A multi-axis coordinated high-precision liquid phase pump control method based on online compensation

A control method and technology of liquid phase pump, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve problems such as large pulsation rate, uncompensable offline operating parameters, and poor flow delivery consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

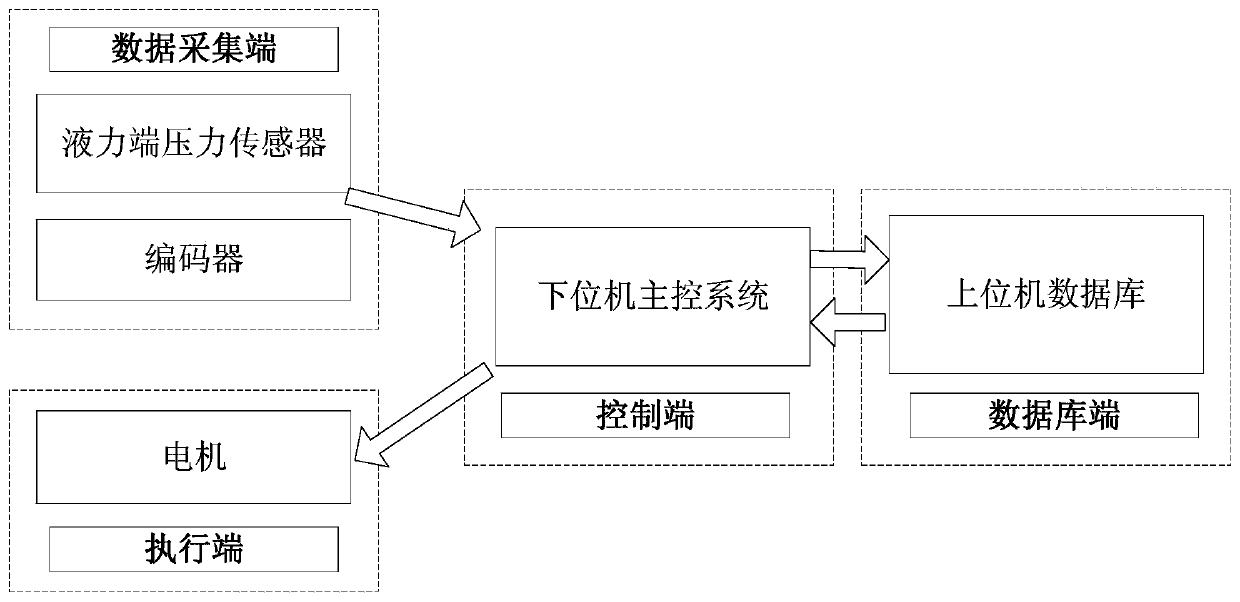

[0048] A multi-axis collaborative high-precision liquid-phase pump control method based on online compensation. By monitoring and calculating the motor speed of the liquid-phase pump in different states, it ensures the coordination of multi-axis control of the liquid-phase pump and the fluid compressibility. Flow compensation and ultra-high pressure sealing, such as figure 1 As shown, the specific contents include:

[0049] (1) Assemble the high-precision ultra-high pressure liquid phase pump

[0050] The high-precision ultra-high pressure liquid phase pump is composed of two independent pump units, called A pump unit and B pump unit, which are respectively composed of two sub-pumps, called A-PRI sub-pump and A-ACC sub-pump respectively. pump, B-PRI sub-pump, B-ACC sub-pump. Among them, the A-PRI sub-pump is the main pump of the A pump unit, the A-ACC sub-pump is the auxiliary pump of the A pump unit, the B-PRI sub-pump is the main pump of the B pump unit, and the B-ACC sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com