Bottom mold locking device and using method thereof

A locking device and bottom mold technology, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of lower bottom mold replacement efficiency, high assembly technology requirements, and bottom mold pull nails are easy to break, and improve replacement efficiency , Reduce the difficulty of operation, simplify the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

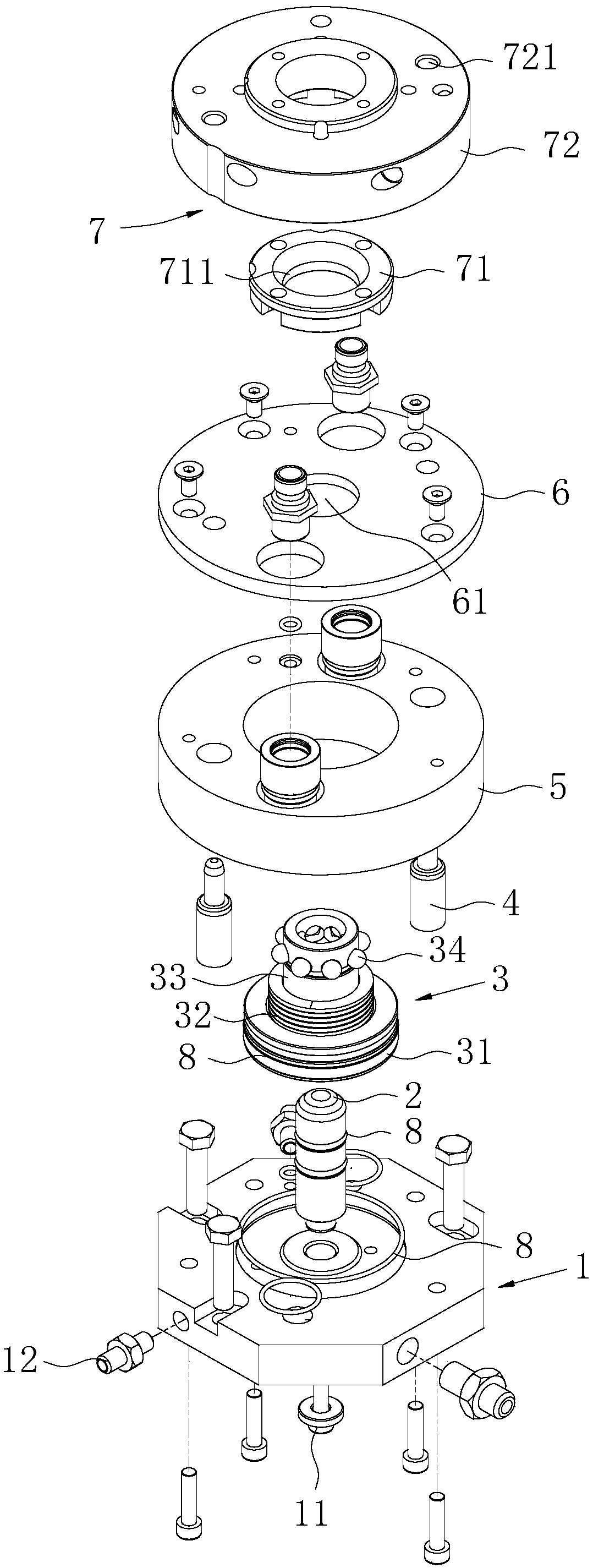

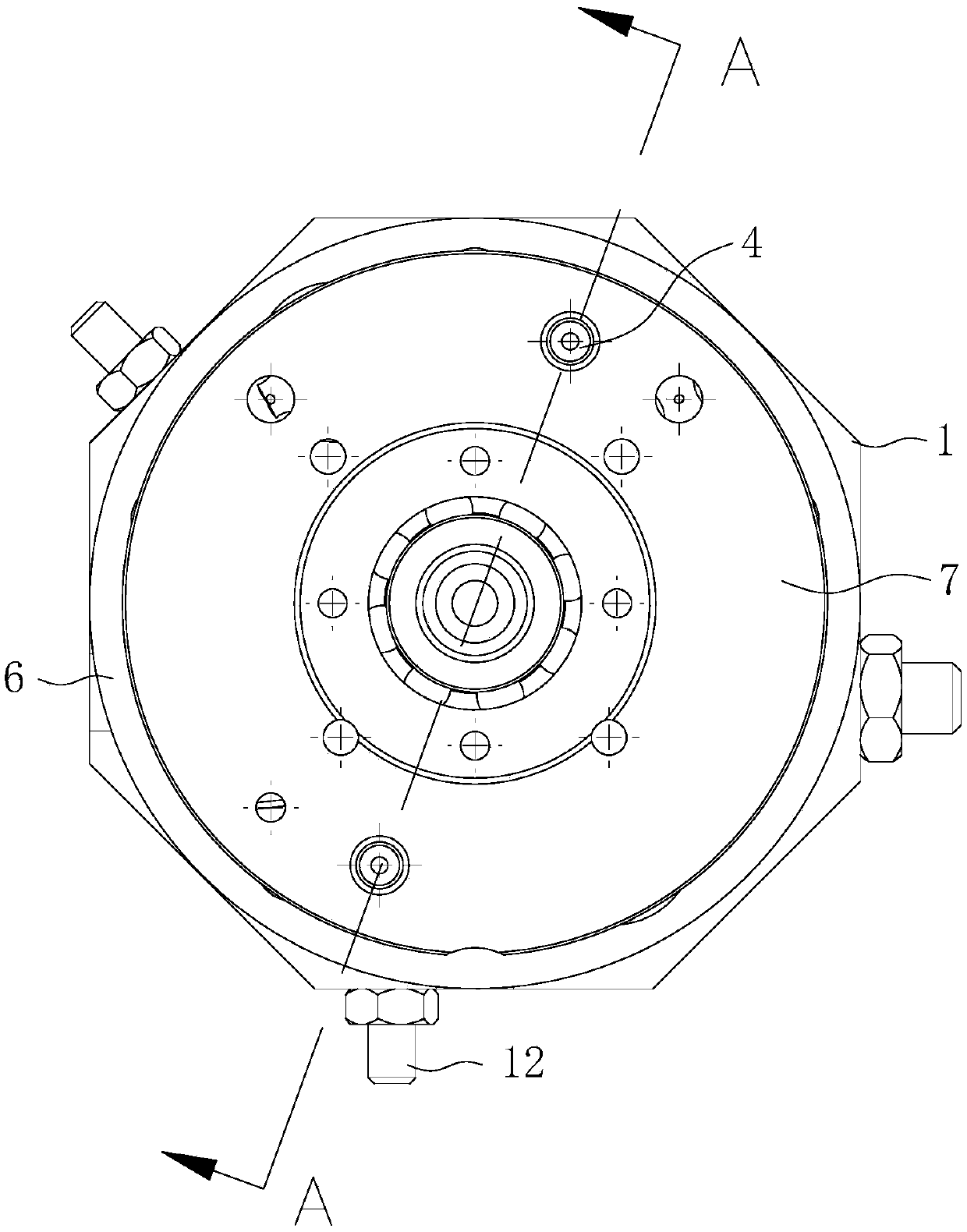

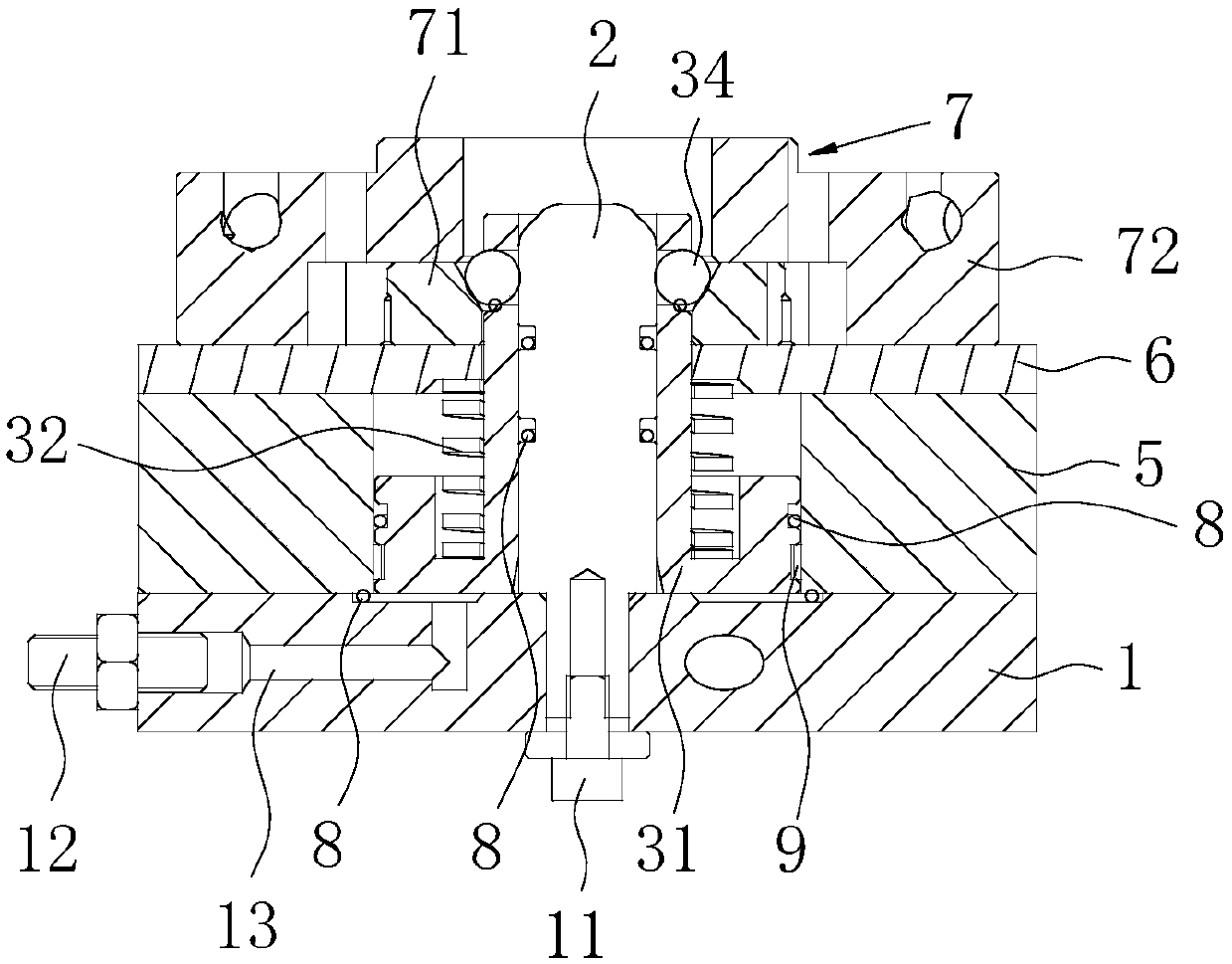

[0035] Such as Figure 1 to Figure 5 As shown, the bottom mold locking device of this embodiment includes a mounting base plate 1 , a positioning column 2 , a locking shaft 3 , a positioning pin shaft 4 , a hollow collar 5 , a cover plate 6 , a bottom mold connecting block 7 and a sealing ring 8 . The positioning column 2 is fixed on the installation base plate 1 by screws 11, the locking shaft 3 is sleeved on the positioning column 2 and can move along the axial direction of the positioning column 2, and the hollow collar 5 is sleeved on the outer periphery of the locking shaft 3 and connected to the installation base plate 1 Connected by screws, the cover plate 6 and the top of the hollow collar 5 are connected by screws, and the bottom mold connection block 7 is positioned on the top of the cover plate 6 through the positioning pin shaft 4 .

[0036] The locking shaft 3 includes a base 31 , a spring 32 , a body 33 and a locking ball 34 .

[0037] In this embodiment, the ba...

Embodiment 2

[0048] Such as image 3 As shown, on the basis of the first embodiment, a guide ring groove is provided on the base 31 of this embodiment, and a guide ring 9 is arranged inside the guide ring groove. By arranging the guide ring 9, on the one hand, the direct friction between the outer wall of the base 31 and the inner wall of the hollow collar 5 can be avoided, thereby prolonging the service life of the device; smooth.

Embodiment 3

[0050] Such as Figure 4 As shown, on the basis of any of the above-mentioned embodiments, the locking shaft 3 of this embodiment further includes a stop ring 35 disposed in the through hole of the body 33 on the side away from the positioning post 2 . The limiting ring 35 is located below the locking ball 34. When the locking ball 34 is in a movable state, the limiting ring 35 prevents the locking ball 34 from leaving the through hole of the body 33 in a direction away from the positioning column 2, preventing the locking ball 34 from falling from the side. fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com