An avionics case with internal module stack structure form connection

An avionics, stack structure technology, applied in the direction of electrical digital data processing, digital processing power distribution, digital data processing components, etc., can solve the problem of occupying functional modules, effectively arranging device area waste, and the area is difficult to meet the function and performance. requirements, etc., to achieve the effect of high heat dissipation efficiency and minimized chassis size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

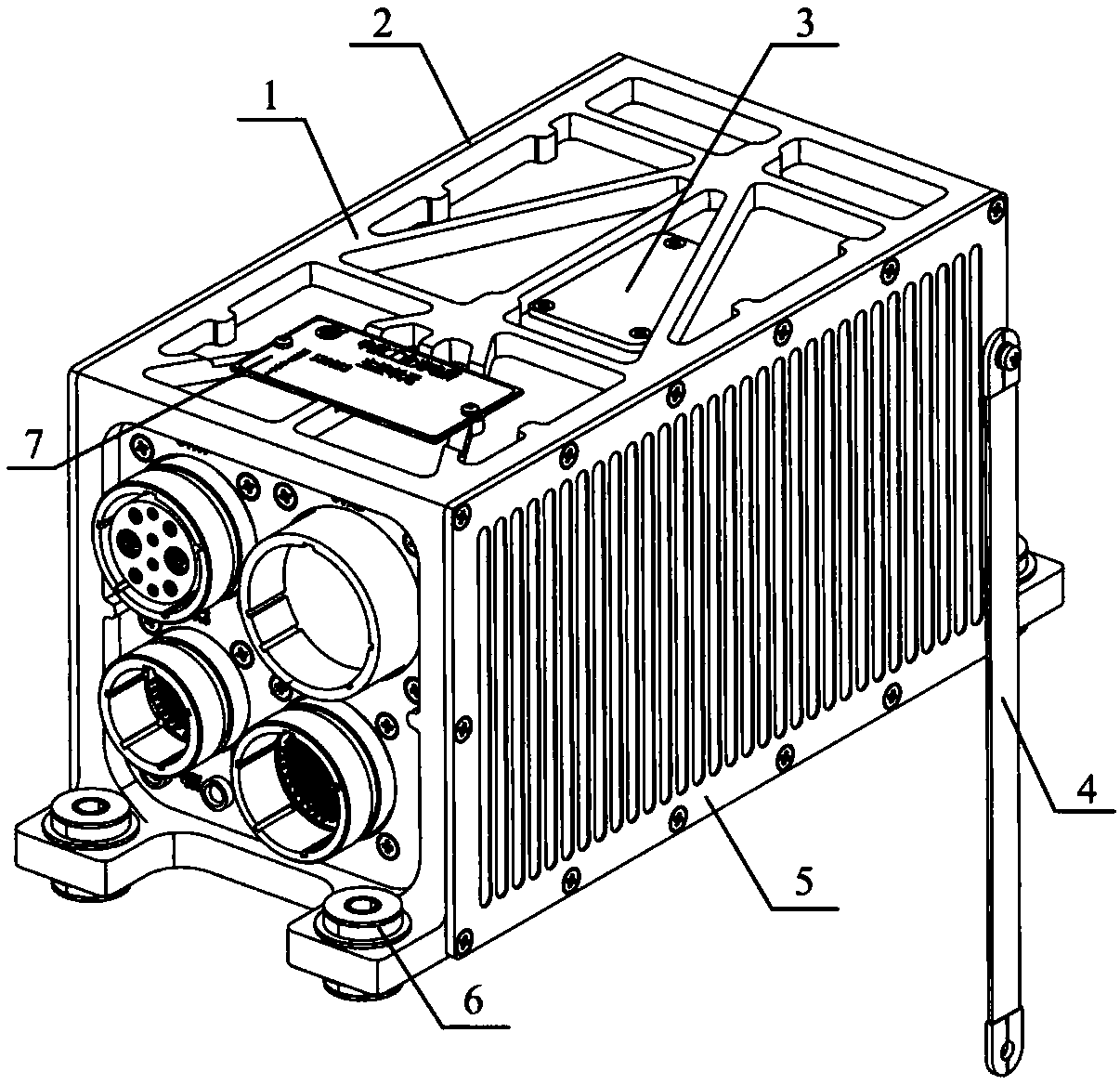

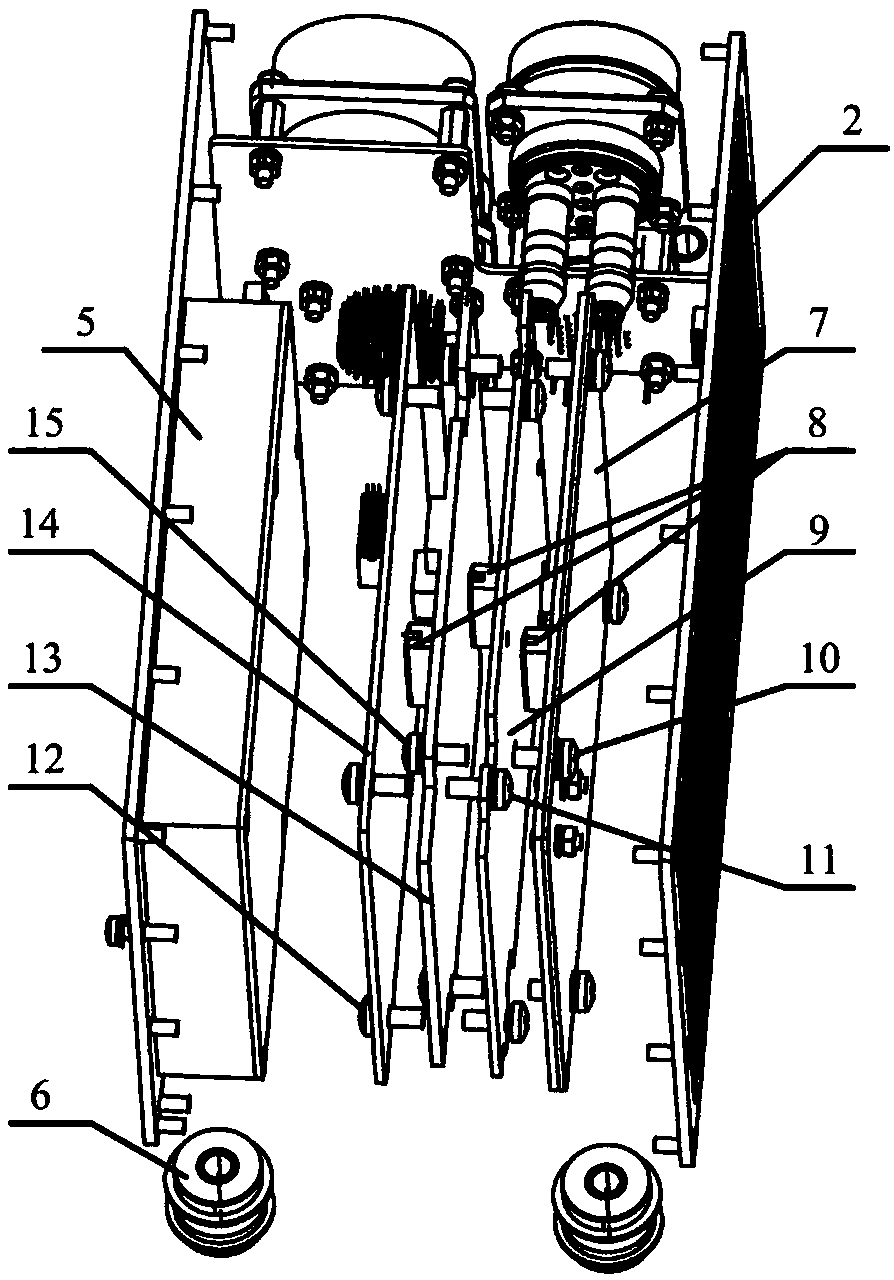

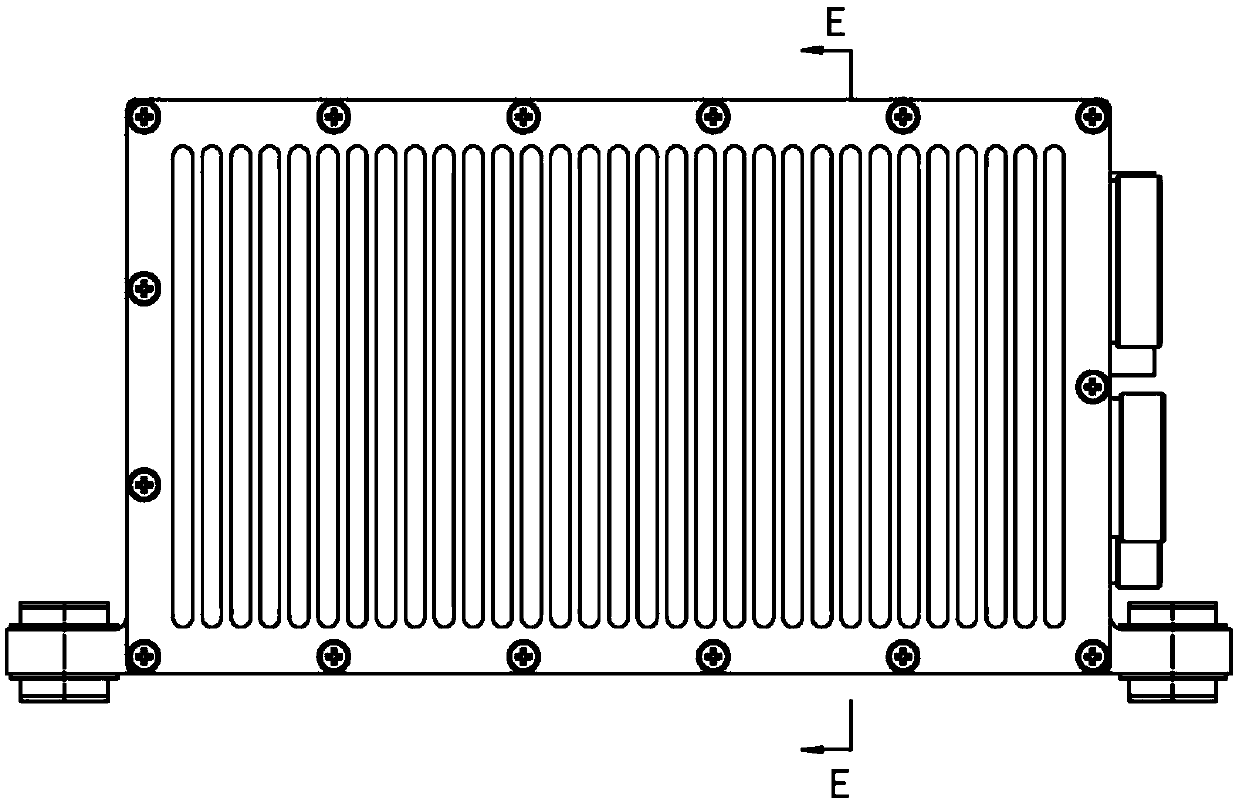

[0029] see Figure 1 to Figure 12 , the avionics case of the present invention is installed in the hanger made of square tube profiles of the aircraft. In view of the small size of the installation space, large vibration level, and many functions required by users, if the traditional screw splicing / vacuum brazing splicing of the case is used The body, the fixing of the printed board slider locker, and the communication structure of the motherboard cannot meet the requirements of use.

[0030] The present invention proposes an avionics case connected in a stacked structure of internal modules to maximize the area of the effective arrangement of devices on the printed board of the modules in the case, thereby minimizing the overall size of the case, and the integrated forming of the case body to meet the requirements of high strength. Vibration require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com