A field paving machine

A technology for laying trays and fields, applied in the field of field tray laying machines, can solve the problems of manual work, inability to complete the work of raising seedling trays, and achieve the effects of flexible movement, rich tray laying paths, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

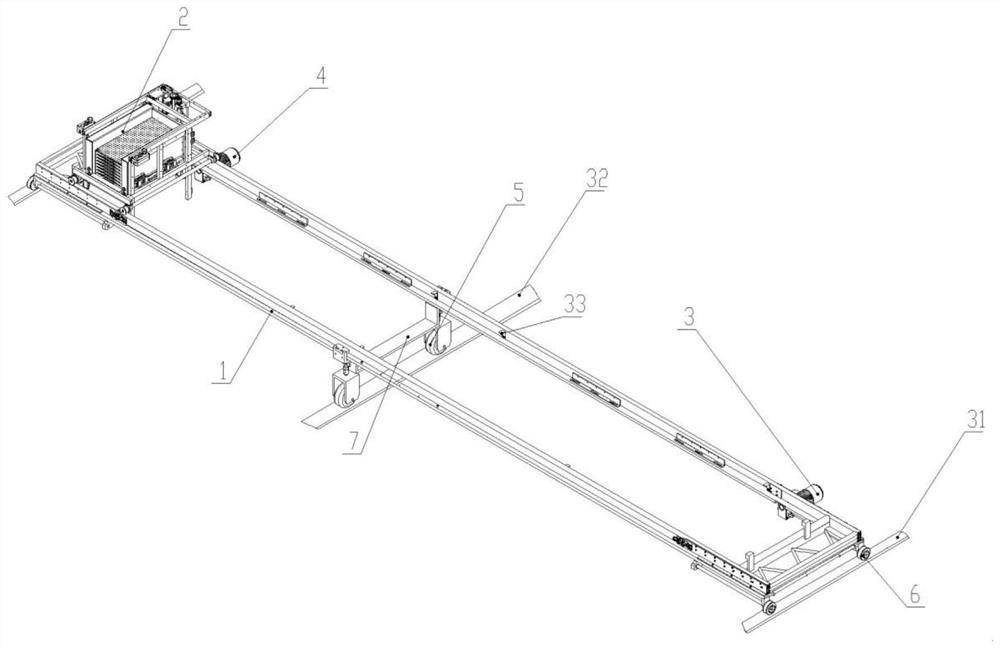

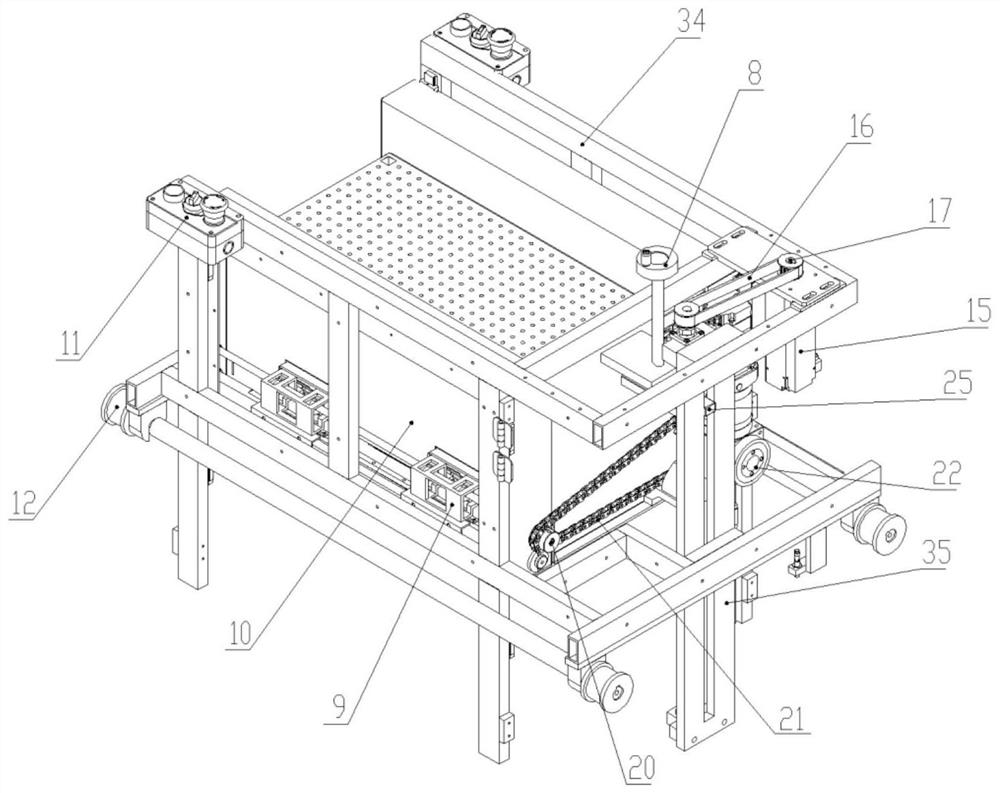

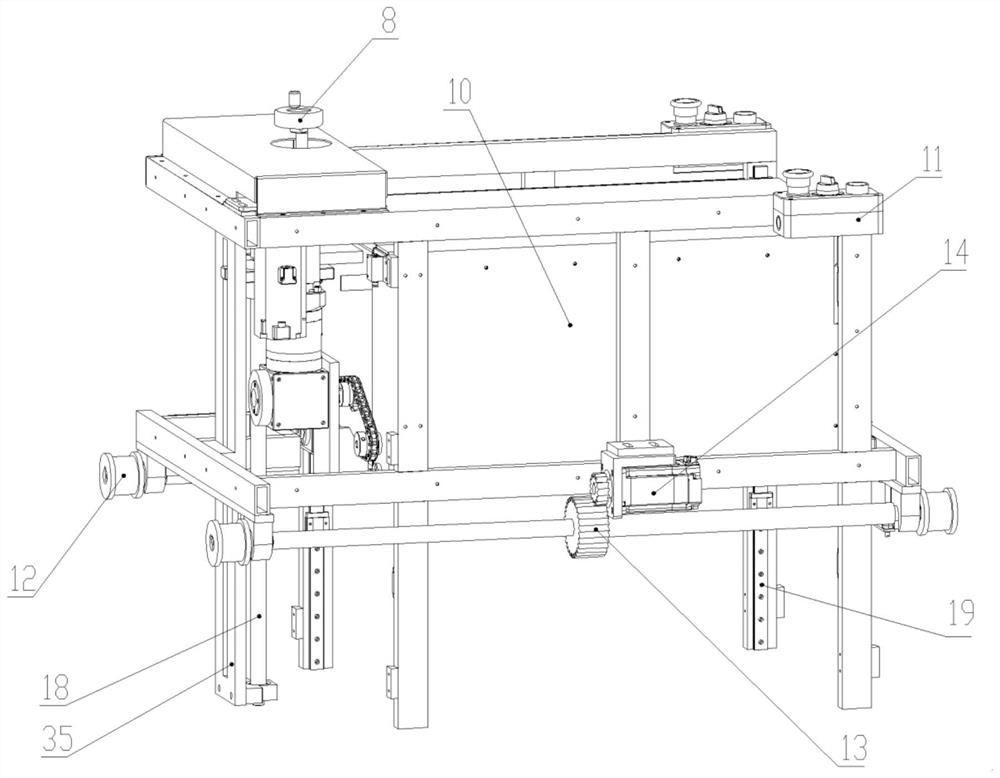

[0033] Such as figure 1 As shown, the field paving machine includes a ridge-direction power guide rail 31, a ridge-direction auxiliary guide rail 32, a longitudinal moving device and a pavement trolley 2. The ridge direction auxiliary guide rail 32 and the two ridge direction power guide rails 31 are all arranged along the ridge direction of the field. The ridge direction auxiliary guide rail 32 is fixed between two adjacent ridge fields. Two ridge guide rails are respectively fixed on both sides of the two ridge fields (that is, the ridge-direction auxiliary guide rail 32 and the two ridge-direction power guide rails 31 are respectively fixed between three adjacent ridges).

[0034] The longitudinal moving device includes a Hall sensor 33, a moving guide rail 1, a connecting frame, a support frame 7, a first reduction motor 3, a second reduction motor 4, an intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com