Backwashable and multi-setting packer

A backwash well and packer technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problem of insufficient pressure resistance and temperature resistance, poor sealing time of packers, occurrence of To avoid problems such as hidden dangers in operation, to achieve the effect of excellent performance, complete functions and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

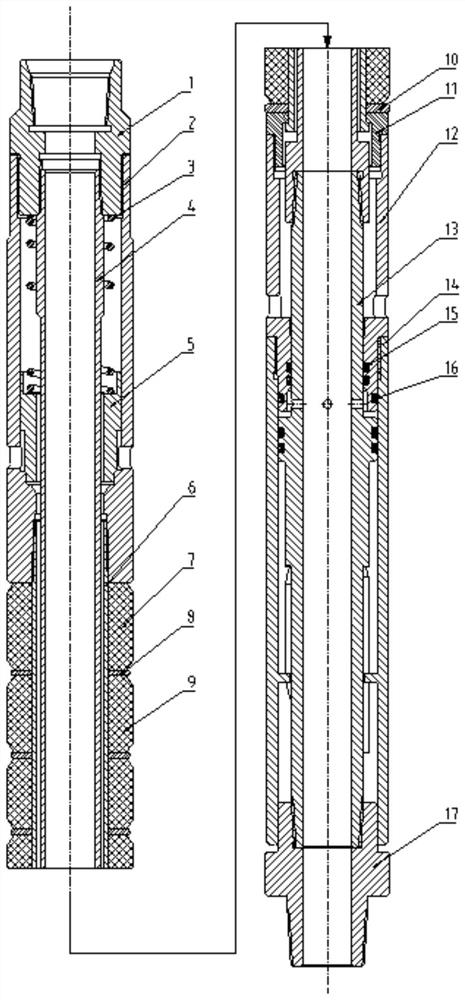

[0017] The present invention will be further described below in conjunction with accompanying drawing:

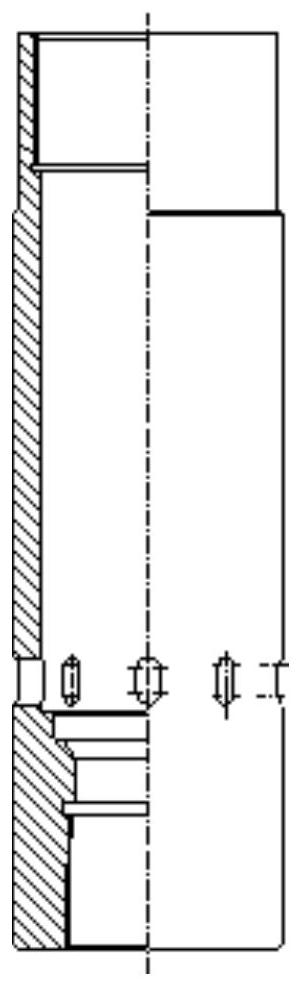

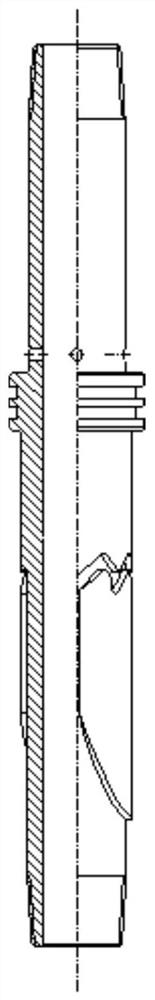

[0018] As shown in the attached figure, the packer that can backwash the well and can be set multiple times is composed of the upper joint 1, the reverse circulation valve outer cylinder 2, the spring 3, the center pipe a4, the piston 5, the rubber cylinder shaft 6, the rubber cylinder a7, rubber cartridge spacer ring 8, rubber cartridge b9, rubber cartridge retaining ring 10, rubber cartridge limit sleeve 11, sleeve a12, central tube b13, sleeve b14, sealing ring a15, sealing ring b16, lower joint 17, Its characteristics are: the assembly sequence is first to put the rubber cartridge limit sleeve 11, the rubber cartridge retaining ring 10, the rubber cartridge a7, the rubber cartridge spacer ring 8, the rubber cartridge b9, the rubber cartridge spacer ring 8, the rubber cartridge b9, the rubber cartridge spacer ring 8. Put the rubber tube a7 into the rubber tube shaft 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com