8-aminoquinoline modified starch chelating agent and preparation method thereof

An aminoquinoline, chelating agent technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve low cost, good adsorption, and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

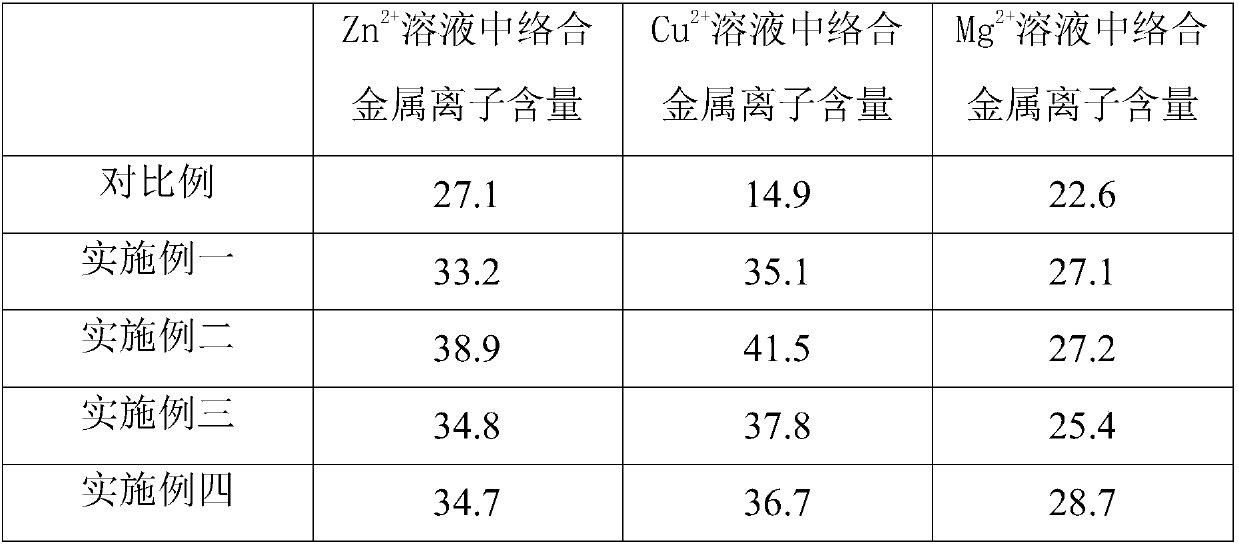

Examples

Embodiment 1

[0022] Present embodiment formula and method are as follows:

[0023] 1. Take 100 parts of tapioca starch and disperse in water, then add 20 parts of sodium periodate, mix well, and react for 2 hours under dark conditions to fully oxidize the starch. Then, the product was washed 3 times with deionized water and 1 time with ethanol.

[0024] 2. Disperse the above product in an appropriate amount of water, add 30 parts of 8-aminoquinoline, adjust the pH of the system to 5 with acid, and react for 3 hours at a temperature of 60-65°C to obtain a crude product.

[0025] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0026] 4. Wash 2 to 3 times with 70% ethanol solution, then put the product into an oven at 45°C to dry, pulverize, and set aside.

Embodiment 2

[0028] Present embodiment formula and method are as follows:

[0029] 1. Take 100 parts of tapioca starch and disperse in water, then add 20 parts of sodium periodate, mix well, and react for 3 hours under dark conditions to fully oxidize the starch. Then, the product was washed 3 times with deionized water and 1 time with ethanol.

[0030] 2. Disperse the above product in an appropriate amount of water, add 55 parts of 8-aminoquinoline, adjust the pH of the system to 5 with acid, and react for 4 hours at a temperature of 60-65°C to obtain a crude product.

[0031] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0032] 4. Wash 2 to 3 times with 70% ethanol solution, then put the product into an oven at 45°C to dry, pulverize, and set aside.

Embodiment 3

[0034] Present embodiment formula and method are as follows:

[0035] 1. Take 100 parts of tapioca starch and disperse in water, then add 50 parts of sodium periodate, mix well, and react for 2 hours under dark conditions to fully oxidize the starch. Then, the product was washed 3 times with deionized water and 1 time with ethanol.

[0036] 2. Disperse the above product in an appropriate amount of water, add 55 parts of 8-aminoquinoline, adjust the pH of the system to 5 with acid, and react for 55 hours at a temperature of 60-65°C to obtain a crude product.

[0037] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0038] 4. Wash 2 to 3 times with 70% ethanol solution, then put the product into an oven at 45°C to dry, pulverize, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com