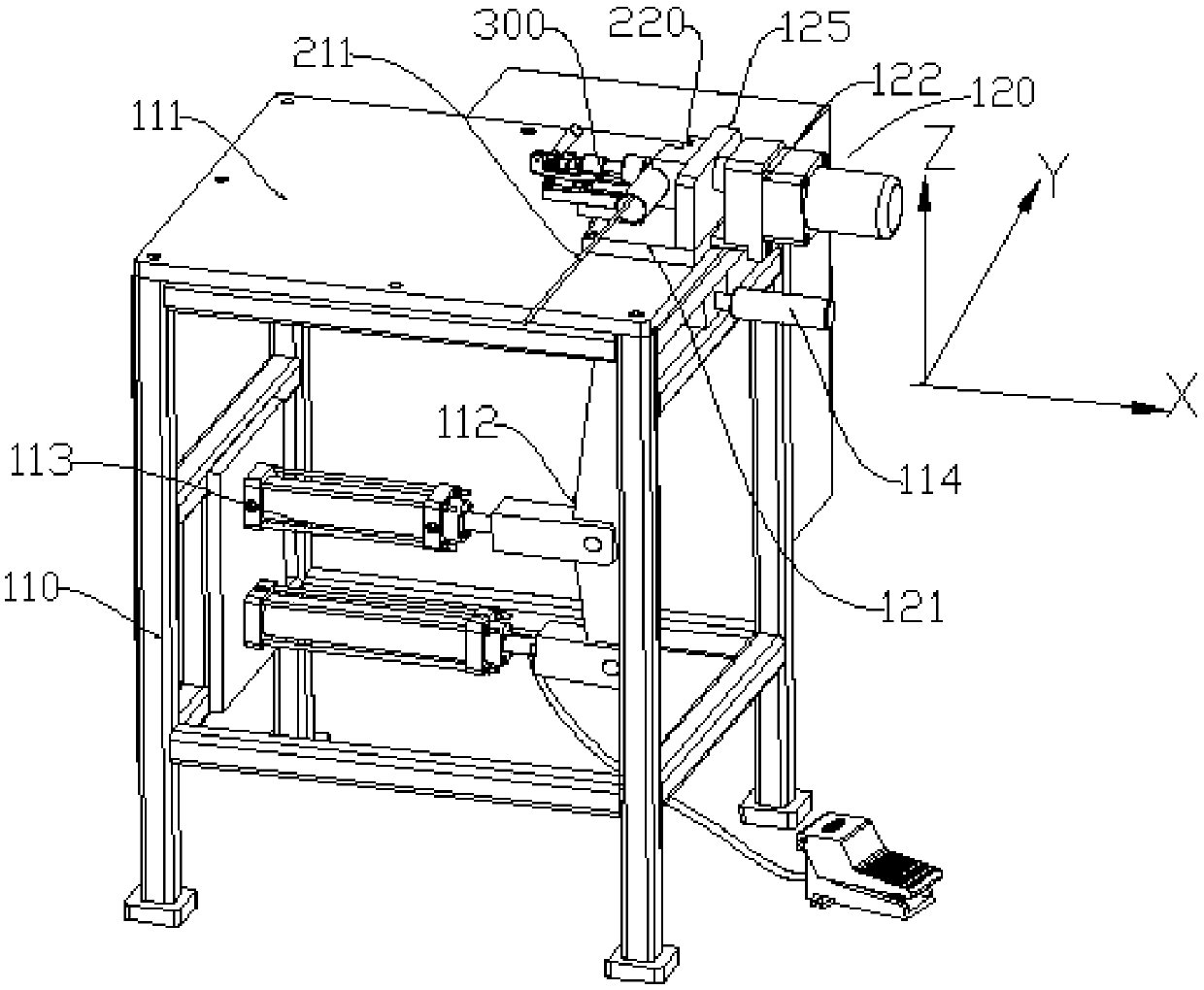

[0083] Such as Figure 2 to Figure 5 As shown, the hole pulling machine 100 includes a frame 110 and a hole pulling device 120 installed on the frame 110 . ...

Embodiment 2

[0090] In the specific hole-drawing process of the oil separator hole-pulling device in Example 1, the hole-pulling head 210 may not be connected to the output shaft of the motor 122 quickly and accurately, thereby affecting the hole-pulling efficiency and hole-pulling accuracy. Therefore, this embodiment provides a positioning device 400 on the basis of Embodiment 1, which can accurately and quickly connect the pulling head 210 to the output shaft of the motor 122, thereby improving the hole pulling efficiency and hole pulling accuracy.

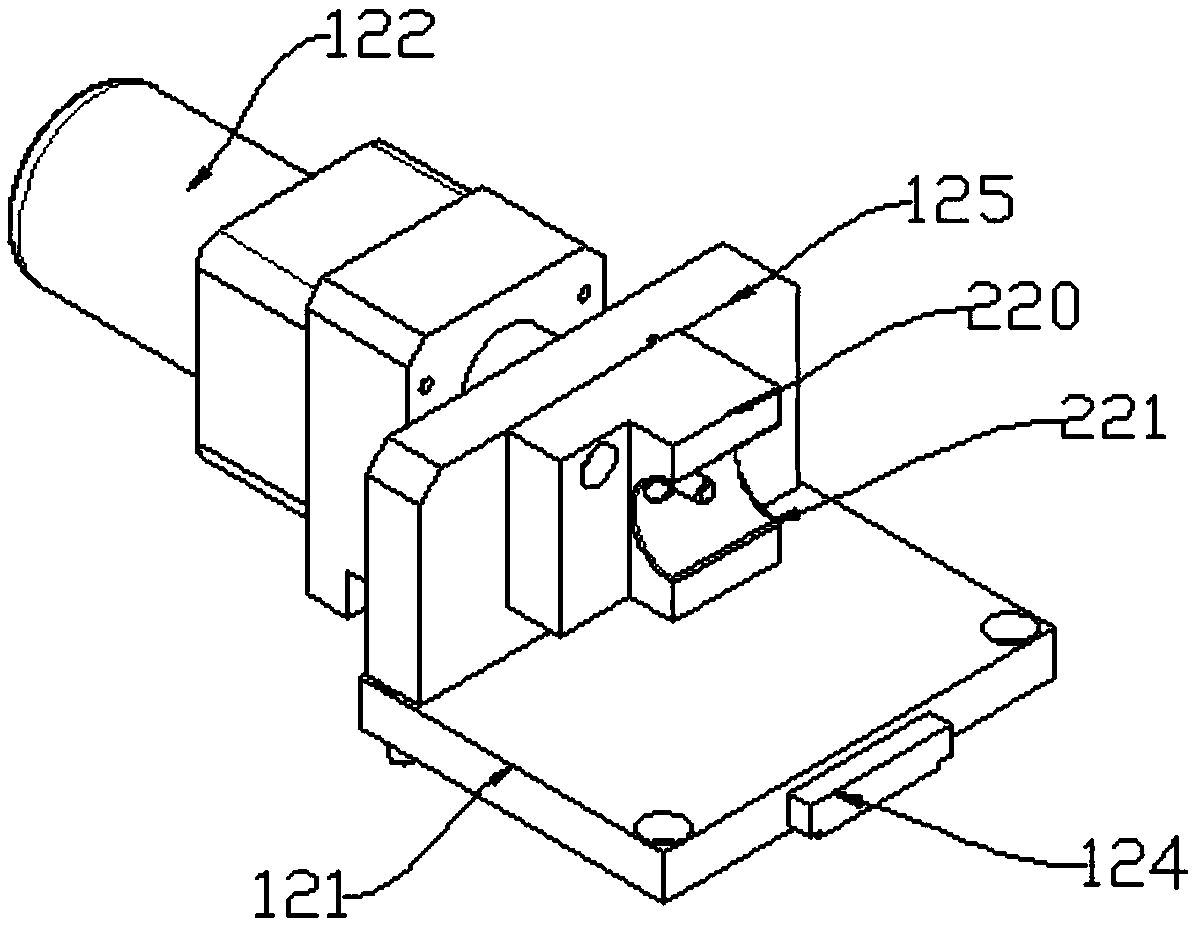

[0091] Such as figure 1 , Figure 9 and Figure 10 As shown, the positioning device 400 includes a slide table 410 and a slide seat 420 . Wherein, the slide table 410 is installed in the Y-axis direction where the fixed mold 220 is located on the upper plate 111, and is a rectangular plate-shaped structure, on which a guide groove 411 is arranged along the Y-axis direction. The slide seat 420 is a rectangular block structure, and its lowe...

Embodiment 3

[0093] This embodiment provides a method for pulling holes in an oil separator. The oil separator hole pulling equipment in Embodiment 2 is used to pull holes and flanging operations on the oil separator. The hole pulling efficiency is high, and the wall thickness of the processed flanging is uniform. , highly consistent, the specific process of the hole pulling method will be described in detail below.

[0094] 1. Head positioning

[0095] Before the hole pulling equipment starts to work, the pulling head 210 needs to be positioned at the working position of hole pulling. The specific process of the positioning operation is as follows:

[0096] Make the sliding seat 420 move along the Y-axis direction on the sliding table 410 through the guide groove 411 and the guide block 421 that cooperate with each other. When the sliding seat 420 moves to the top working position of the guiding groove 411, the sliding seat 420 stops moving and the top works The position refers to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com