Rotary peanut shelling device for seeds

A technology for peanuts and sets, which is applied in the fields of application, threshing equipment, agricultural machinery and tools, etc., can solve the problems of peanut broken and high damage rate, low shelling quality, harsh production environment, etc., to achieve planting and yield increase, threshing The quality of the shell is good and the effect of ensuring the germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

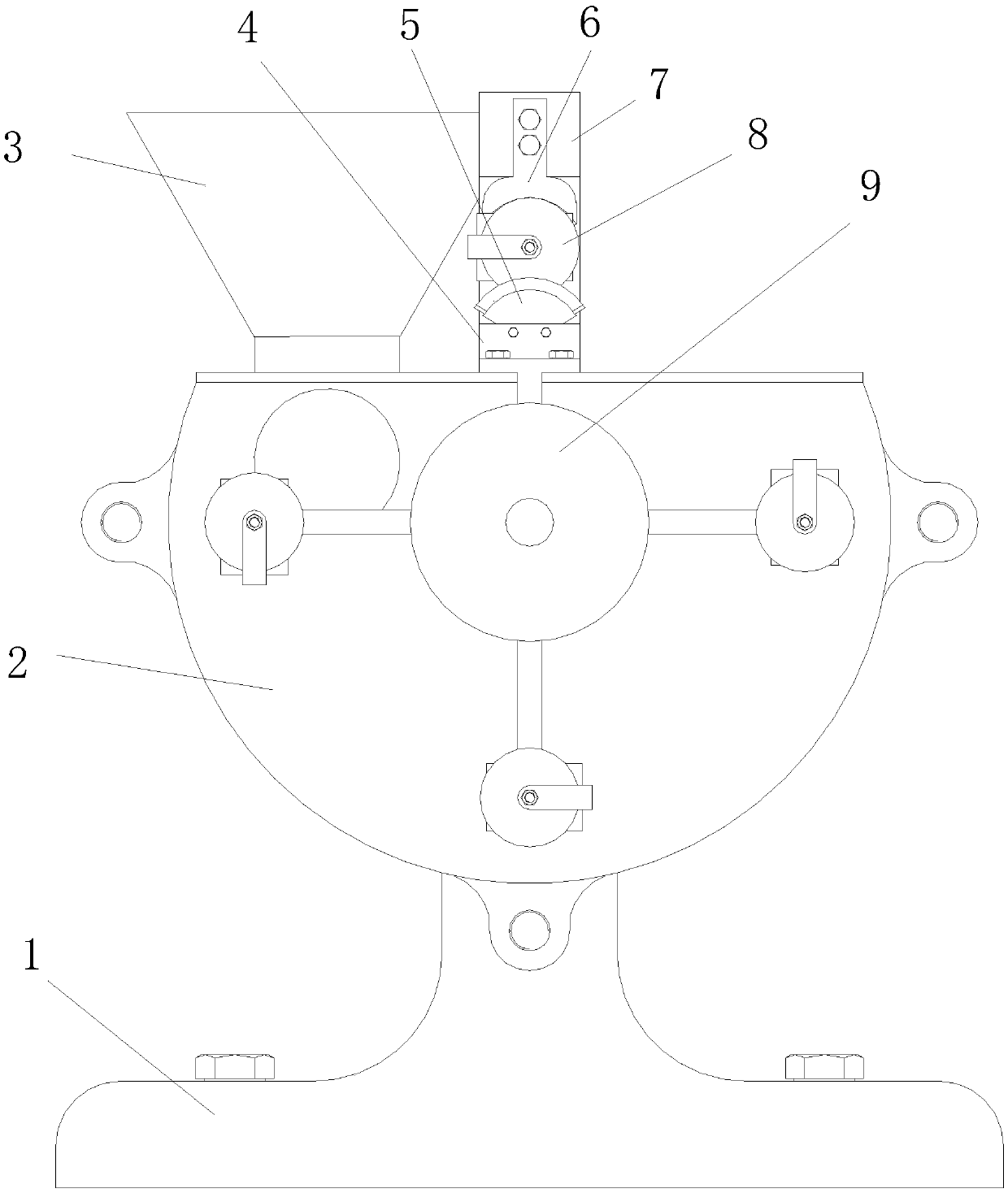

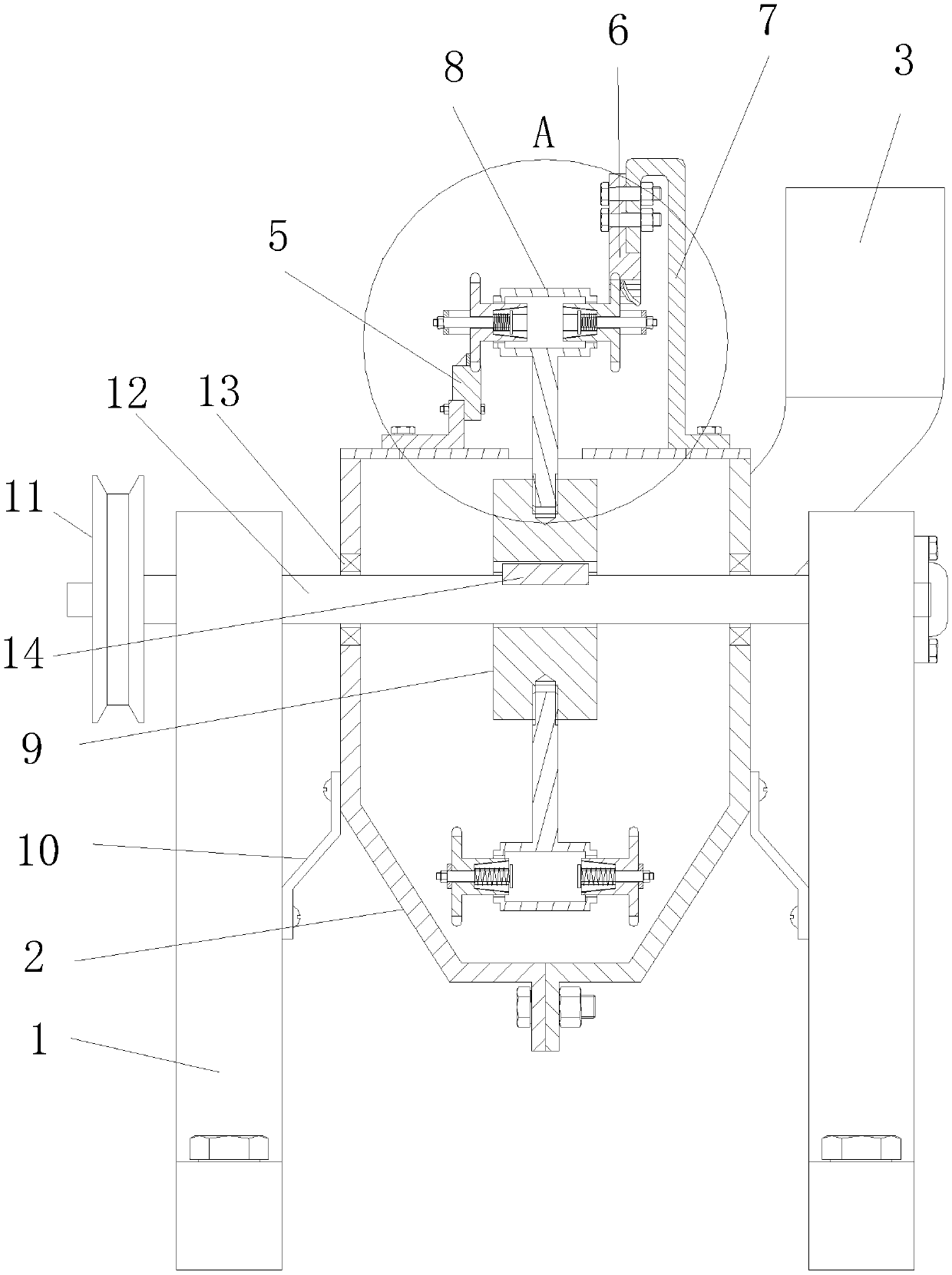

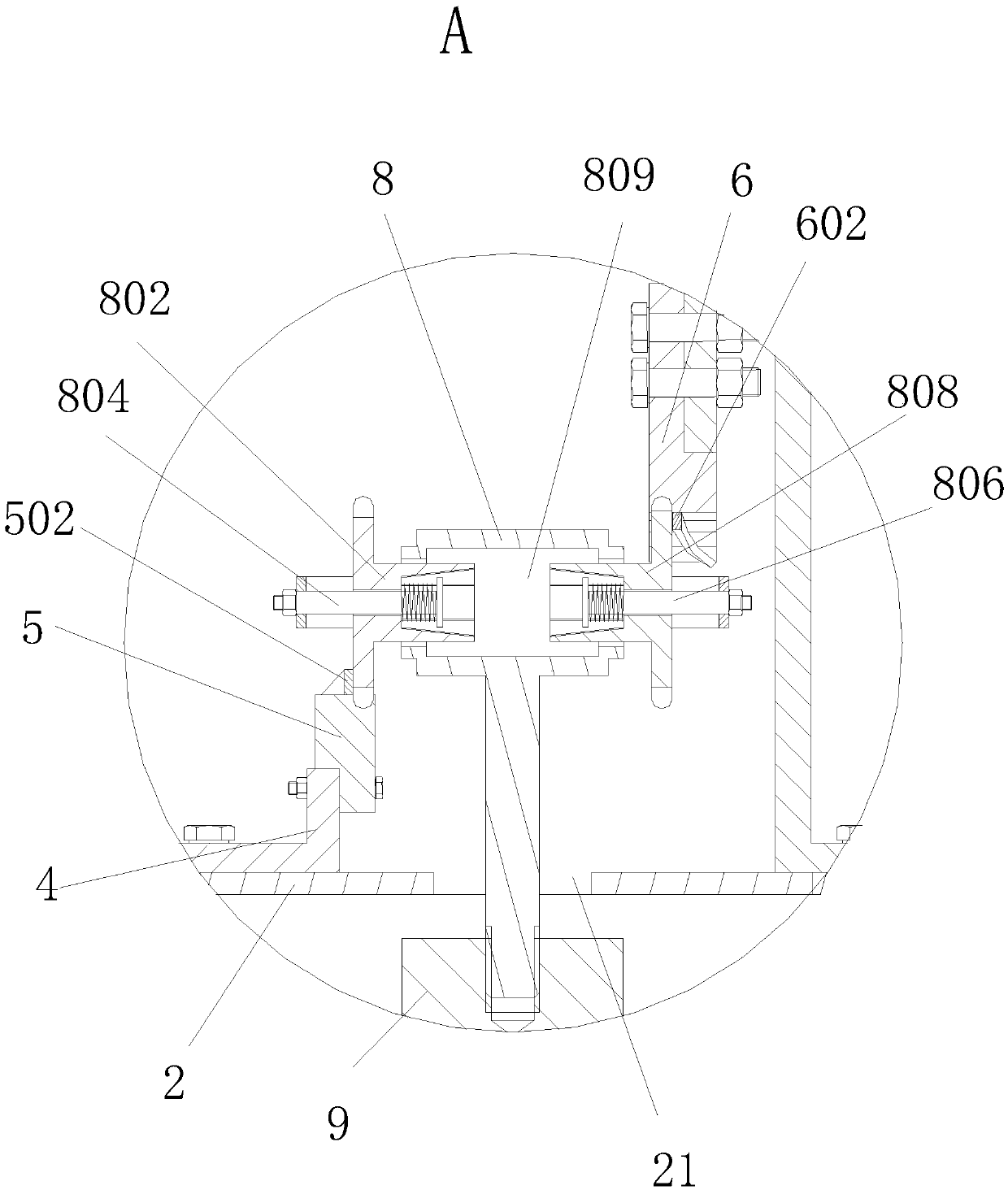

[0033] See Figure 1 to Figure 13 This embodiment discloses a twisted seed peanut shelling device, which includes a support 1 on which a seed chamber 2 is fixedly arranged, and the seed chamber 2 is fixedly connected to the support 1 through a connecting plate 10. The top of one side of the seed chamber 2 is provided with a hopper 3, the shape of the seed chamber 2 is a disk-shaped structure, and the bottom of the seed chamber 2 is inverted cone shape laterally, so that the sheller 8 can take seeds. The two ends of the transmission shaft 12 are rotatably connected with the support 1 after passing through the seed chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com