Flocking gloves and production method thereof

A production method and technology of flocking gloves, applied in the field of gloves, can solve problems such as inability to absorb sweat and moisture, discomfort when wearing, wet gloves, etc., and achieve high firmness, easy putting on and taking off, and good foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

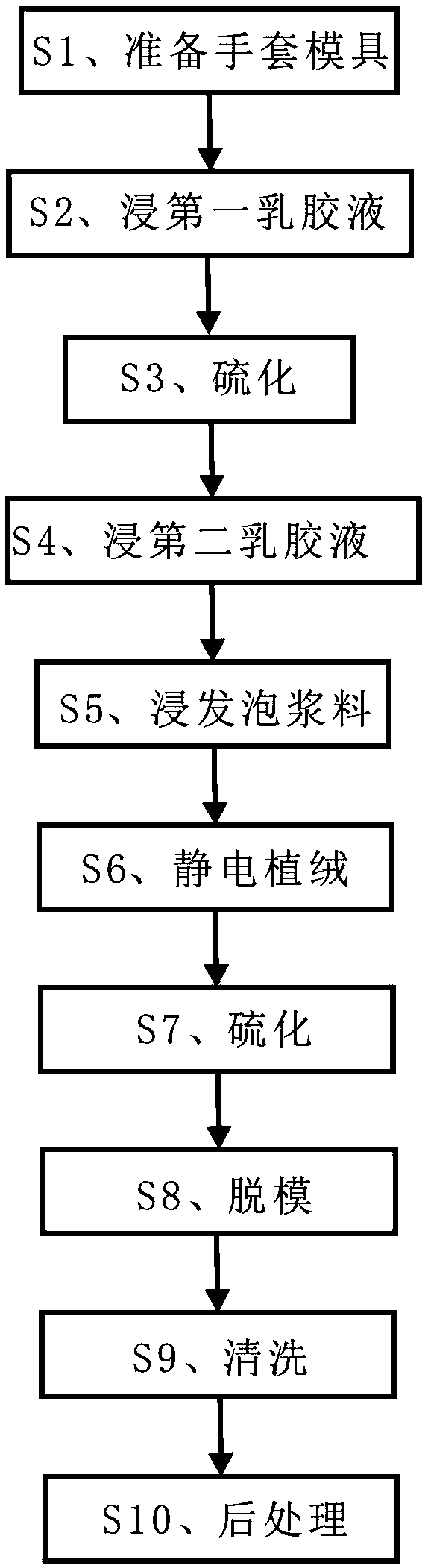

[0040] The embodiment of the present invention discloses a production method of flocked gloves, comprising the following steps:

[0041] S1. Prepare the glove mold: select a suitable glove mold, clean and dry the glove mold, impregnate the glove mold with a coagulant and dry it;

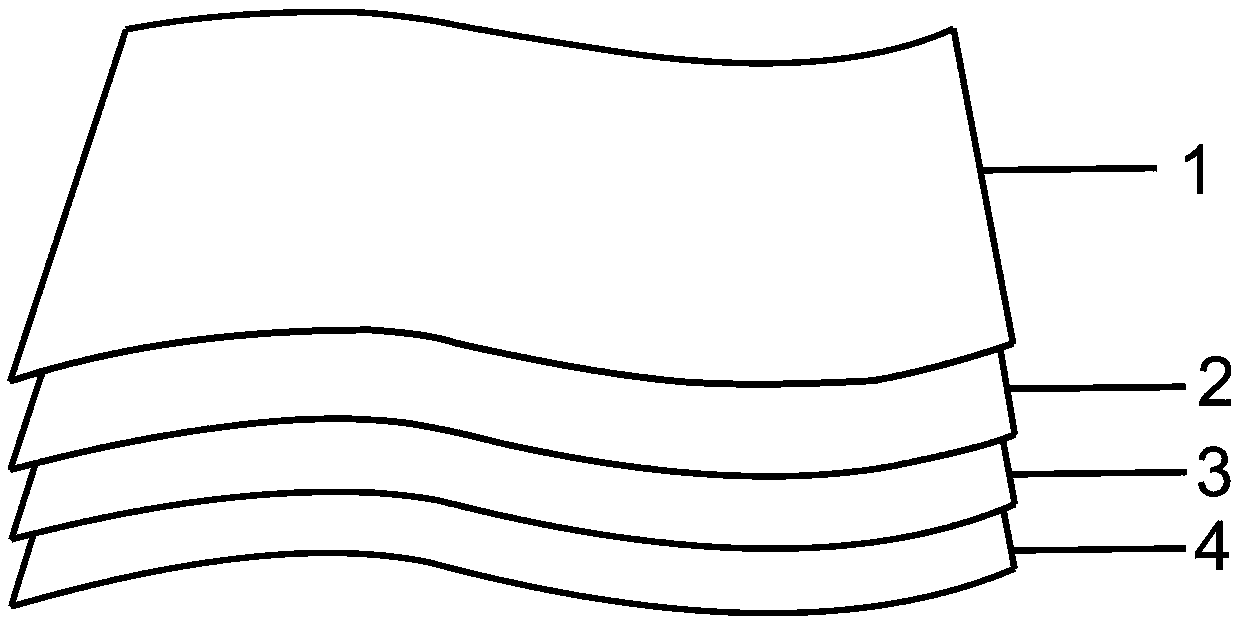

[0042] S2. Soak the first latex solution: prepare the first latex solution, immerse the glove mold prepared in step S1 in the first latex solution for 3 minutes to form the first latex layer; wherein, the first latex layer includes the following parts by weight Components: 80 parts of nitrile latex, 2 parts of lanolin, 15 parts of zinc oxide, 10 parts of titanium dioxide, 20 parts of dispersant;

[0043] S3, vulcanization: vulcanize the glove mold soaked in the first emulsion in step S2;

[0044] S4, soaking in the second latex solution: prepare the second latex solution, immerse the vulcanized glove mold in step S3 in the second latex solution for 3 minutes to form a second latex layer, wherein the...

Embodiment 2

[0057] The embodiment of the present invention discloses a production method of flocked gloves, comprising the following steps:

[0058] S1. Prepare the glove mold: select a suitable glove mold, clean and dry the glove mold, impregnate the glove mold with a coagulant and dry it;

[0059] S2. Soak the first latex solution: prepare the first latex solution, immerse the glove mold prepared in step S1 in the first latex solution for 4 minutes to form the first latex layer; wherein, the first latex layer includes the following parts by weight Components: 72 parts of nitrile latex, 3 parts of lanolin, 10 parts of zinc oxide, 10 parts of titanium dioxide, 5 parts of dispersant;

[0060] S3, vulcanization: vulcanize the glove mold soaked in the first emulsion in step S2;

[0061] S4, soaking in the second latex solution: prepare the second latex solution, immerse the vulcanized glove mold in step S3 in the second latex solution for 3 minutes to form a second latex layer, wherein the ...

Embodiment 3

[0073] The embodiment of the present invention discloses a production method of flocked gloves, comprising the following steps:

[0074] S1. Prepare the glove mold: select a suitable glove mold, clean and dry the glove mold, impregnate the glove mold with a coagulant and dry it;

[0075] S2. Soak the first latex solution: prepare the first latex solution, immerse the glove mold prepared in step S1 in the first latex solution for 3 minutes to form the first latex layer; wherein, the first latex layer includes the following parts by weight Components: 80 parts of nitrile latex, 2 parts of lanolin, 15 parts of zinc oxide, 10 parts of titanium dioxide, 20 parts of dispersant;

[0076] S3, vulcanization: vulcanize the glove mold soaked in the first emulsion in step S2;

[0077] S4, soaking in the second latex solution: prepare the second latex solution, immerse the vulcanized glove mold in step S3 in the second latex solution for 3 minutes to form a second latex layer, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com