Arrangement for sprinkling and pre-washing flue gas in entrance of flue gas-desulfurizing absorption tower

A desulfurization absorption tower and pre-washing technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of convenient construction, easy implementation, and reduced number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

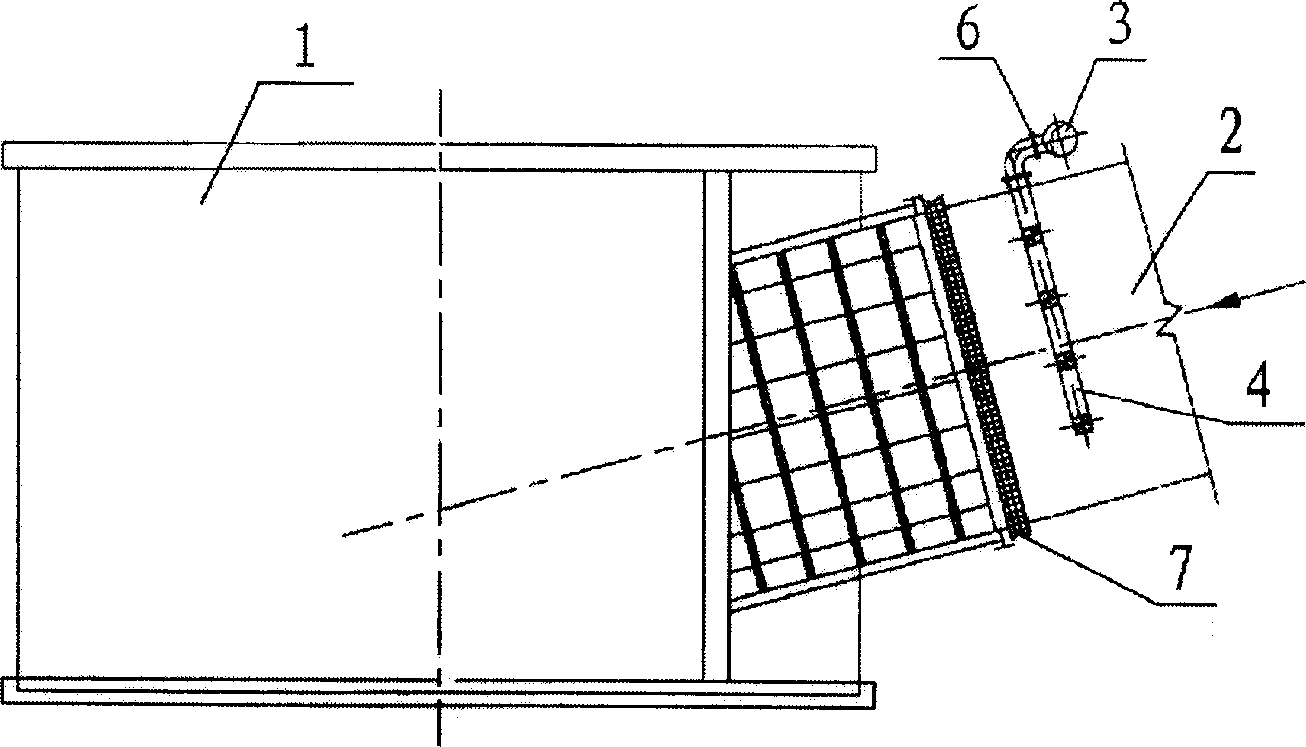

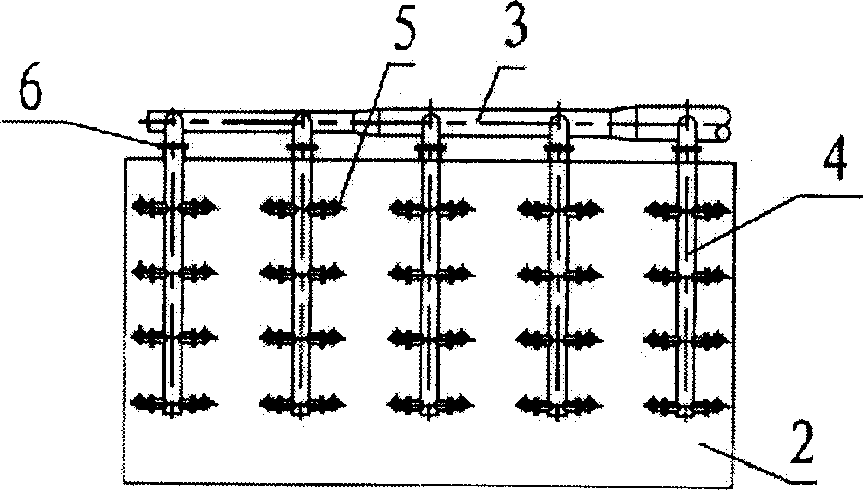

[0020] Examples see figure 1 and 2 The flue gas spray pre-washing device is installed in the flue 2 of the flue gas inlet of the absorption tower 1, and the expansion joint 7 can be arranged on the flue 2. The flue gas spraying pre-washing device is divided into spraying sub-pipes 4 from the spraying main pipe 3, and the spraying sub-pipes are connected to the nozzles 5 at intervals. The spray sub-pipe is perpendicular to the flue gas flow, inserted into the flue from above the flue, and the nozzles are evenly connected to both sides of the spray sub-pipe.

[0021] The spray sub-pipe 4 is flange-connected with the pipe interface 6 connected outside the flue wall. The interval between the spraying sub-pipes is 1-2 meters.

[0022] The diameter of the spray main pipe 3 decreases gradually or in steps along the downstream direction. Spray main pipe 4 is made of 316L stainless steel pipe lined with glass flake layer to prevent the slurry from corroding the pipe.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com