Double-smelting-position alternate vacuum self-consuming furnace

A vacuum consumable furnace and alternating technology, applied in the field of double melting position alternating vacuum consumable furnace, can solve the problems of poor smelting quality and low smelting efficiency, and achieve the advantages of improving smelting efficiency, obvious cooling effect and improving smelting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

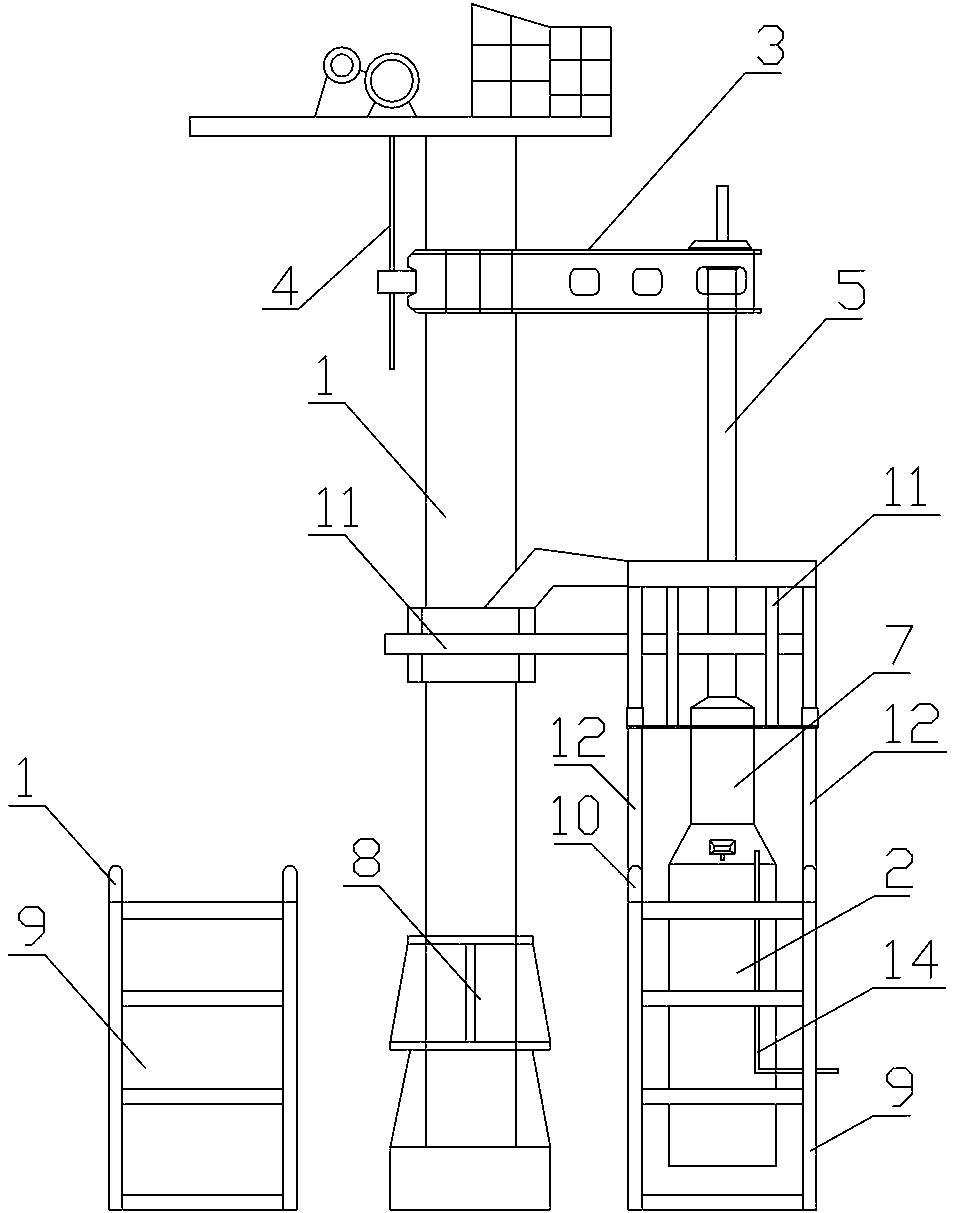

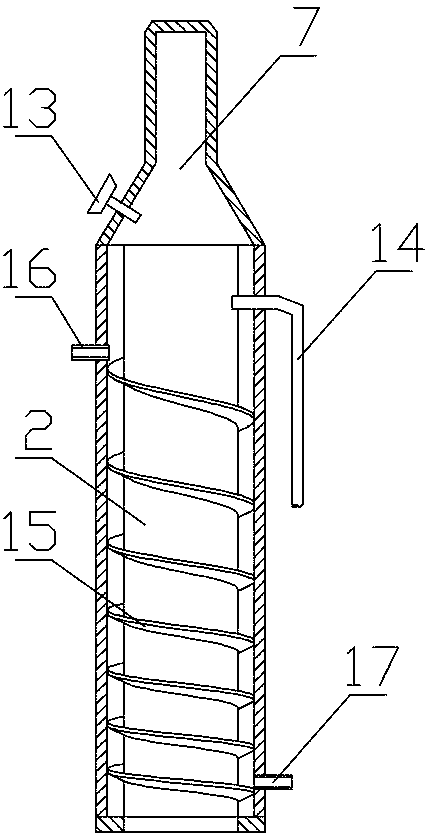

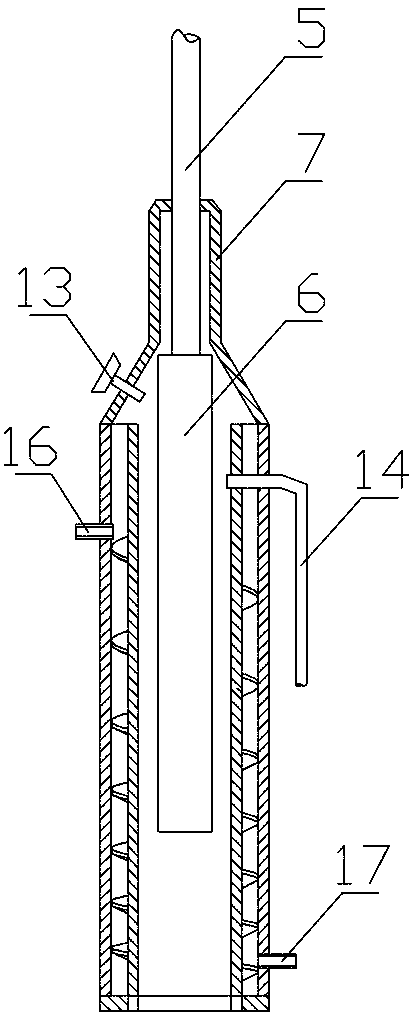

[0017] In this embodiment, a double-melting-position alternating vacuum consumable furnace has a lifting guide frame 1 for adjusting the height of the workpiece and a crystallization furnace 2 for melting the workpiece. The upper end of the lifting guide frame 1 is slidably installed with a The electrode clamping device 3 for lifting and lowering the guide frame 1, a screw lifter 4 is installed at one end of the electrode clamping device 3, and a dummy electrode 5 is clamped at the other end, the self-consumable electrode 6 is welded on the bottom of the dummy electrode 5, and the consumable electrode 6 extends into the inside of the crystallization furnace 2, and a detachable sealing cover 7 is installed between the upper end of the crystallization furnace 2 and the dummy electrode 5.

[0018] In this embodiment, a transposition base 8 that can rotate back and forth between the two melting positions is installed on the bottom of the lifting guide frame 1, and a base for accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com