Safety helmet

A helmet and main body technology, applied in the field of helmets and helmet production equipment, can solve the problems of heavy metal material, easy to produce concussion, poor cushioning effect, etc., to increase impact resistance, strong practicability, and reduce impact Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

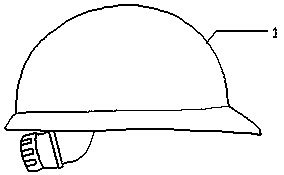

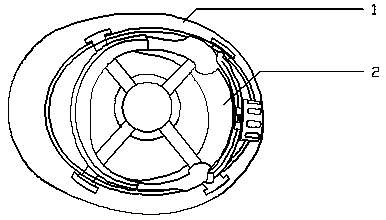

[0044] The safety helmet of this embodiment includes a safety helmet body, a head support is arranged inside the safety helmet body, and a fixing belt is arranged at the bottom of the safety helmet. The safety helmet body includes a shell 1 and an interlayer, and the interlayer is located inside the shell 1 . By changing the structural form of the main body of the helmet including the shell 1 and the interlayer, the original single-layer structure is changed into a double-layer structure, which increases the impact resistance of the helmet, and the helmet is made of hard plastic.

[0045] The interlayer and the shell of the safety helmet can be set in one piece, or can be set as a detachable connection between the two. When it is a detachable connection, a buffer gap is reserved at the connection. Further, a buffer gap is provided in the buffer gap. The cotton layer, on the one hand, increases the cushioning effect, and on the other hand, seals the gaps to prevent dust from ent...

Embodiment 2

[0061] The structure of the safety helmet of this embodiment is basically the same as that of Embodiment 1, and the difference is that each elastic member 9 includes an upper movable head 9-2-1, a lower movable head 9-2-2, a sliding Pipe 9-2-3 and the first spring 9-2-4, upper movable head 9-2-1 and lower movable head 9-2-2 are respectively positioned at the upper and lower ends of the slide pipe 9-2-3. The upper and lower ends of 9-2-3 are provided with constrictions, the middle part of the upper movable head 9-2-1 has an annular step, and the positioning head 9-2-5 is connected to the lower part of the annular step, and the root of the positioning head 9-2-5 is set There is a rubber ring, the upper part of the lower movable head 9-2-2 has a top 9-2-6, and a cylindrical cavity for the positioning head to be inserted is arranged inside the top 9-2-6, and the first spring 9-2-4 is set in the cylindrical cavity.

[0062] By arranging the elastic member into a structural form in...

Embodiment 3

[0064] The structure of the safety helmet of this embodiment is basically the same as that of Embodiment 1, the difference being that: an epp fireproof foam layer 13 is arranged on the lower surface of the inner shell 2, and a sweat-absorbing layer 14 is arranged on the surface of the epp fireproof foam layer 13. The epp fireproof foam layer 13 is located on the inner surface of the inner shell. It has the characteristics of light weight and soft fireproof contact. Contact causes trauma. The sweat-absorbing layer can absorb moisture and sweat to keep the inside of the cap dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com