One-step preparation method of zirconium sodium phosphate glass ceramic solidified base material

A technology of sodium zirconium phosphate and glass ceramics, which is applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve problems such as insufficient simplicity, cumbersome equipment requirements, unfavorable crystal phase and composition control, etc., and achieve excellent stability, Excellent chemistry, high inclusion capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A one-step preparation method for a sodium zirconium phosphate glass-ceramic solidified substrate, the steps are:

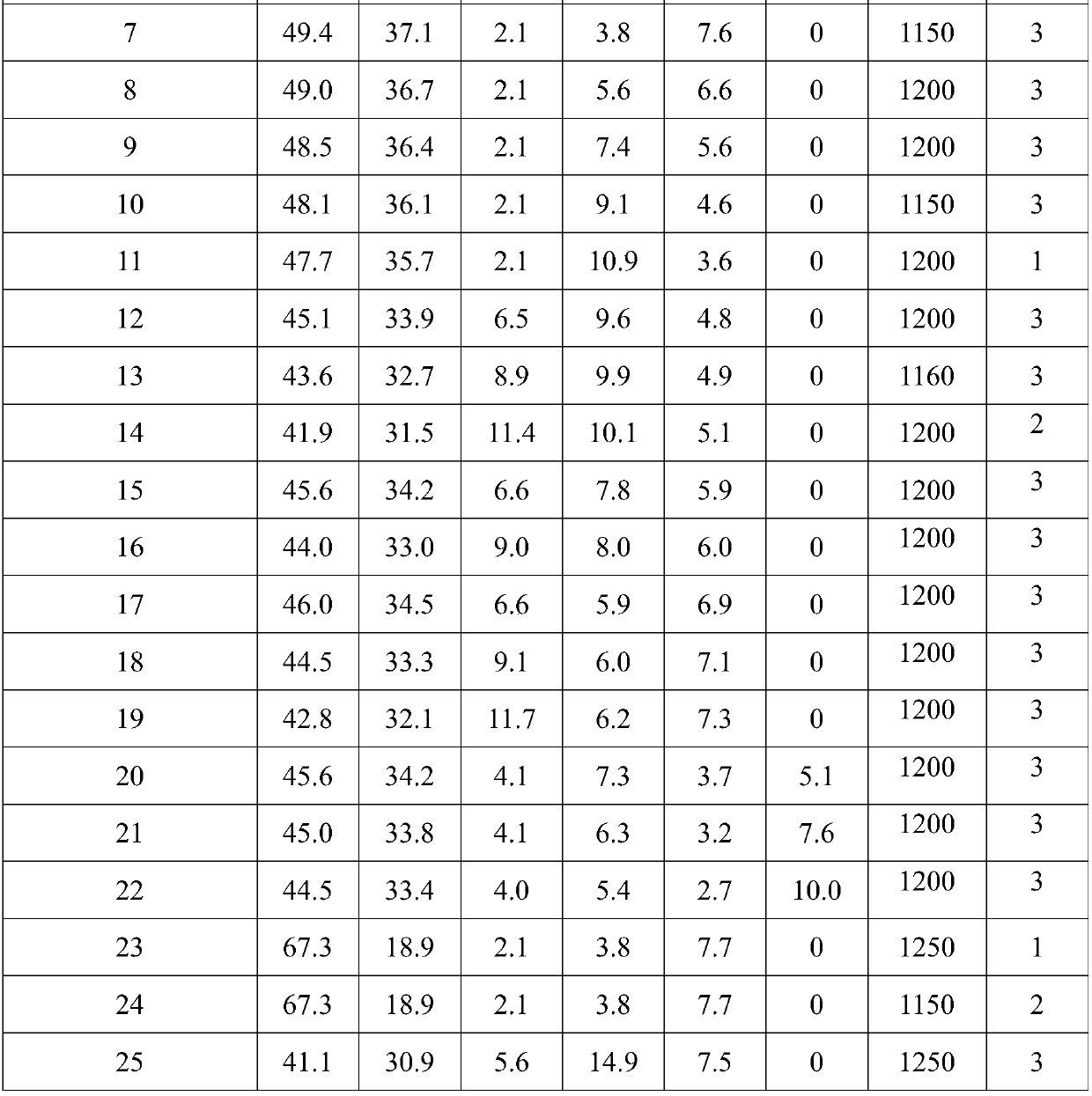

[0036] (1) Ingredients: with P 2 o 5 , Fe 2 o 3 , B 2 o 3 , ZrO 2 、Na 2 O is raw material, press P 2 o 5 49.4 parts by weight, Fe 2 o 3 37.1 parts by weight, B 2 o 3 2.1 parts by weight, ZrO 2 3.8 parts by weight, Na 2 The proportioning of 0.7.6 parts by weight gets each raw material;

[0037] (2) Mixing: put each raw material into a beaker and fully stir and mix evenly to obtain batch materials;

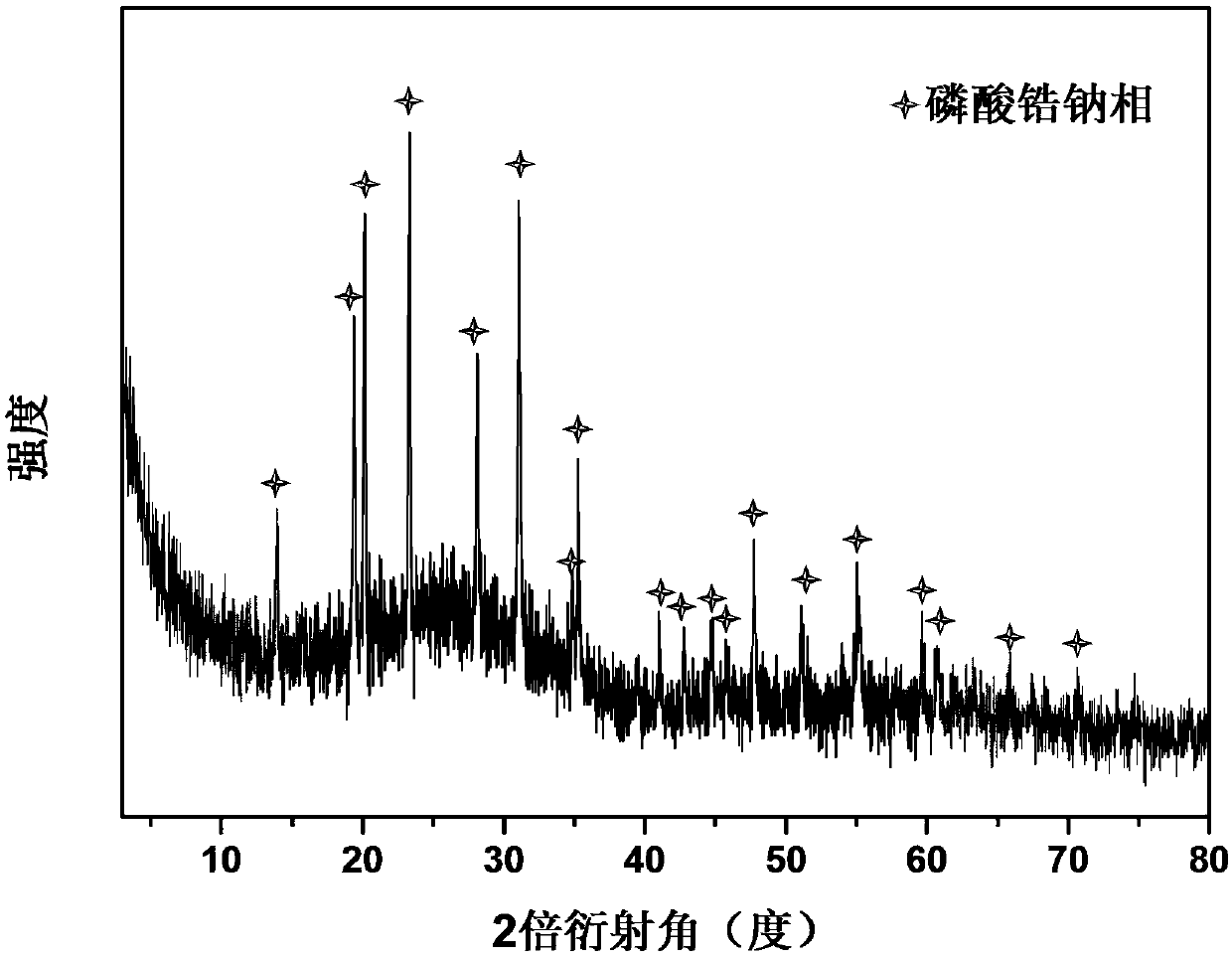

[0038] (3) heat preservation: heat the batch material at a heating rate of 5°C / min to 1200°C for 3 hours to obtain a mixture of glass melt and sodium zirconium phosphate microcrystalline phase;

[0039] (4) Molding: pouring the mixture of the glass melt and sodium zirconium phosphate microcrystalline phase obtained by heat preservation into a preheated mold to form a molded object;

[0040] (5) Annealing: heat the molding at a temperature of...

Embodiment 2

[0042] A one-step preparation method for a sodium zirconium phosphate glass-ceramic solidified substrate, the steps are:

[0043] (1) Ingredients: with P 2 o 5 , Fe 2 o 3 , B 2 o 3 , ZrO 2 、Na 2 O is raw material, press P 2 o 5 45.9 parts by weight, Fe 2 o 3 34.4 parts by weight, B 2 o 3 5.4 parts by weight, ZrO 2 9.5 parts by weight, Na 2 The proportioning of 0.4.8 parts by weight gets each raw material;

[0044] (2) Mixing: put each raw material into the ball milling equipment and fully ball mill and mix evenly to obtain batch materials;

[0045] (3) heat preservation: heat the batch material at a heating rate of 5°C / min to 1200°C for 3 hours to obtain a mixture of glass melt and sodium zirconium phosphate microcrystalline phase;

[0046] (4) Molding: pouring the mixture of the glass melt and sodium zirconium phosphate microcrystalline phase obtained by heat preservation into a preheated mold to form a molded object;

[0047] (5) Annealing: heat the mold...

Embodiment 3

[0049] A one-step preparation method for a sodium zirconium phosphate glass-ceramic solidified substrate, the steps are:

[0050] (1) Ingredients: with P 2 o 5 , Fe 2 o 3 , B 2 o 3 , ZrO 2 、Na 2 O is raw material, press P 2 o 5 46.4 parts by weight, Fe 2 o 3 34.8 parts by weight, B 2 o 3 5.4 parts by weight, ZrO 2 7.7 parts by weight, Na 2 The proportioning of 0.5 parts by weight gets each raw material;

[0051] Others are the same as embodiment 1 or 2, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com