OLED display panel and OLED display device

A technology of display panel and concave surface, applied in the field of OLED display panel and OLED display device, can solve the problems of large thickness of polarizer and high reflected light, and achieve the effects of reducing reflectivity, improving contrast, and increasing incident angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Please refer to the drawings in the drawings, in which the same component symbols represent the same components. The following description is based on the exemplified specific embodiments of the application, which should not be construed as limiting other specific embodiments that are not described in detail herein.

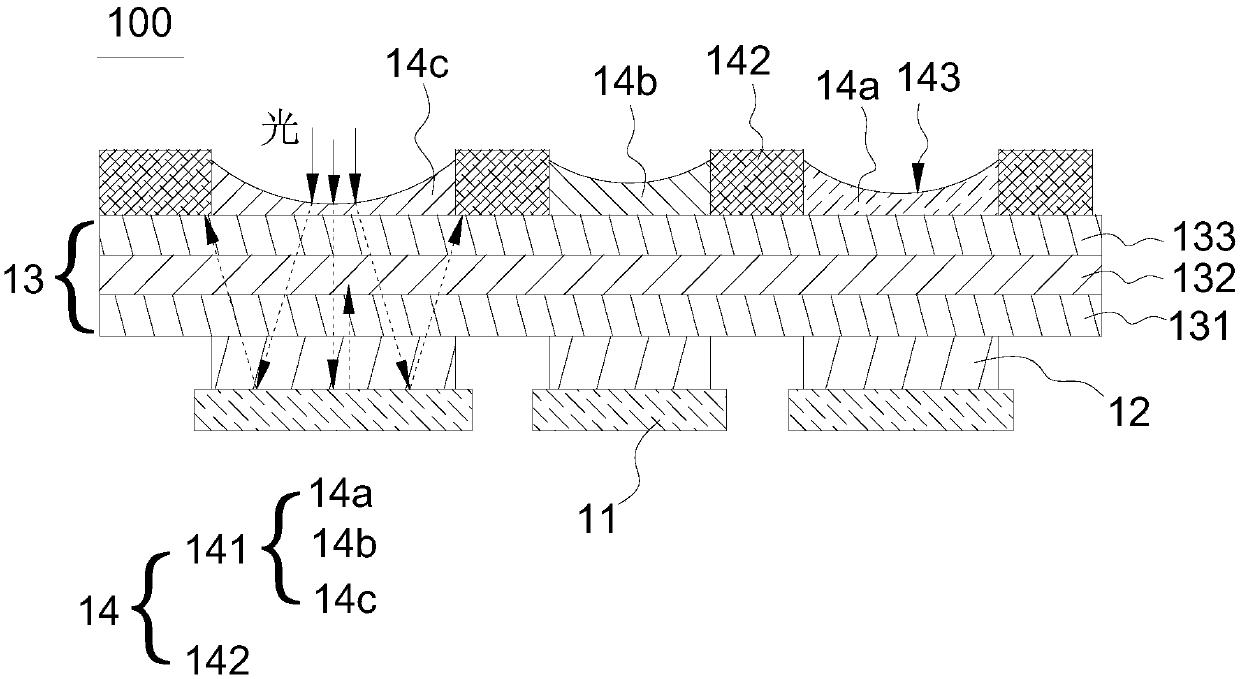

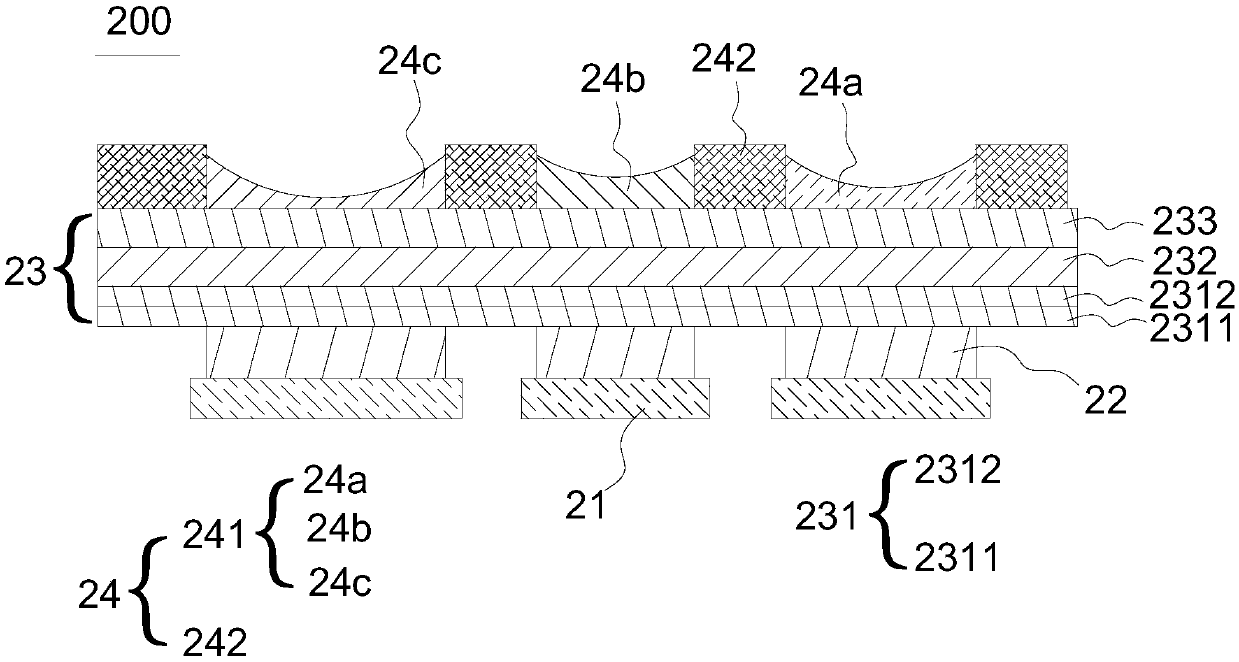

[0037] Please refer to figure 1 , figure 1 This is a schematic structural diagram of the first embodiment of the OLED display panel of this application. The OLED display panel 100 of the first embodiment includes an anode 11, an organic light-emitting layer 12, an encapsulation structure layer 13, and a color filter structure layer 14.

[0038] The organic light emitting layer 12 is provided on the anode 11. The encapsulation structure layer 13 is disposed on the organic light emitting layer 12. The color filter structure layer 14 is disposed on the packaging structure layer 13.

[0039] The color filter structure layer 14 includes a plurality of color resist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com