Multi-functional label transferring device for labeling in die

An in-mold labeling and conveying device technology, applied in the field of manufacturing and labeling, can solve the problems of inability to meet the requirements of different cup distances, difficult to adjust the row distance at will, affecting the labeling effect, etc. Running speed, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

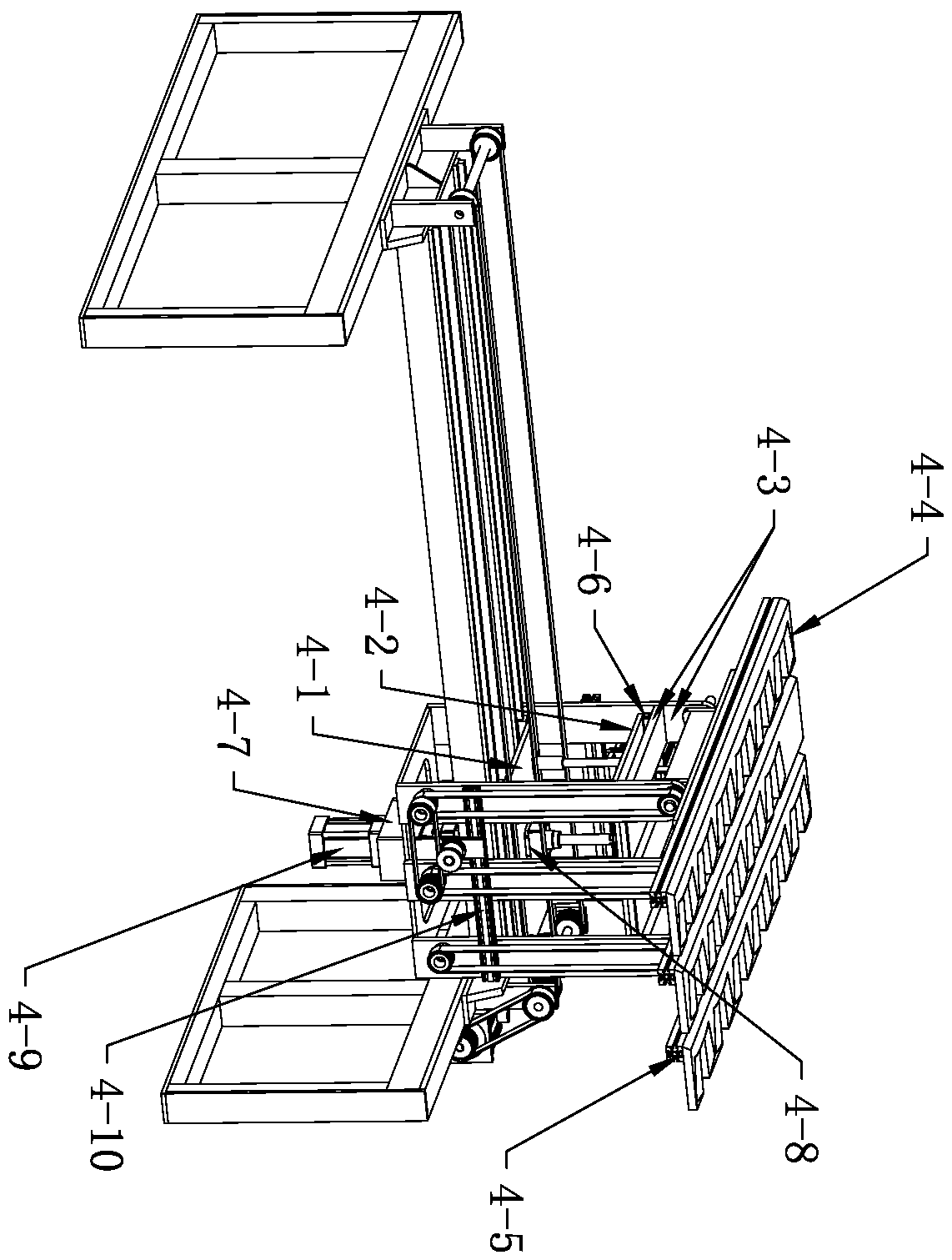

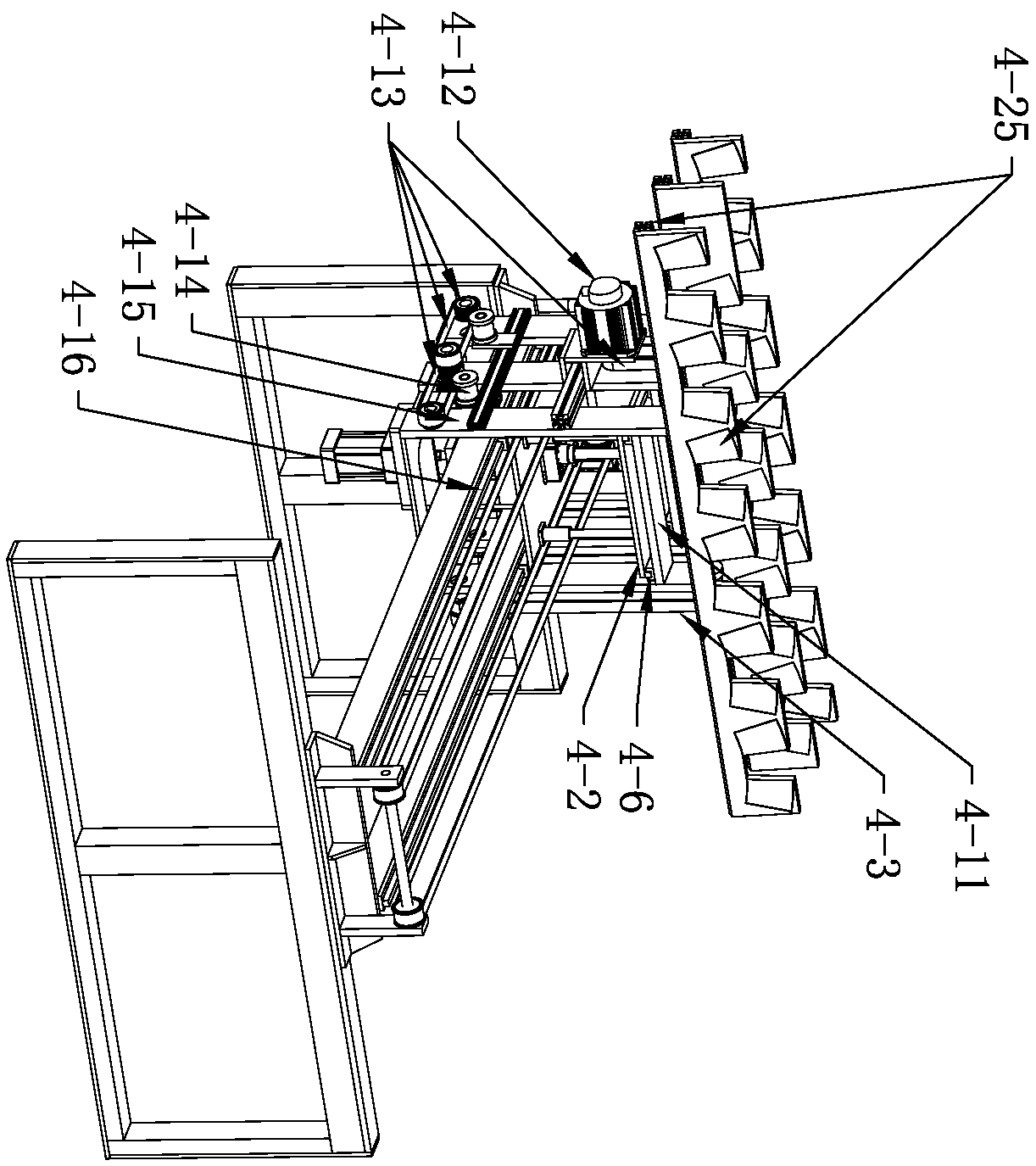

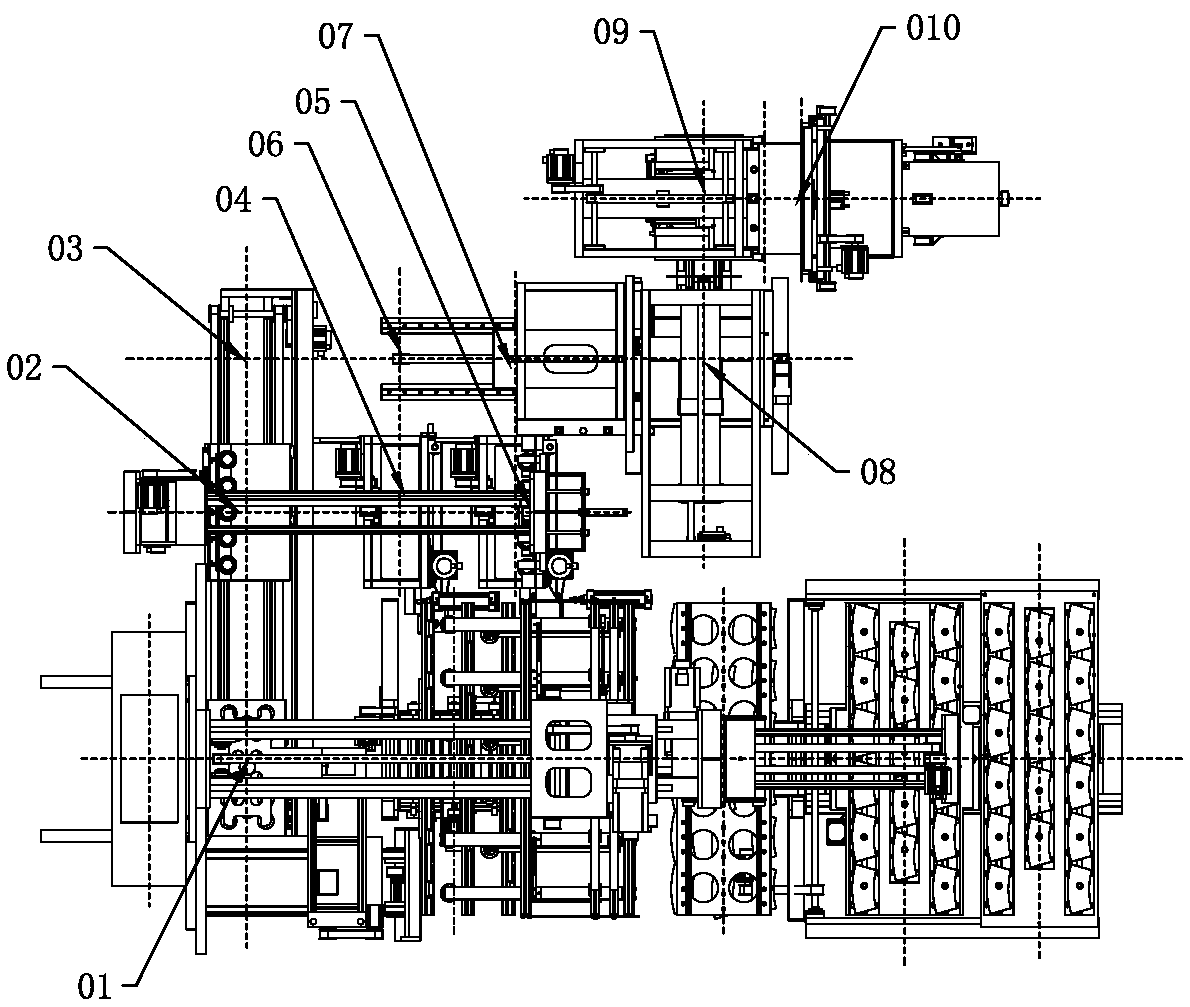

[0051] see Figures 1 to 9 , the multifunctional in-mold labeling label transfer device 4 of this embodiment includes a translation mechanism, an angle rotation mechanism, a lifting mechanism, a translation lifting support base 4-1 and a multi-row label placement unit 4-19. The translation mechanism of this embodiment includes a translation support frame and a translation drive device. The translation support frame passes through the inside of a plurality of single-row support frames 4-3, and translation sliding pairs 4-16 are respectively installed on both sides of the translation support frame. The lifting support base 4-1 is fixedly connected with the sliding portion of the translation sliding pair 4-16 and driven by the translation driving device to move along the translation sliding pair 4-16. In this embodiment, the translation sliding pair 4-16 is a guide rail, and the guide rail is installed on the translation lifting support base 4-1, and the translation driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com