Electrostatic purification device and range hood provided with same

A purification device and electrostatic technology, applied in the field of range hoods, can solve problems such as failure of electrostatic purification device, failure to work, easy conduction of positive and negative plates, etc., to achieve a simple installation structure, reduce oil fume emissions, and maintain long-term cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

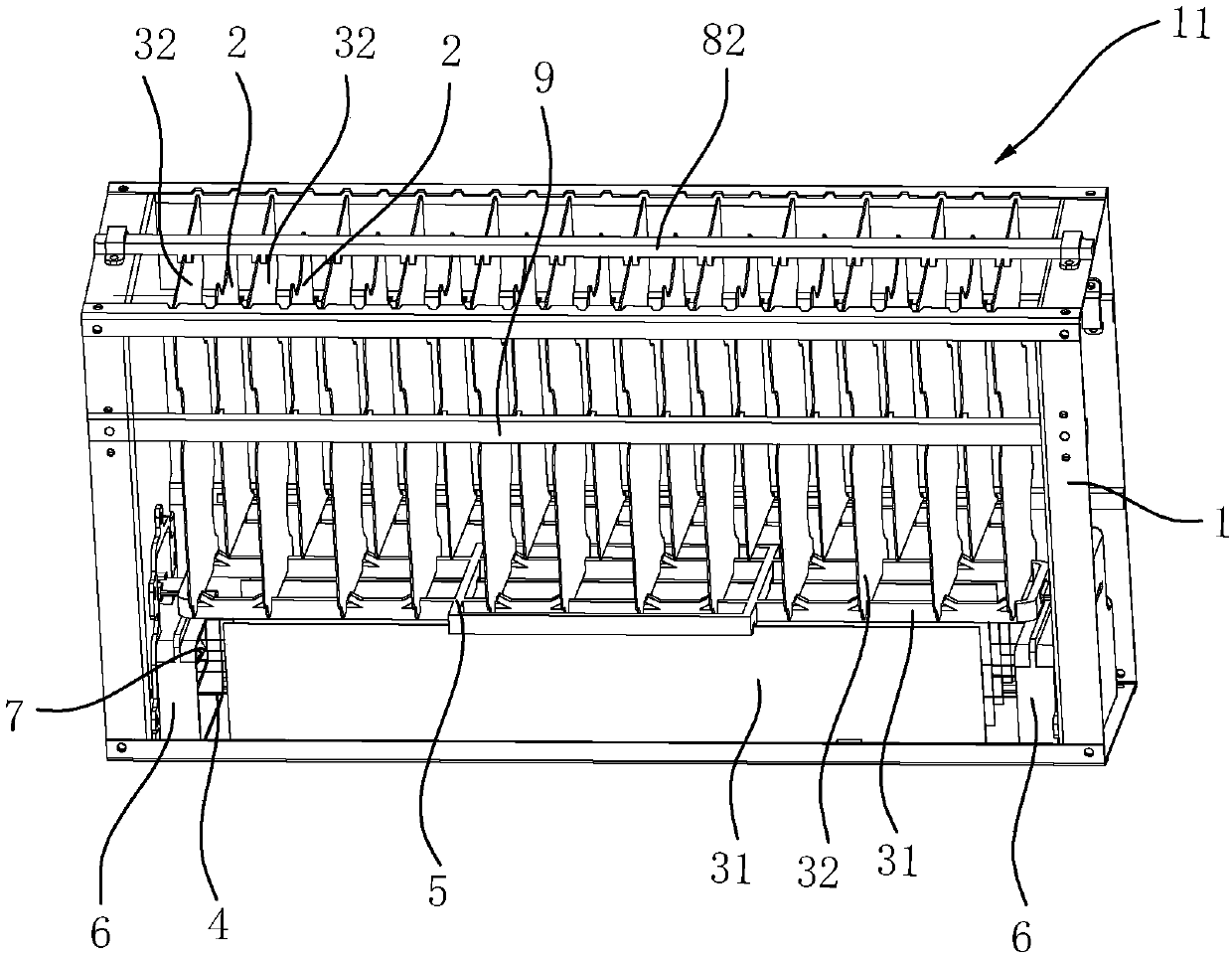

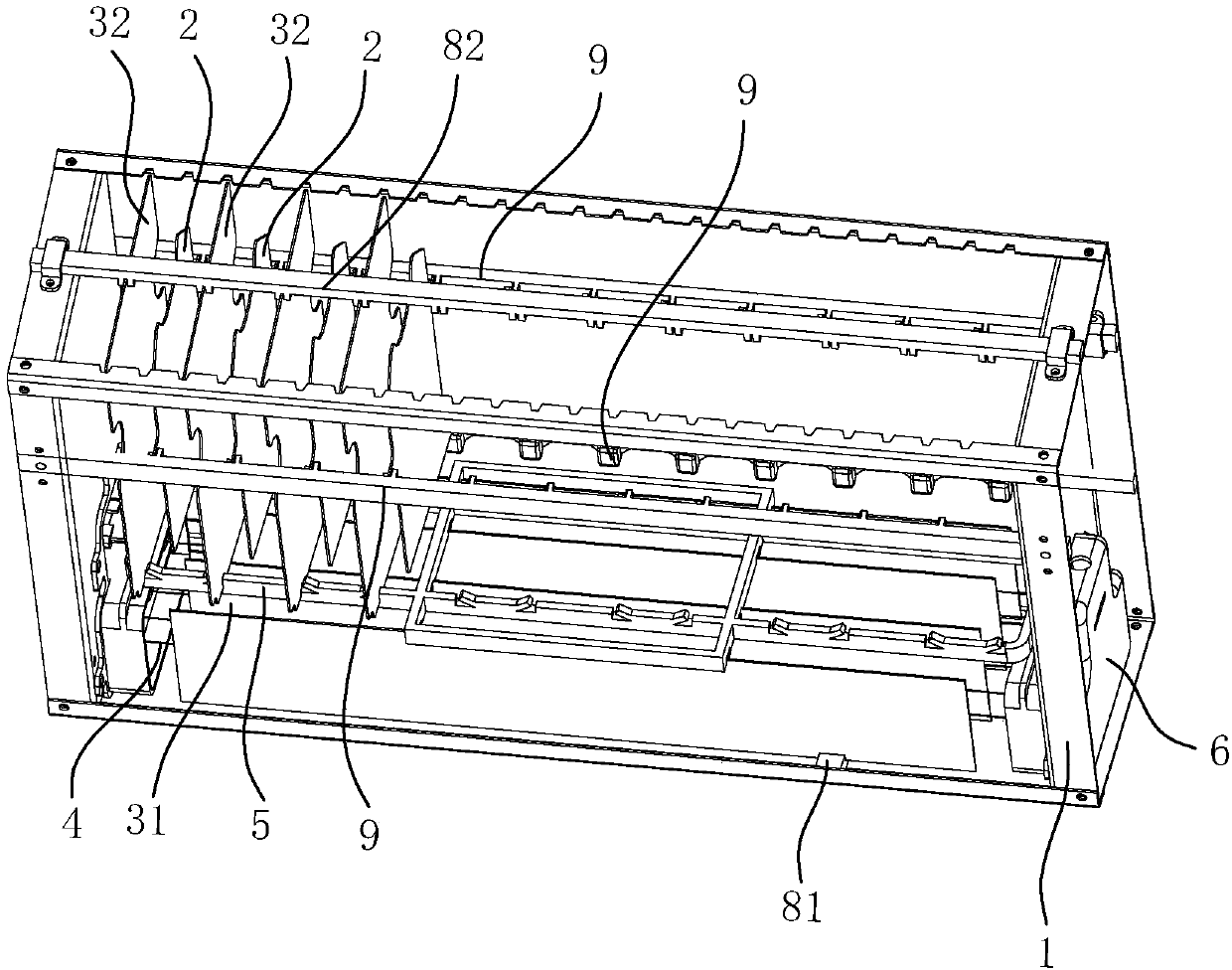

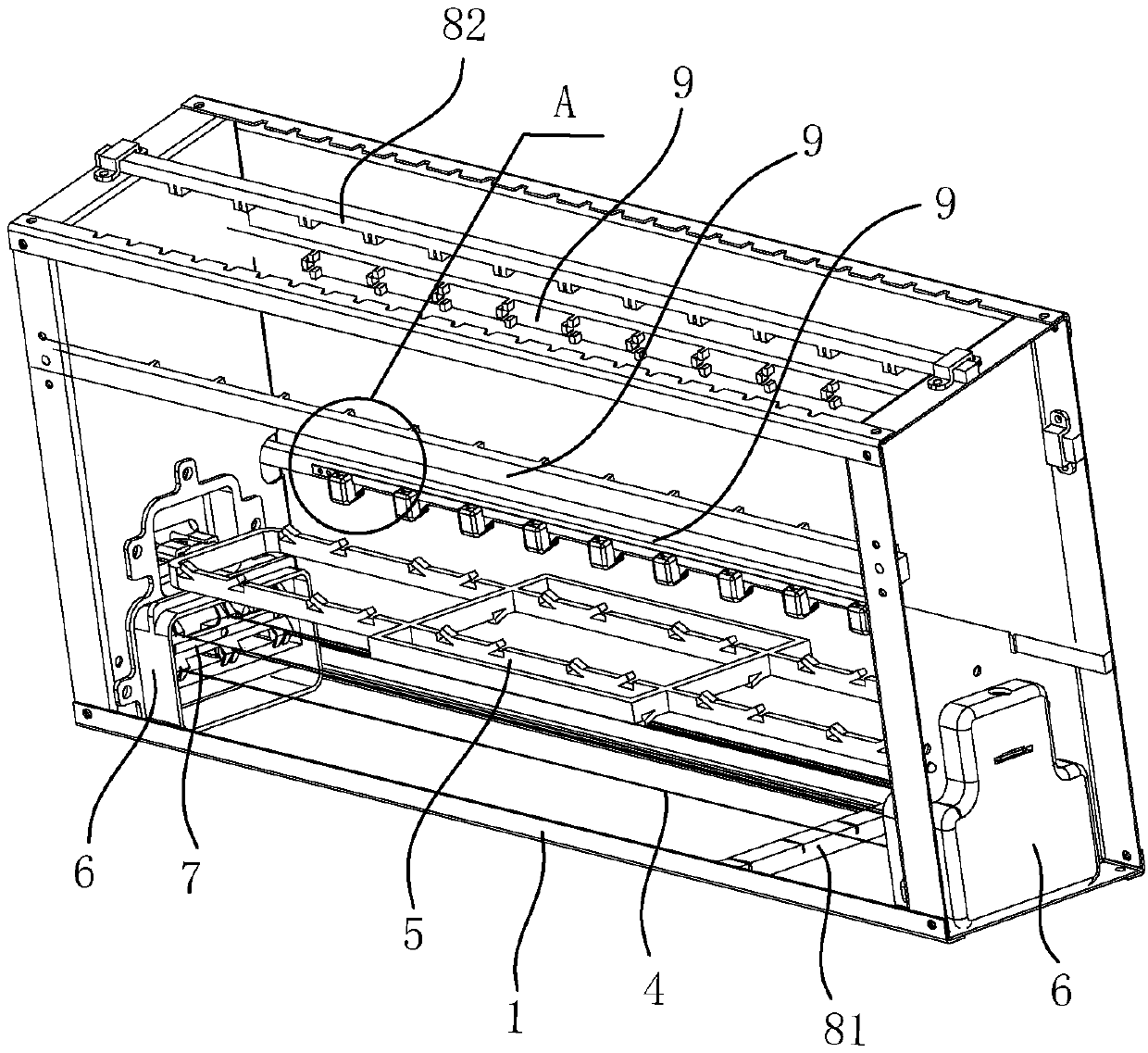

[0024] Such as Figure 1 to Figure 4 As shown, the electrostatic purification device 11 in this embodiment has a rectangular shape as a whole, which specifically includes an outer frame 1, a positive electrode plate 2, a first negative electrode plate 31, a second negative electrode plate 32, an electrode wire 4, an electrode plate connection frame 5, etc. Components. Among them, the positive plate 2 and the first negative plate 31 and the second negative plate 32 are provided inside the outer frame 1, and the first negative plate 31, the second negative plate 32 and the positive plate 2 are all provided with an outer frame for avoiding 1 gap. The electrode plate connection frame 5 is located inside the outer frame 1 and divides the inside of the outer frame into an upper space and a lower space. The first negative electrode plate 31 and the second negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com