Mobile phone shell and forming method thereof

A molding method and mobile phone shell technology, applied to the structure of telephones, etc., can solve the problems of easy shedding of the inner fleece layer, short service life of the mobile phone shell, and affecting user experience, so as to improve protection performance, delicate hand feeling, and improve user experience degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

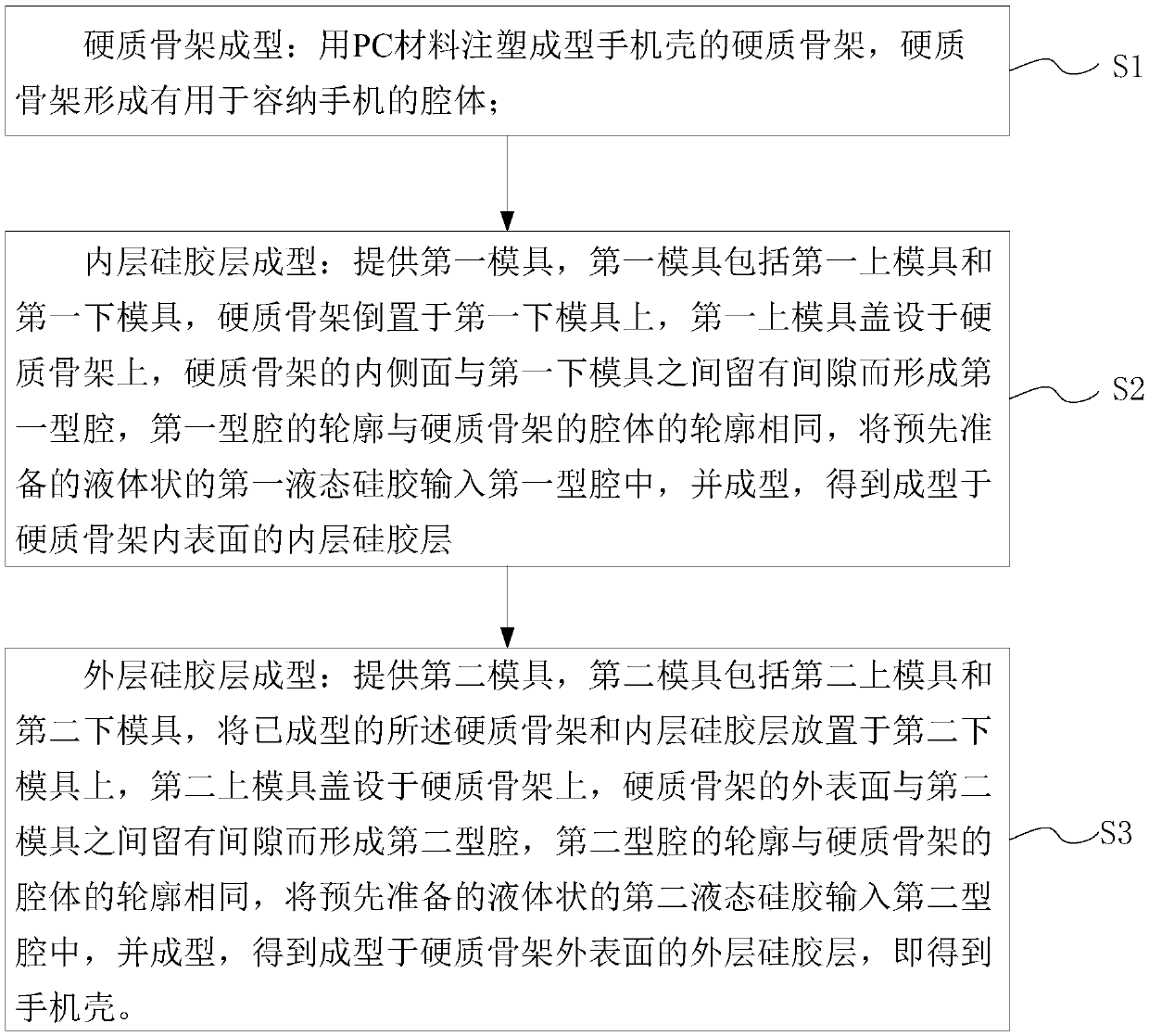

Method used

Image

Examples

Embodiment Construction

[0031] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0032] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

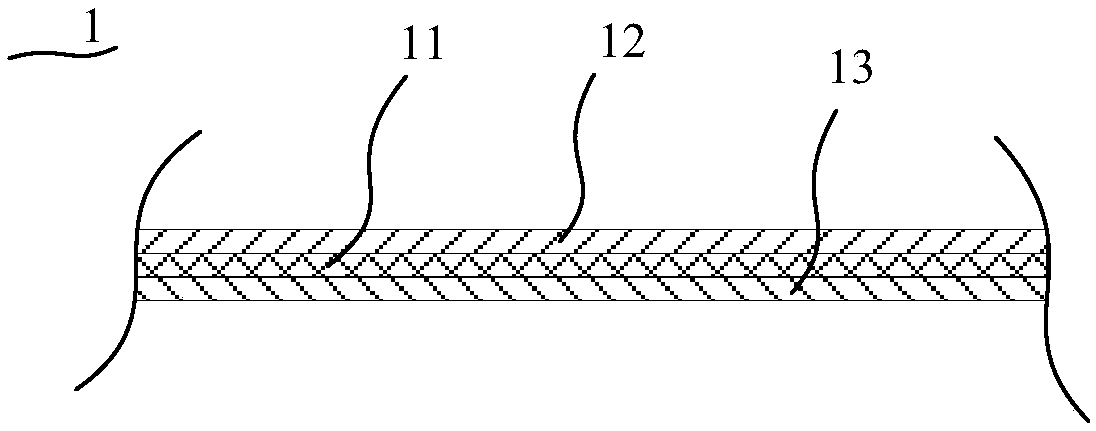

[0033] The present invention provides a mobile phone case 1, the inner and outer surfaces of which are cured by liquid silica gel. Therefore, the mobile phone case is safer, more environmentally friendly and has better performance.

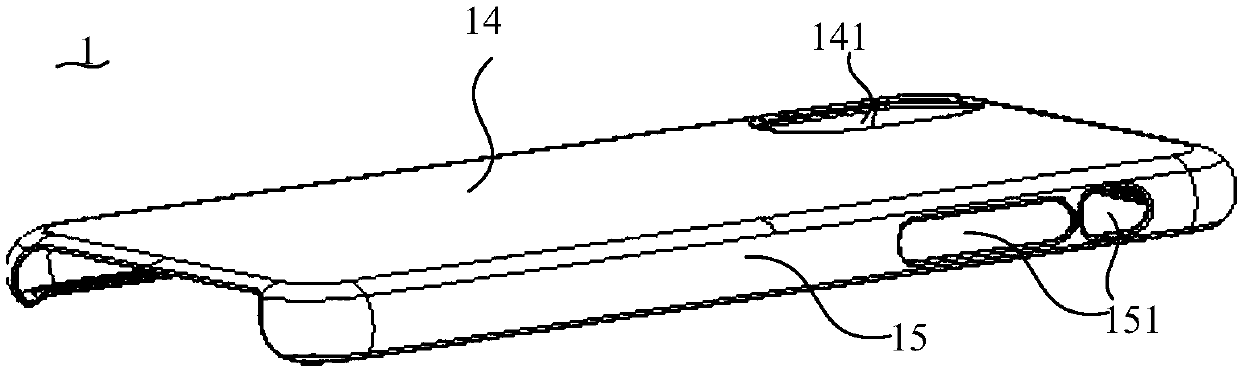

[0034] refer to figure 1 , the mobile phone case 1 includes a case that wraps the back and sides of the mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com