Automatic assembling machine for plug of LED lamp

A technology for LED lamps and assembly machines, which is applied to assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing product failure rate, large labor, low efficiency, etc., and achieves convenient operation and installation, simple and effective structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

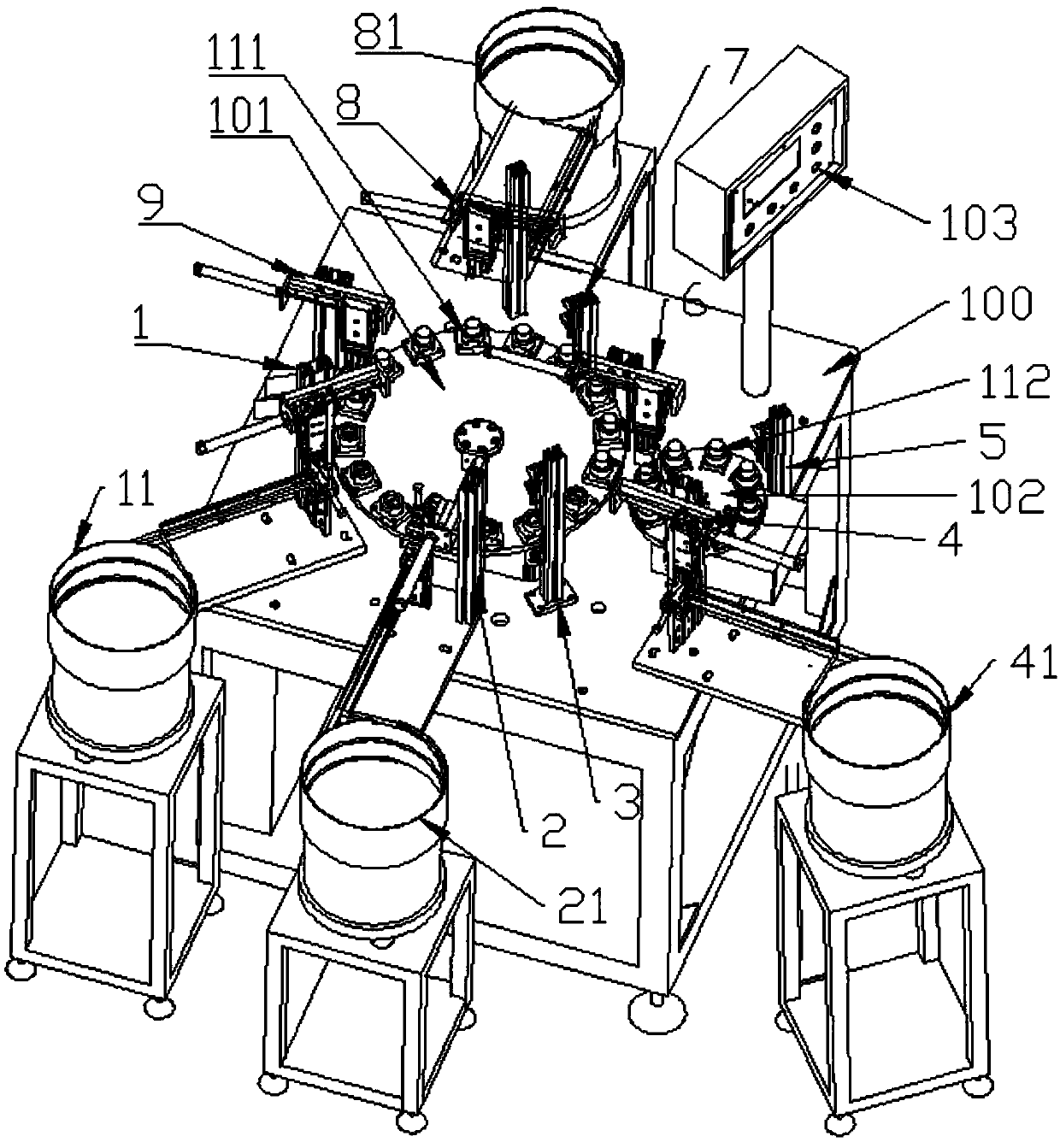

[0051] In order to achieve the purpose of the present invention, a kind of embodiment of the present invention is:

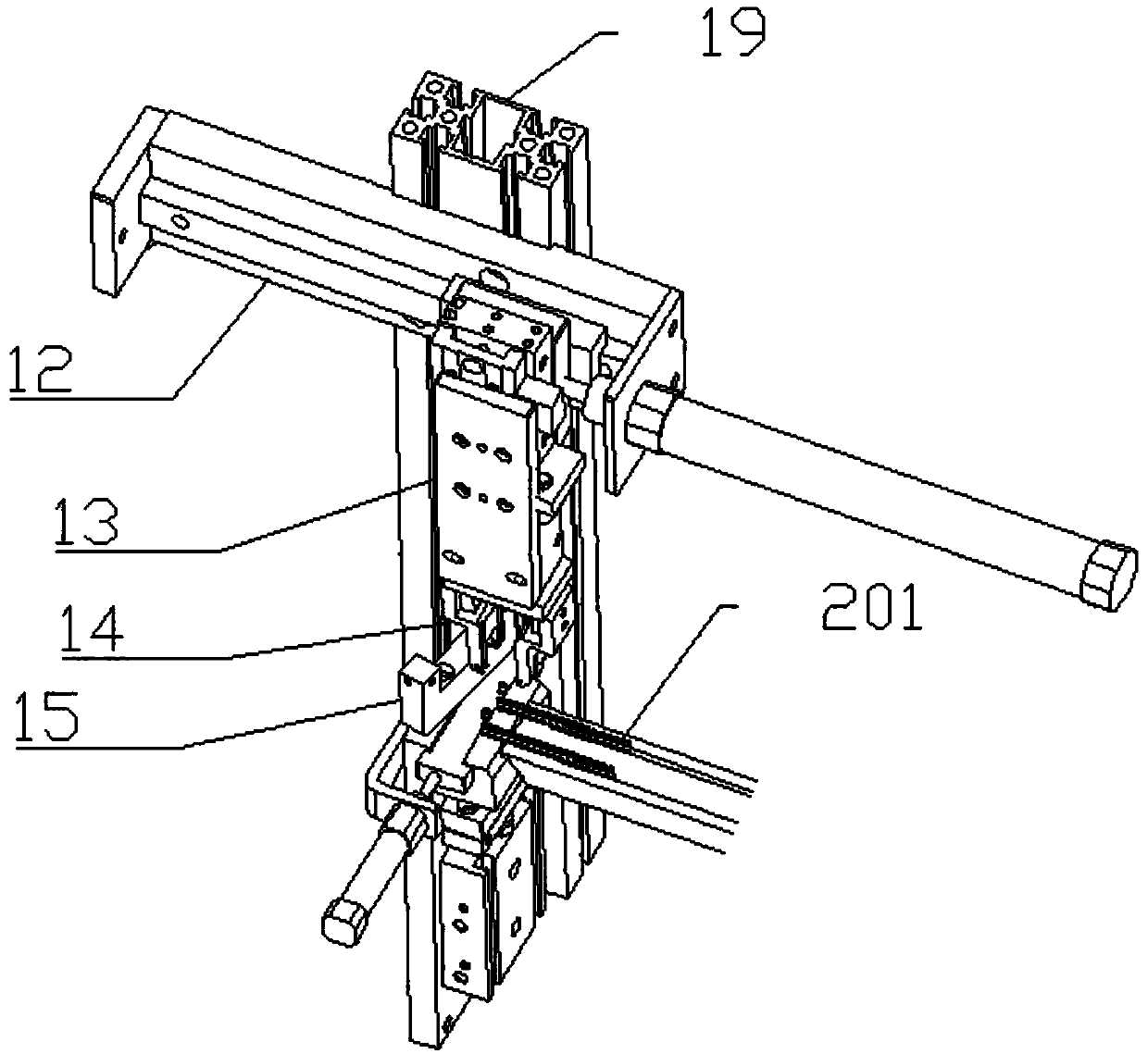

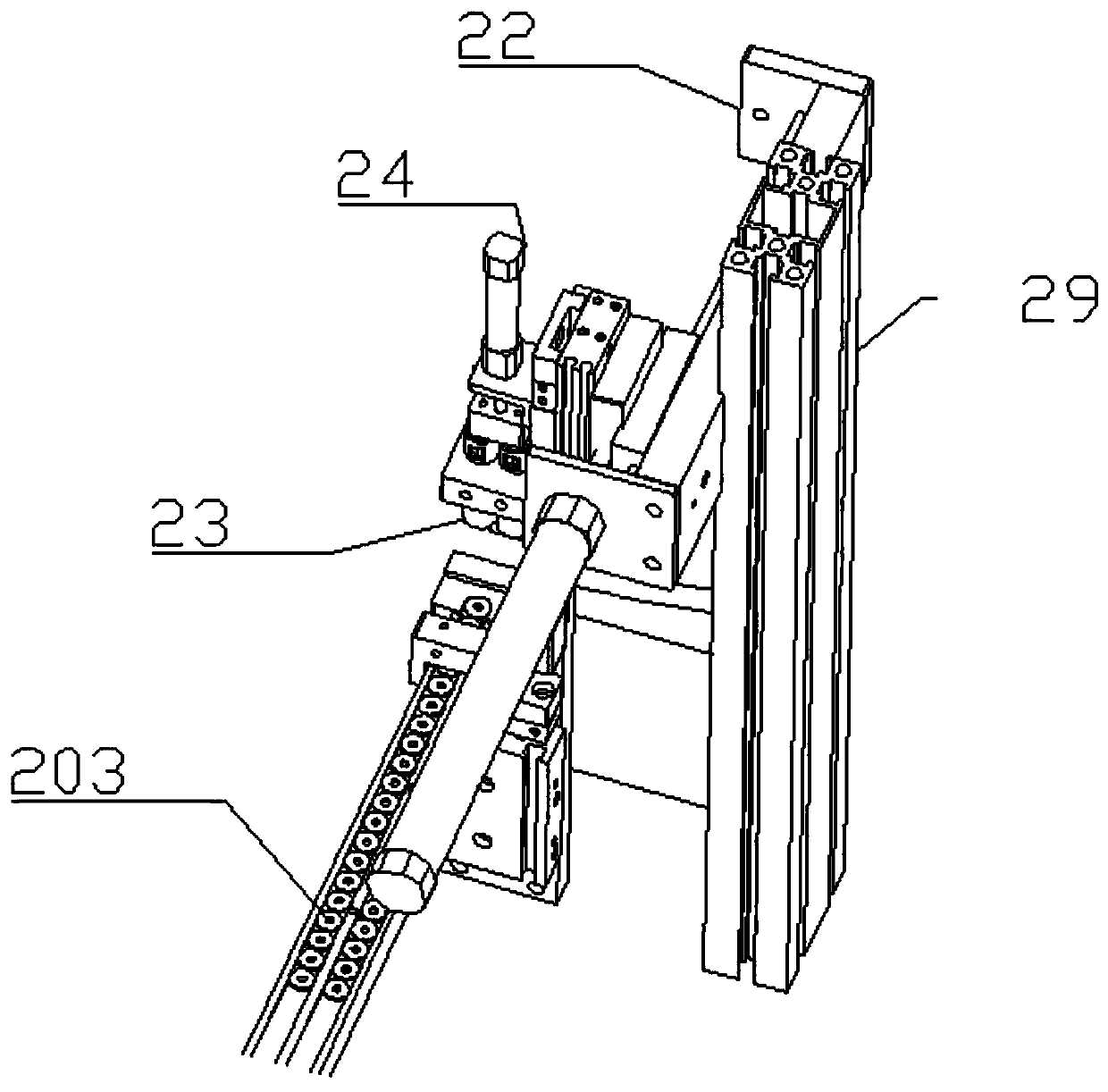

[0052] An automatic plug assembly machine for LED lamps, comprising a machine base 100, a working disc 101, a discharge device 9, a riveting device 7, a copper needle assembly device 11, a black sheet assembly device 22, an inner insulating board assembly device 8 and a control Box 103, the control box 103 is installed on the base 100, the working disc 101 is installed on the base 100 through the base of the disc, the copper needle assembly device 1, the black sheet assembly device 2, The riveting device 7, the inner insulating plate assembly device 8 and the discharge device 9 are rotated and distributed in sequence around the working disc 101, and several plug mounting bases 111 are installed on the working disc 101 at equal intervals and equidistant distances. It includes a small disc 102 for position selection, the small disc 102 for position selection is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com