A detachable expansion bolt casing

A technology of expansion bolts and sleeves, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of increased production processes and increased production costs, and achieve the effects of increasing manufacturing costs, improving reliability, and improving installation quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 2 to 6 To further illustrate the specific implementation of a detachable expansion bolt sleeve of the present invention. The detachable expansion bolt sleeve of the present invention is not limited to the description of the following embodiments.

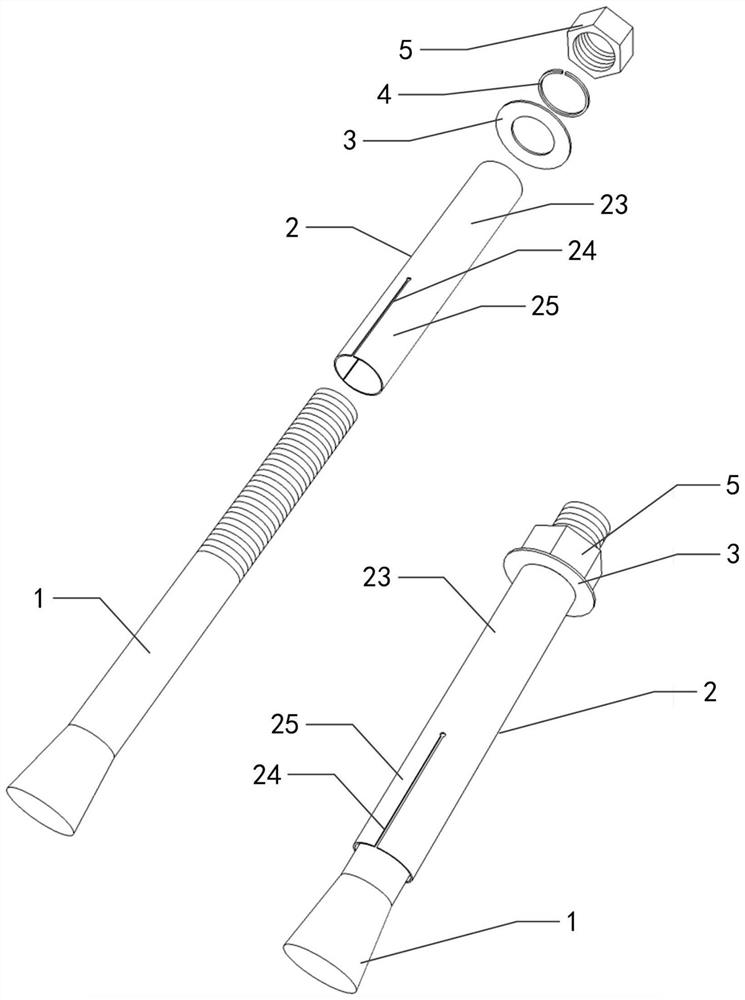

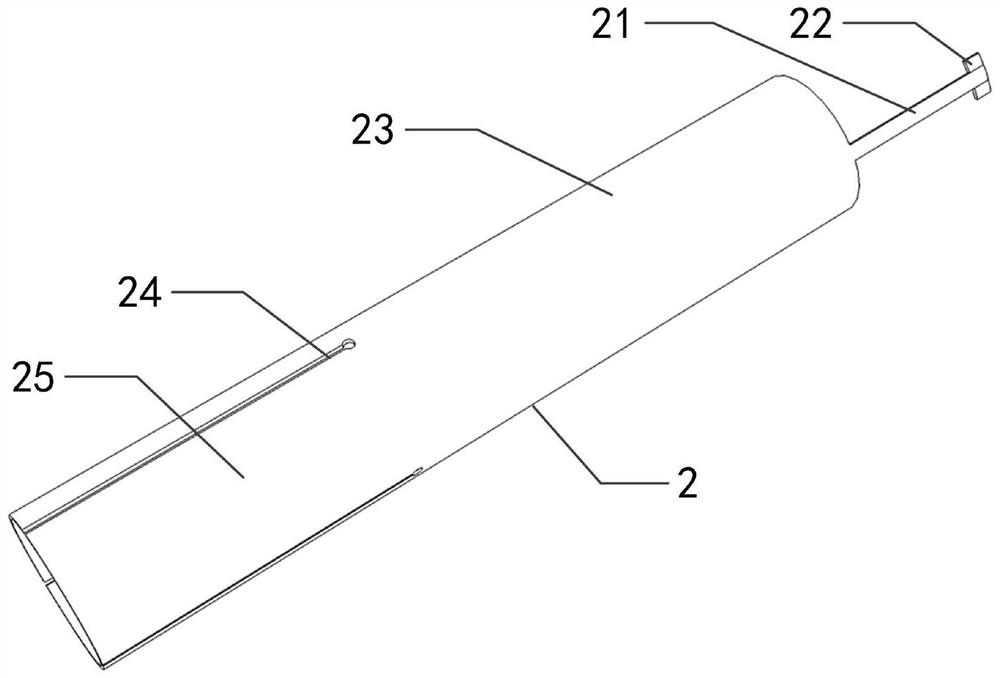

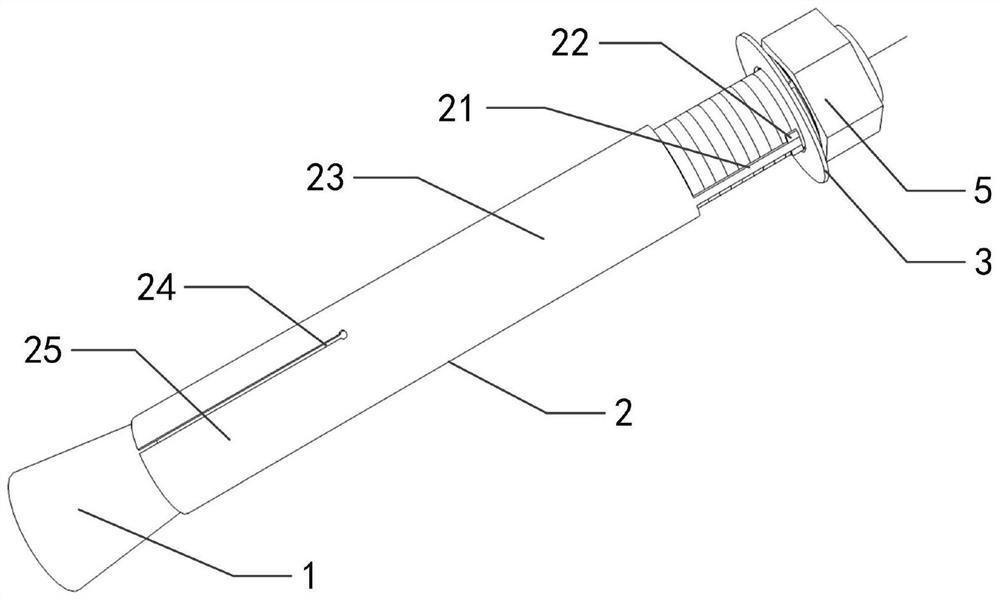

[0032] Such as figure 2 As shown, a detachable expansion bolt sleeve includes a sleeve section 23 and an expansion section 25. The outer end of the sleeve 2 is provided with an extension section 21 extending outward along the direction of the busbar of the sleeve 2, and the end of the extension section 21 extending outward is provided with a clamping point 22. The clamping point 22 and the extension section 21, the sleeve section 23 and the expansion section 25 of the sleeve 2 are integrally stamped and formed, or integrally cut and formed. Such as image 3 As shown, it is a schematic diagram of the overall structure of an expansion bolt formed by assembling the sleeve 2 of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com