Vaccine container with failure indicator and failure indication method thereof

A technology of indicators and vaccines, applied in instruments, scientific instruments, thermometers with physical/chemical changes, etc., can solve problems such as no definite and achievable solution, inappropriate temperature control, difficult monitoring, etc., to reduce the loss of vaccines , Reduce vaccination accidents and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

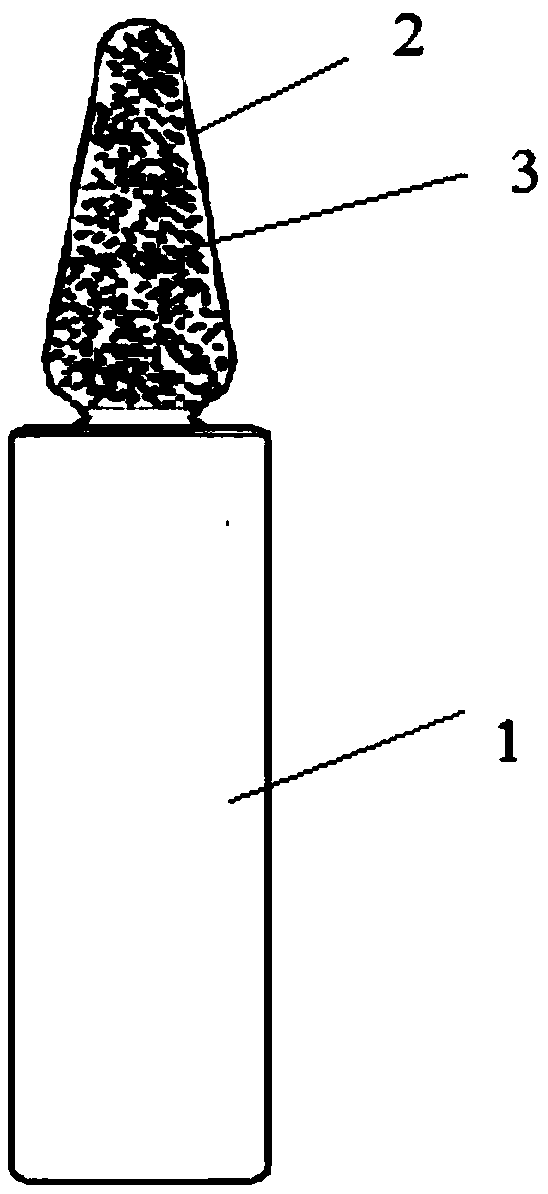

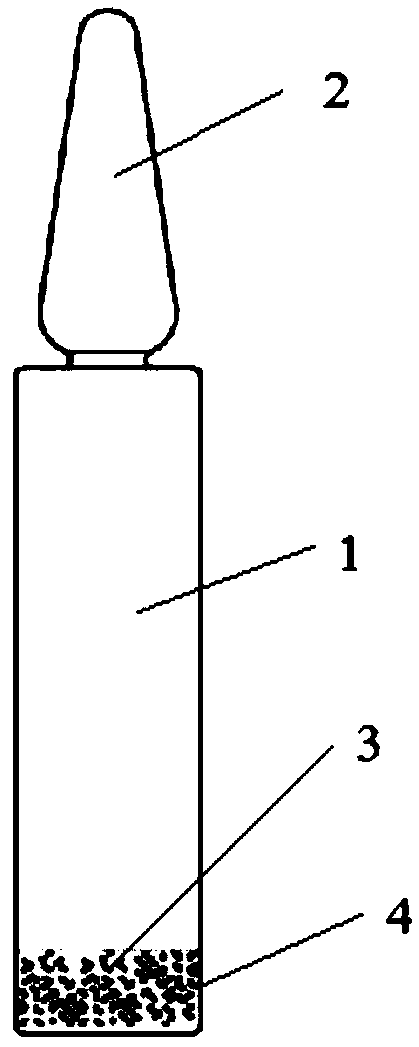

Image

Examples

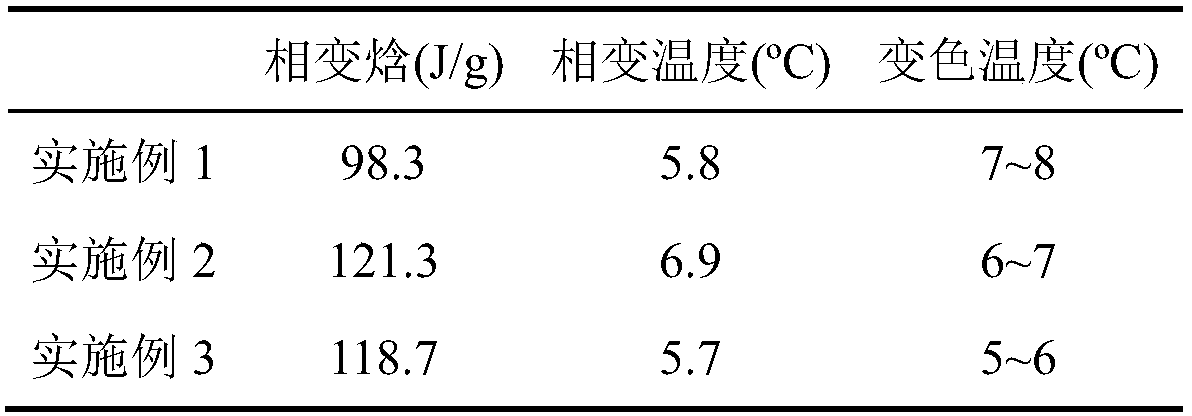

Embodiment 1

[0048] A preparation method of failure indicator, comprising the steps of:

[0049] 1) Preparation of component A: Add 5 g of propylene glycol monostearate into 75 g of n-tetradecane at a temperature of 25° C., and mix evenly with a magnetic stirrer. While stirring, 5 g of sodium carbonate solution with a mass fraction of 5% was added dropwise, and the stirring was continued for 30 min. After the mixture was placed in a -5°C environment for 2 hours, it was pulverized with a pulverizer to obtain component A.

[0050] 2) Preparation of component B: Add 1 g of sorbitan sesquioleate into 80 g of n-tetradecane at a temperature of 25° C., and mix evenly with a magnetic stirrer. Add 1 g of phenolphthalein indicator (mass ratio: phenolphthalein: ethanol: water = 1:94:5) dropwise while stirring, and continue stirring for 40 min. After the mixture was placed at -3°C for 3 h, it was pulverized with a pulverizer to obtain component B.

[0051] 3) In the -5°C environment, mix component ...

Embodiment 2

[0053] A preparation method for failure indicator, comprising the steps of:

[0054] 1) Preparation of component A: Add 2g of diethylene glycol monooleate into 90g of n-decyl alcohol at a temperature of 25°C, and mix evenly with a magnetic stirrer. While stirring, 10 g of 1% sodium hydroxide solution was added dropwise, and the stirring was continued for 60 min. After the mixture was placed in an environment at 3° C. for 5 h, it was pulverized with a pulverizer to obtain component A.

[0055] 2) Preparation of component B: at a temperature of 25°C, 7g of glyceryl monostearate was added to 95g of n-decyl alcohol, and mixed uniformly with a magnetic stirrer. While stirring, 5 g of phenolphthalein indicator (mass ratio: phenolphthalein: ethanol: water = 2:90:8) was added dropwise and continued to stir for 60 min. After the mixture was placed in an environment of 0° C. for 4 h, it was pulverized with a pulverizer to obtain component B.

[0056] 3) In an environment of 0°C, mix ...

Embodiment 3

[0058] A preparation method of failure indicator, comprising the steps of:

[0059] 1) Preparation of component A: Add 6 g of sorbitan fatty acid ester to 80 g of methyl tridecanoate at a temperature of 25° C., and mix evenly with a magnetic stirrer. While stirring, 20 g of 3% sodium bicarbonate solution was added dropwise, and the stirring was continued for 45 min. After the mixture was placed at -1°C for 2 hours, it was pulverized with a pulverizer to obtain component A.

[0060] 2) Preparation of component B: Add 0.5 g of sorbitan sesquioleate into 90 g of methyl tridecanoate at a temperature of 25° C., and mix evenly with a magnetic stirrer. Add 2.5 g of phenolphthalein indicator dropwise while stirring (mass ratio: phenolphthalein: ethanol: water = 2:93:5) and continue stirring for 30 min. After the mixture was placed at -2°C for 5 hours, it was pulverized with a pulverizer to obtain component B.

[0061] 3) In an environment of -2°C, mix component A and component B un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap