Grinding tableting machine

A tablet press and tablet press technology, applied in the direction of sampling, measuring devices, instruments, etc., can solve problems such as the difficulty of grinding solid samples, achieve the effects of reducing the influence of uncertain factors, improving the accuracy of experiments, and making tablets efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

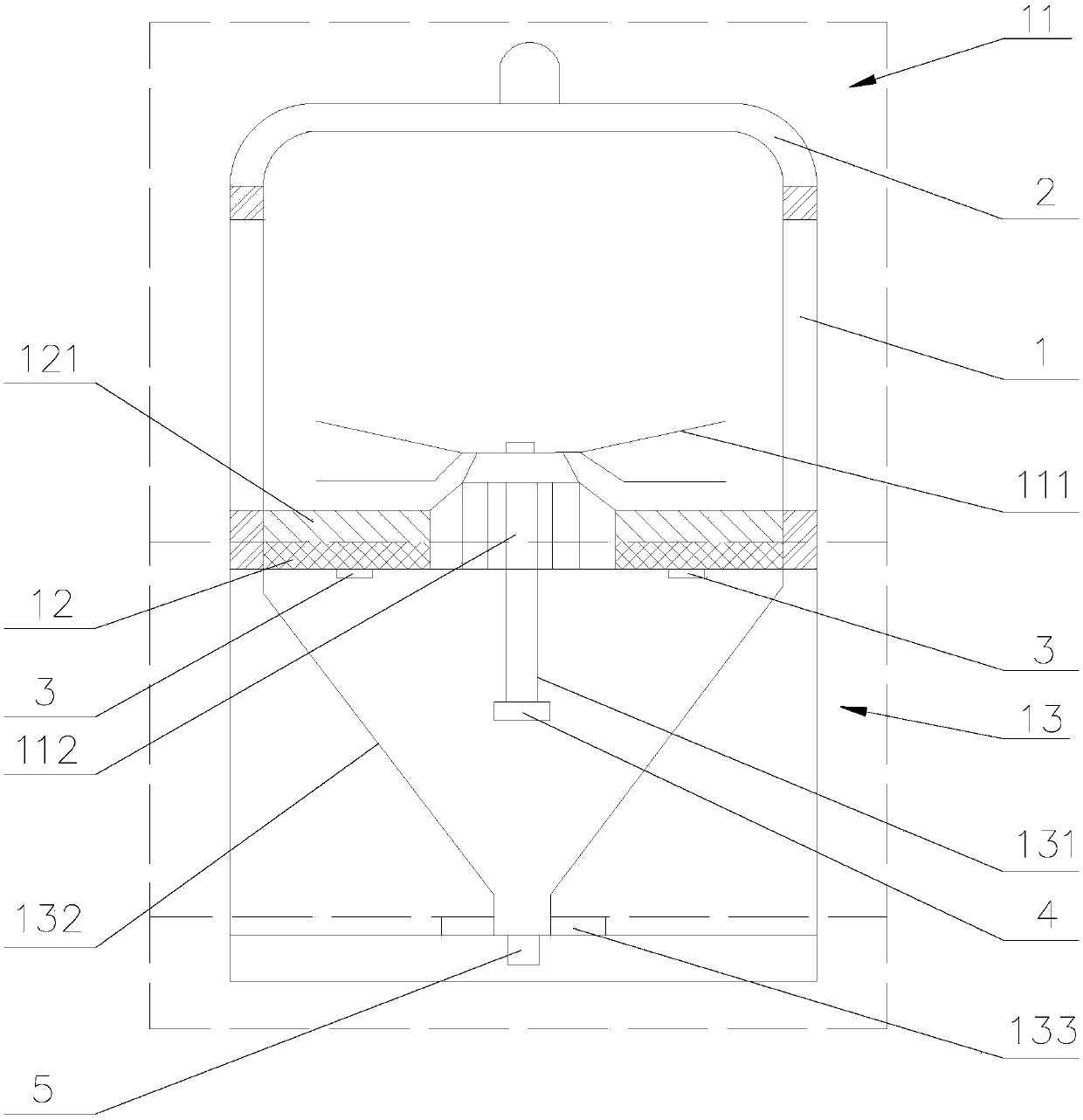

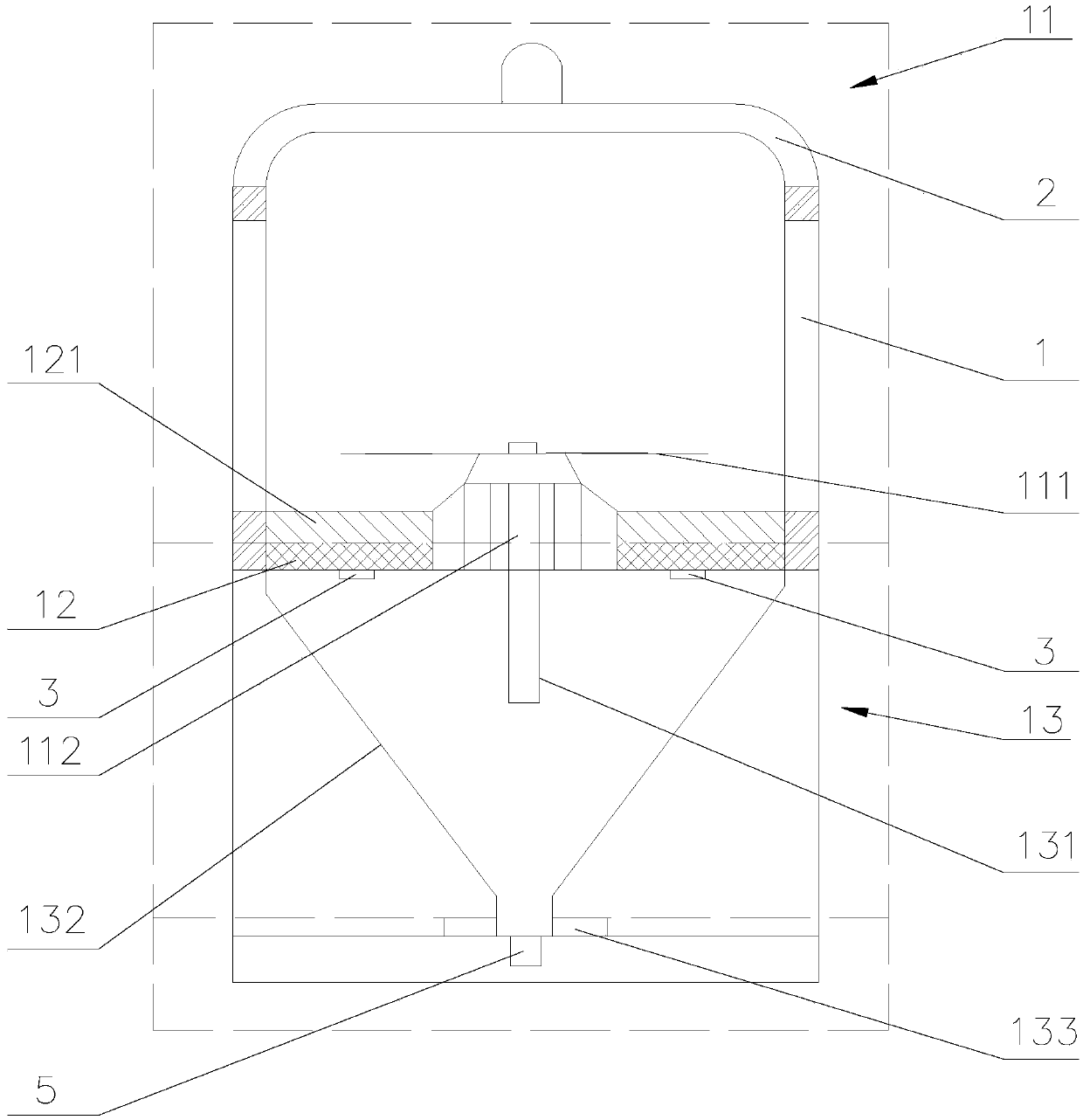

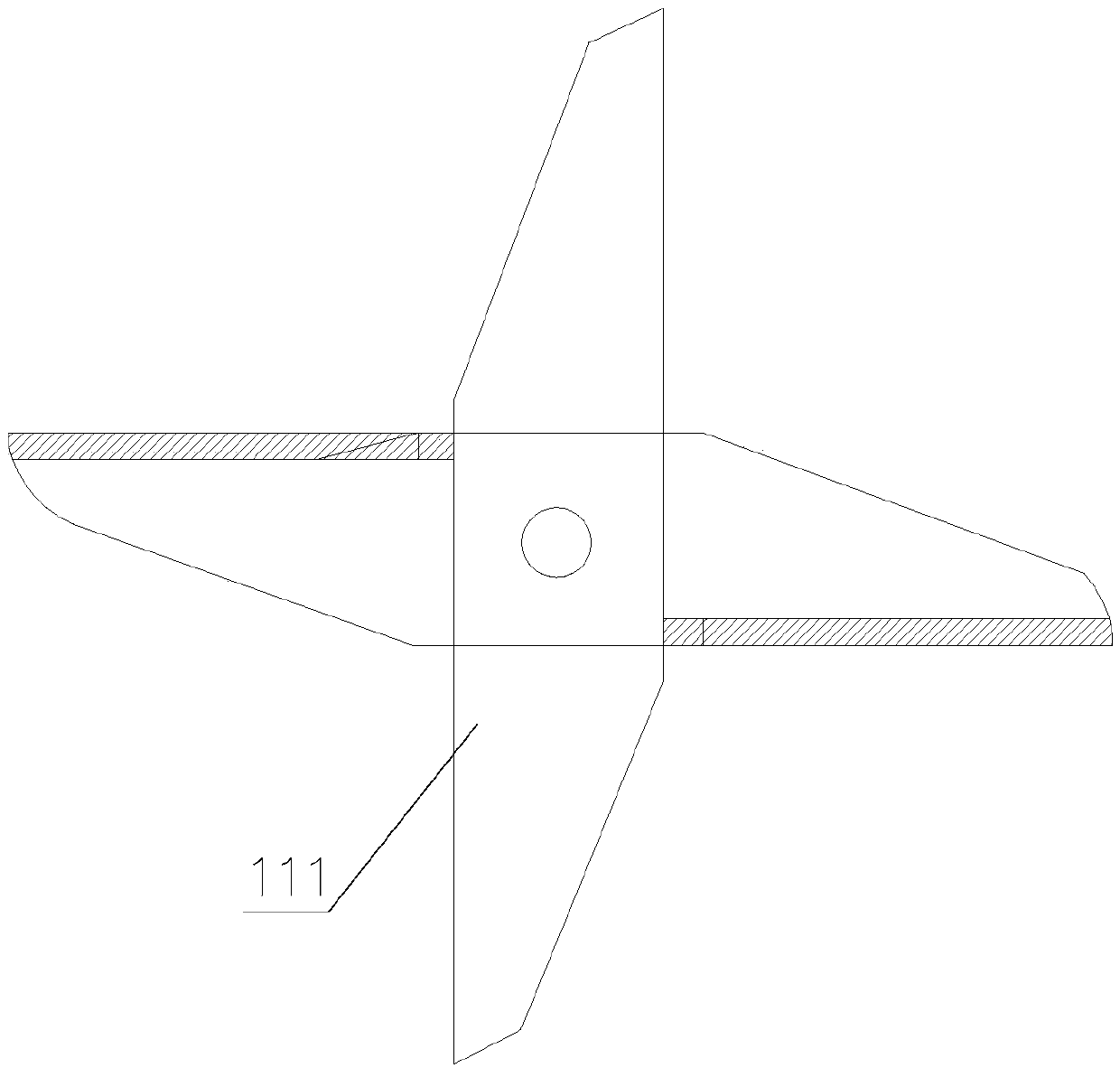

[0036] see Figure 1 to Figure 4 , the present invention provides a grinding tablet press, comprising a shell 1 with an upper opening, an upper cover 2, and a crushing chamber 11, a screening part, and a tablet pressing chamber 13 arranged in the shell, and the upper cover is set on the shell At the opening of the tablet press, the working chamber of the grinding tablet press is formed between the upper cover and the housing, and the upper cover is screwed or buckled to the upper opening of the housing. The crushing chamber is used to crush the solid samples. The screening part is set between the crushing chamber and the tablet pressing chamber. Above the part, the solid samples with particle size meeting the requirements pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com