High-precision positioning center

A high-precision, top-notch technology, applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of affecting positioning accuracy, loosening of fixing screws, and reduced positioning accuracy, and achieve high positioning accuracy and positioning accuracy. Reliable, high-precision installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

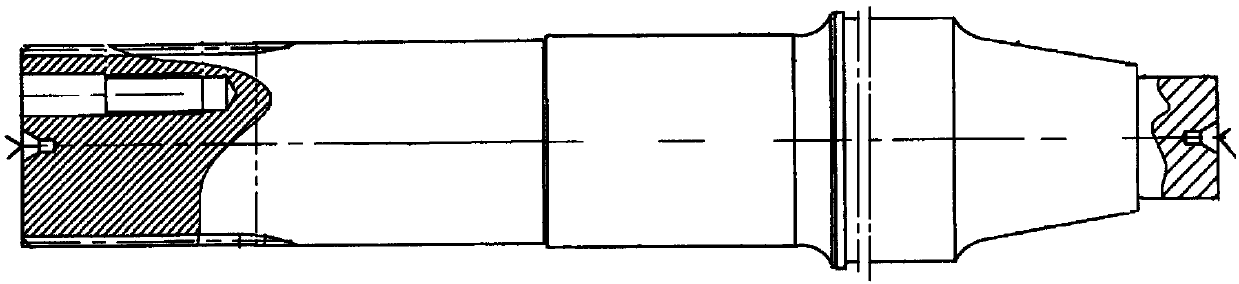

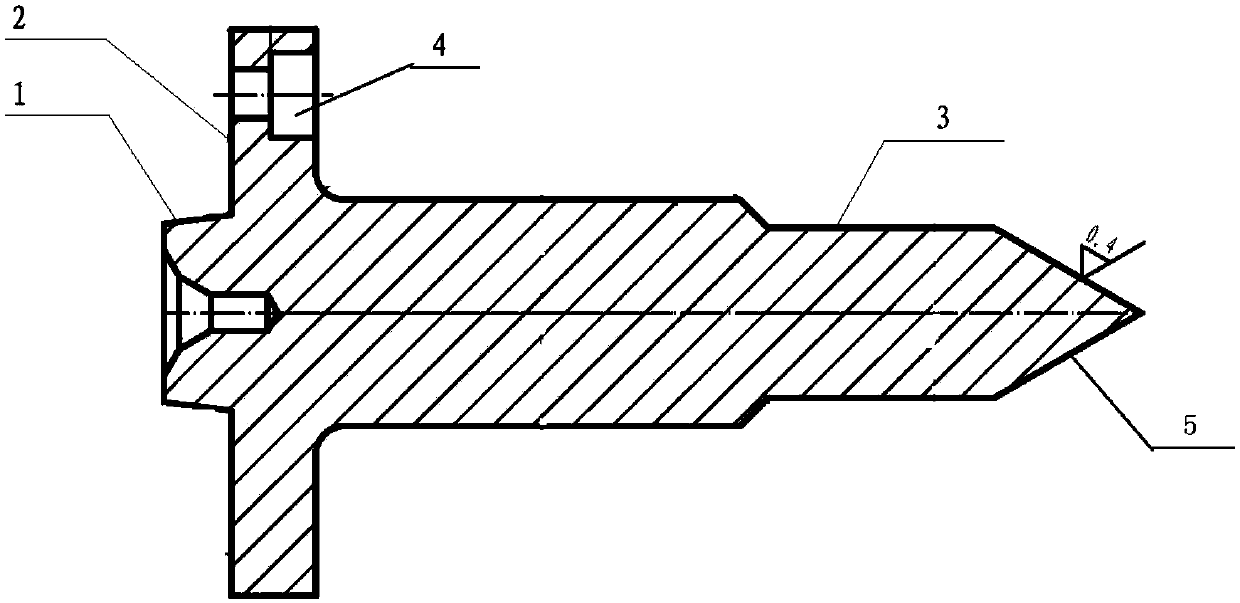

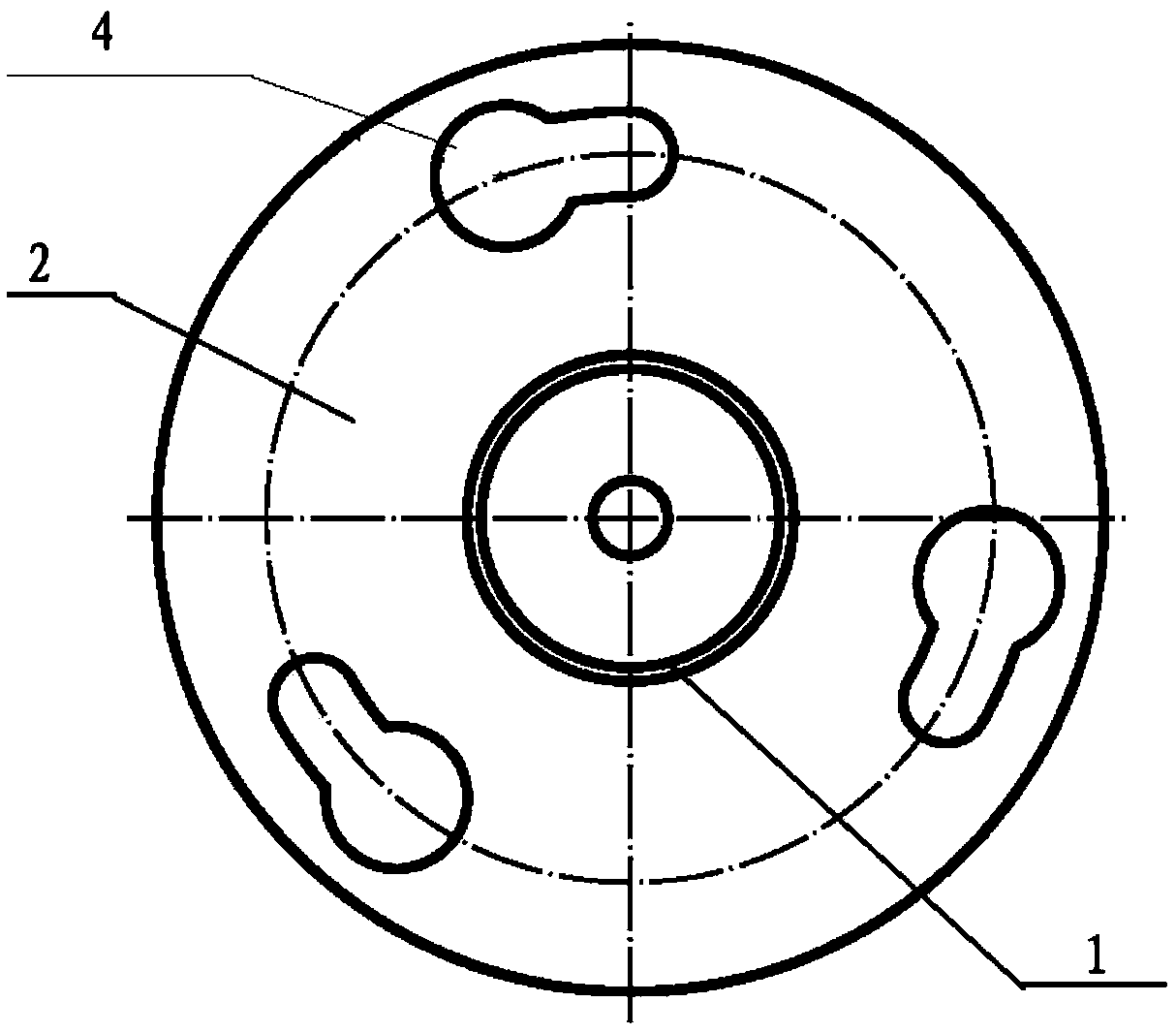

[0018] see figure 2 as well as image 3 , the present invention provides a high-precision positioning top. The high-precision positioning top includes a rear cone 1, a connecting positioning flange and a front cone 5; the rear cone 1 and the front cone 5 are on the same axis; the rear cone 1 is connected to the positioning flange It is connected with the front cone 5; the connecting positioning flange is provided with a top positioning end face 2; the axis of the rear cone is perpendicular to the line surface of the top positioning end face 2. The present invention modifies the traditional rear cone positioning to an over-positioning method in which the rear cone conical surface and the top positioning end face are combined to realize double positioning. Since the connecting and positioning flange is provided with the top positioning end face 2, on the one hand, the top can be repositioned, and on the other hand, the top can be connected with the machine tool to play a stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com