Short pipe fixed-length discharging device and pipeline fixed-length machining system with device

A fixed-length processing and fixed-length technology, which is used in pipe cutting devices, shearing devices, metal processing equipment, etc., can solve the problems of increasing the size deviation of fixed-length pipe fittings, large-size deviation of fixed-length pipes, and unsmooth cutting. , to achieve the effect of improving accuracy and reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

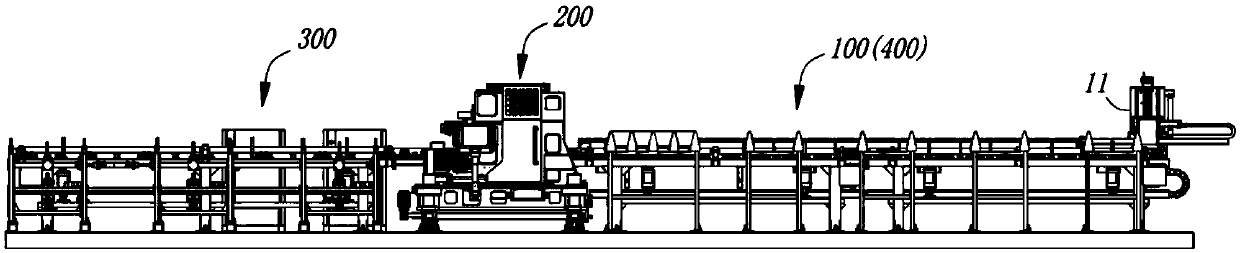

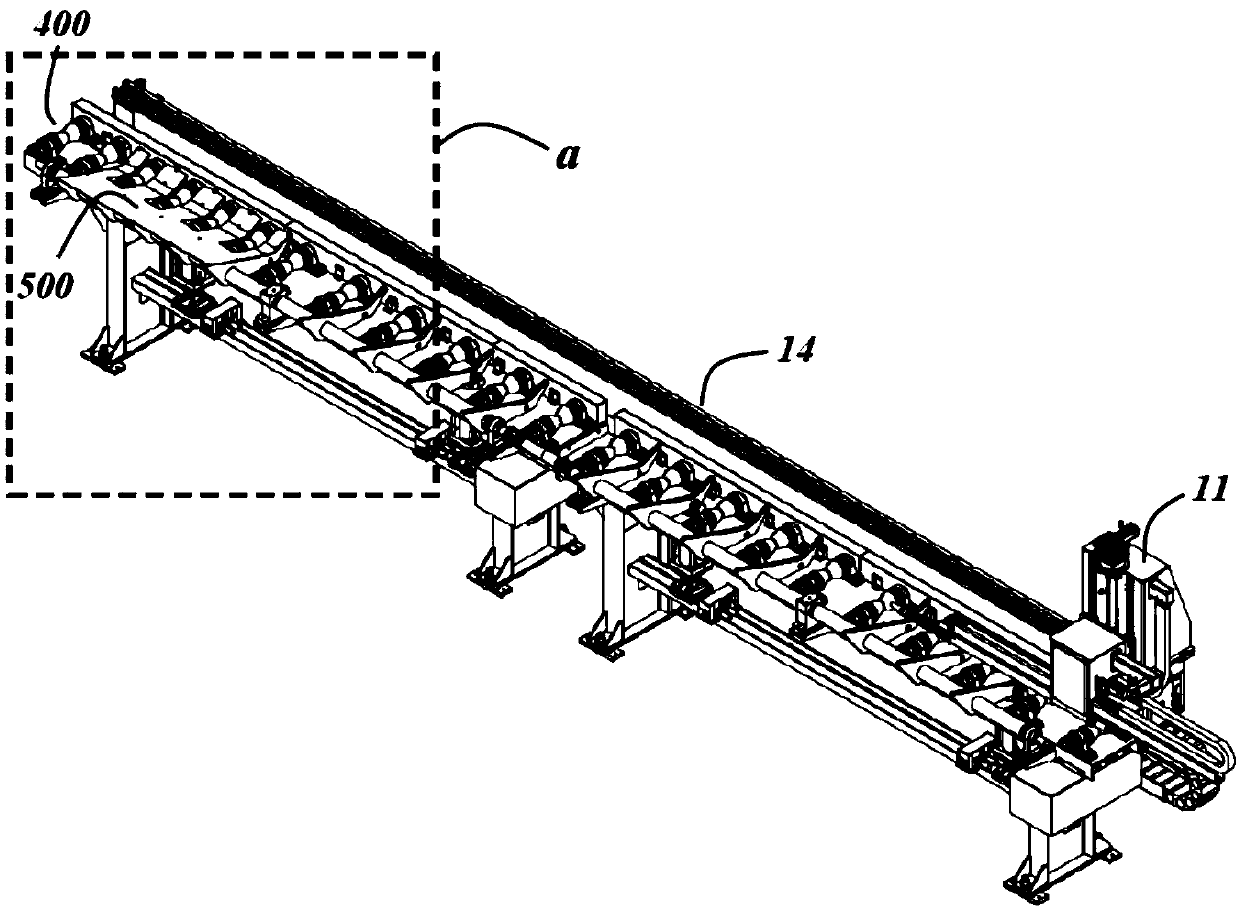

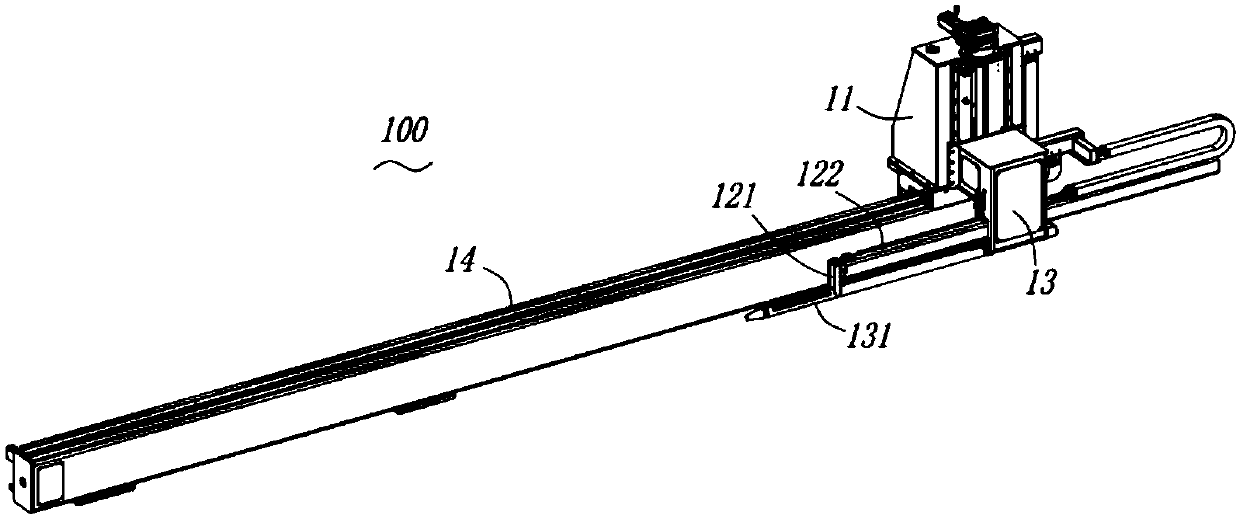

[0030] The present invention will be described in detail below in conjunction with each implementation structure shown in the accompanying drawings, please refer to Figure 1 to Figure 13 As shown, it is some preferred implementation structures of the present invention.

[0031] refer to figure 1 As shown, the short tube fixed-length blanking device 100 involved in the present invention is arranged on one side of the discharge end of the cutting device 200; Figure 7 As shown, in the process of cutting the raw pipe 600 into short pipes 60 by the cutting device 200 , the short pipe fixed-length cutting device 100 is used to define the cutting length of the short pipe 60 and transfer the cut short pipe 60 .

[0032] What needs to be added here is that, for those skilled in the art, it is relatively easy to understand that, during the processing of the original pipe 600 of the present invention, the original pipe 600 is sent to the cutting device 200 along its own length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com