Nickel-gold plated treatment process for blind hole surface of circuit board

A treatment process, nickel-gold electroplating technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of blind hole electroplating, the solution can not be fully poured, blind hole solution exchange is difficult, etc., to achieve increased Exchange efficiency, improve the plating quality of blind holes, and improve the effect of plating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Prepare a circuit board with metallized blind holes on the surface; here, the size of the blind holes is: the depth of the blind hole is 1.00mm, and the diameter of the blind hole is 0.25mm.

[0023] Step 2: Treat the surface of the metallized blind hole by washing with water.

[0024] Step 3: Before nickel-gold electroplating, remove the air bubbles in the metallized blind holes by ultrasonic; the ultrasonic time before plating is 10 minutes, and the frequency is 45KHZ.

[0025] Step 4: According to the material of the circuit board, set the current parameter of electroplating, and electroplate nickel gold on the surface of the metallized blind hole; here, the circuit board is made of alumina ceramic plate, so the current parameter of electroplating is 1.4A; The surface of the metallized blind hole is electroplated with nickel and gold. Specifically, the electroplating tank is filled with electroplating solution, the circuit board is immersed in the electroplat...

Embodiment 2

[0029] The current parameters of the electroplating were changed to 1.5A; the angle of the swinging motion was changed to 30°. All the other conditions are the same as in Example 1.

Embodiment 3

[0031] The current parameters for electroplating were changed to 1.6A; the angle of the swinging motion was changed to 20°. All the other conditions are the same as in Example 1.

[0032] In this embodiment: the electroplating result is specifically that the plating layer in the metallized blind hole is complete, and the bonding force of the plating layer is qualified.

[0033] In addition to this, a control group is also provided here:

[0034] Control group one:

[0035] Before nickel-gold plating, ultrasonic treatment is not used, that is, step 2 is removed, and the rest is the same as in embodiment 1.

[0036] Control group two:

[0037] Before nickel-gold plating, dithering treatment is not used, that is, step five is removed, and the rest is the same as in embodiment one.

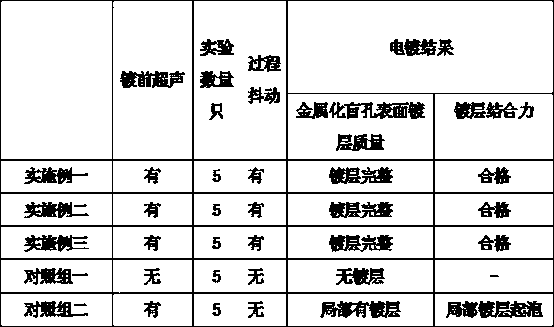

[0038] The electroplating result of each embodiment and control group participates in Table 1:

[0039]

[0040] Table 1

[0041] Comparing the electroplating results of Example 1 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com