Concrete prefabricate mixing device

A mixing device and pre-product technology, which is applied to clay preparation devices, mixing operation control devices, and sales raw material supply devices, etc., can solve the problems of low batching efficiency and large floor space, and reduce enterprise costs and floor space The effect of small, reduced number of runs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the structure and principle of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

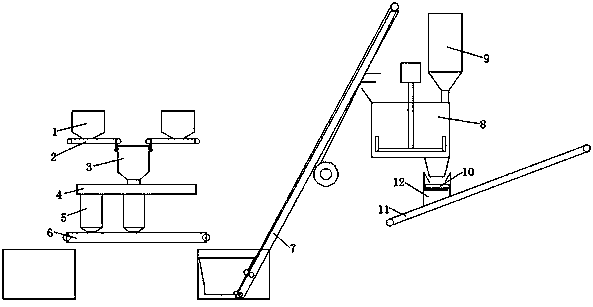

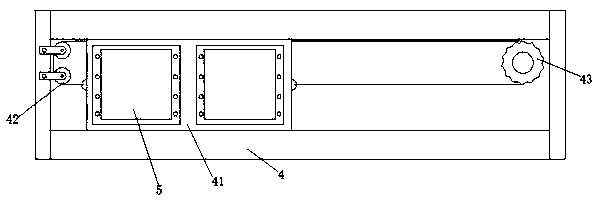

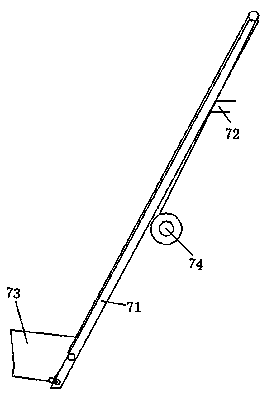

[0021] Such as figure 1 As shown, a concrete pre-product mixing device includes a plurality of storage hoppers-1, a conveyor belt-2 capable of transporting materials in the storage hopper-1 is provided below the storage hopper-1, and the feeding end of the conveyor belt-2 is provided There is a metering hopper 3, a storage hopper 2 5 is arranged under the metering hopper 1 3, and a reciprocating conveyor belt 2 6 is arranged under the storage hopper 2 5, that is, the conveyor belt 2 6 is driven by a positive and negative motor to rotate to two Direction movement conveys material, the bottom of conveyor belt two 6 two ends is respectively provided with elevator 7, and conveyor belt two 6 transports the falling material and enters in elevator 7, and the feeding end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com