Protection system for anti/de-icing experiment of refrigeration tunnel

A protection system and prevention technology, applied in the field of protection systems, can solve the problems of affecting the air duct flow field, reducing the accuracy of the experiment, and the large size of the protective cover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

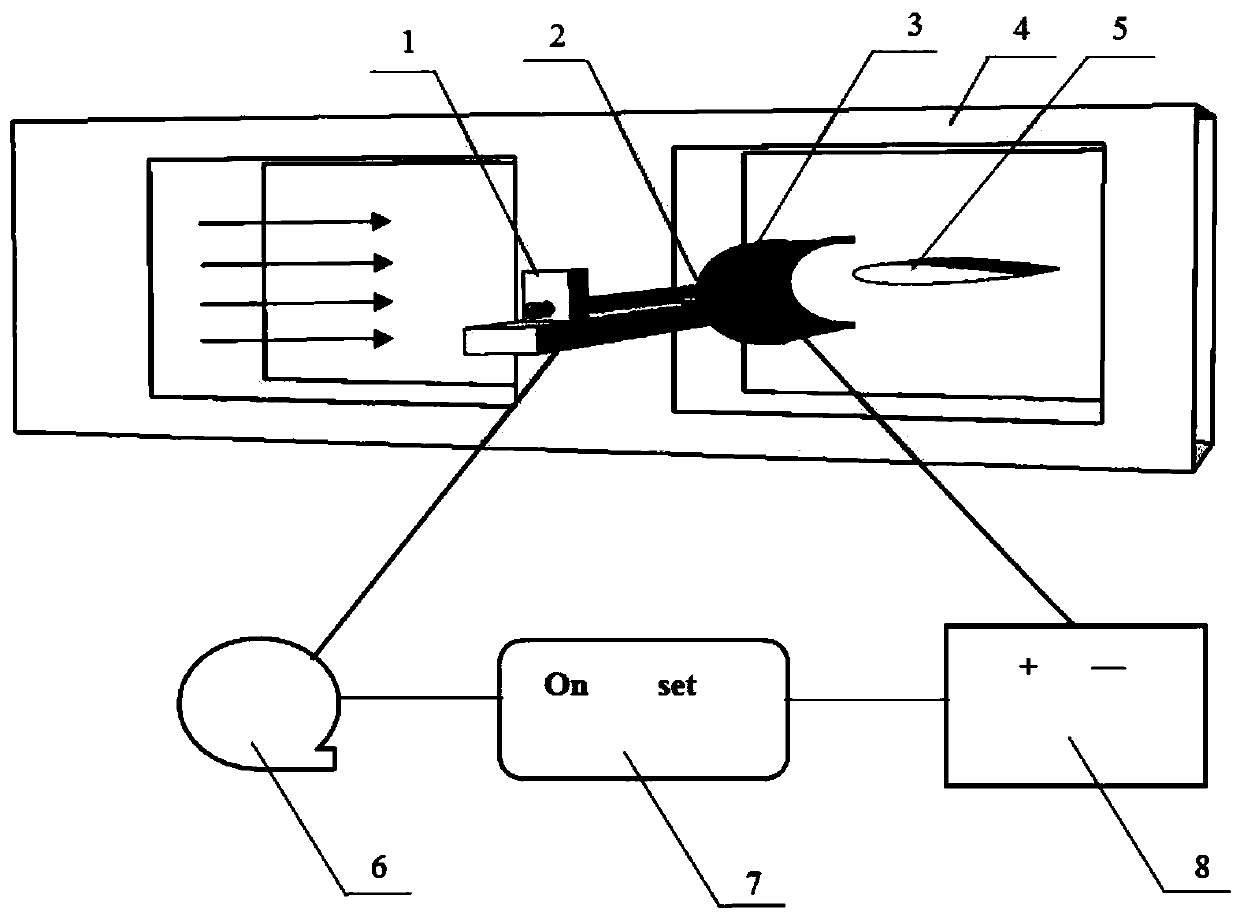

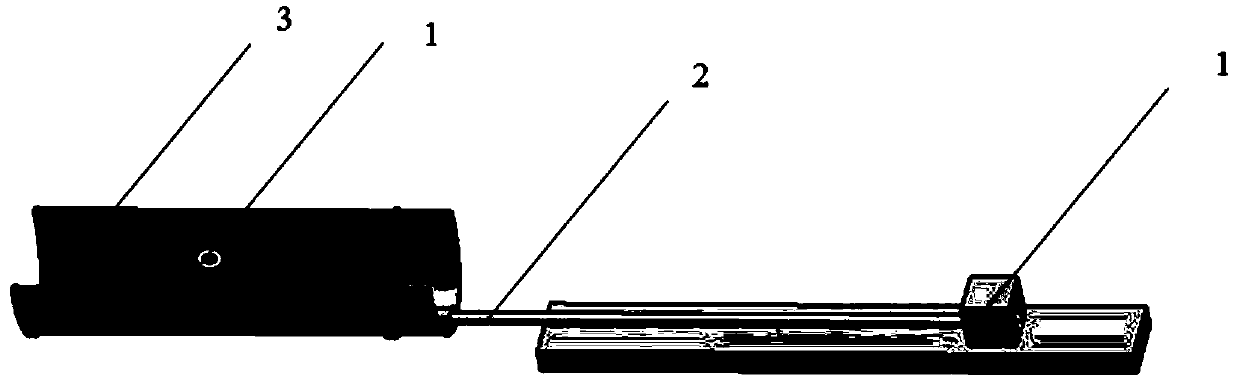

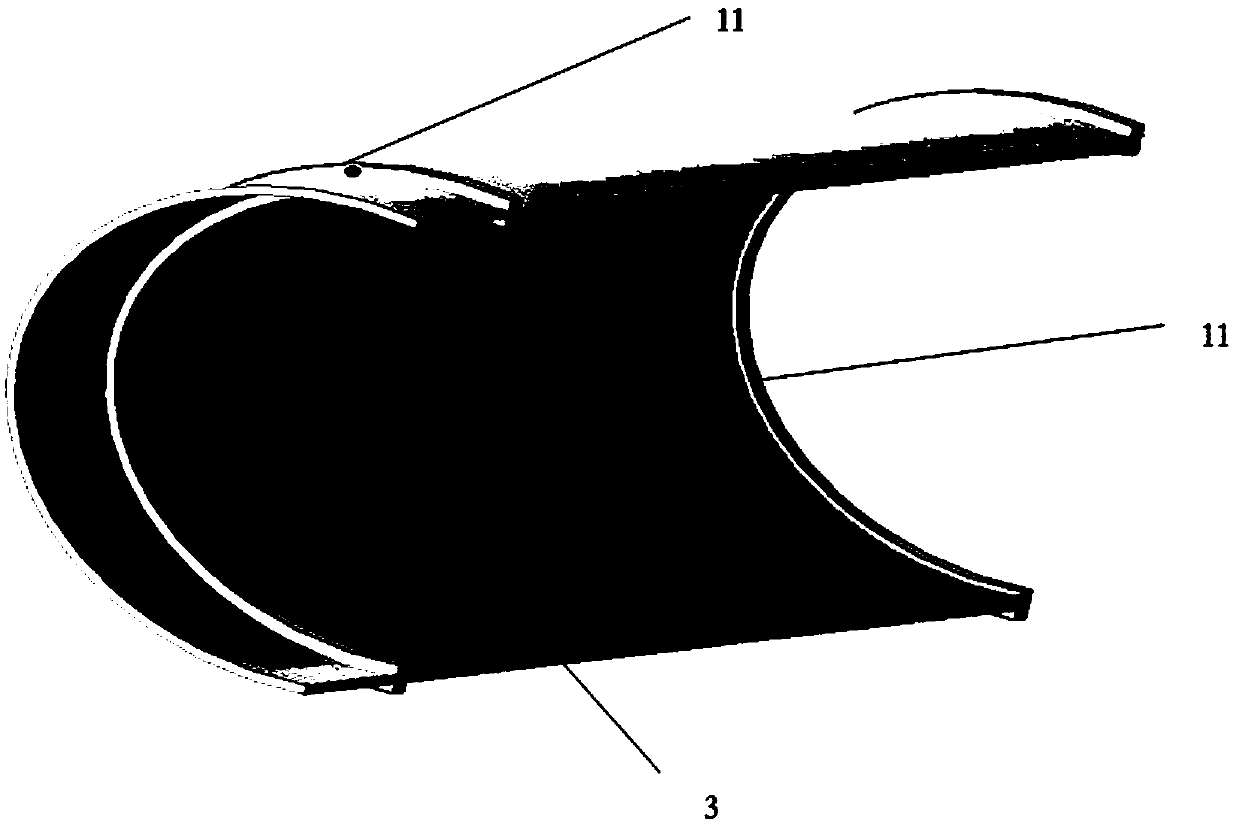

[0025] see figure 1 As shown, the present invention discloses a protective system for anti-icing and deicing experiments in an icing wind tunnel, including an air duct 4 , a protective cover 3 , an electric heating unit, and an air slide 1 located outside the air duct 4 . The air duct 4 is the experimental space for the aircraft wing icing experiment, and the simulated wing 5 to be tested is placed in the air duct 4 in advance, and the air in the air duct carries supercooled water droplets to impact. However, before the expected supercooled water droplet state is formed, it will take a period of time for the subcooled water droplets that do not reach the standard to be ejected from the air duct until the supercooled water droplet standard is reached, and the supercooled water droplets that do not reach the standard cannot contact the simulated wing 5 . At this time, the protective cover 3 needs to be used to protect the simulated wing 5 . Such as figure 1 As shown, the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com