Limiting device for tempered glass transferring

A technology of limiting device and tempered glass, which is applied to conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of glass damage, horizontal and vertical bumps, inconvenience in winding ropes, etc., and achieves the effect of improving safety and flexible design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

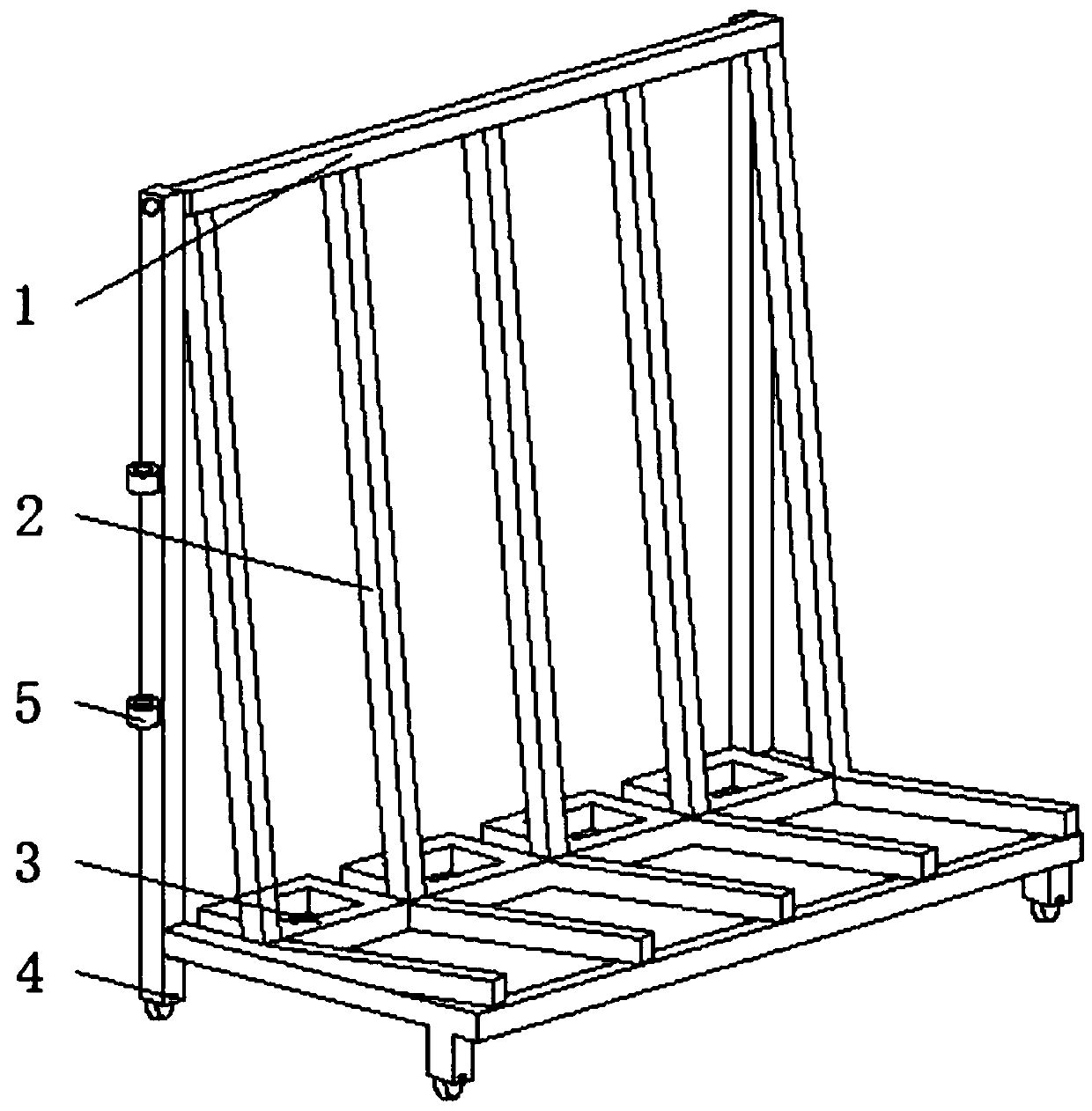

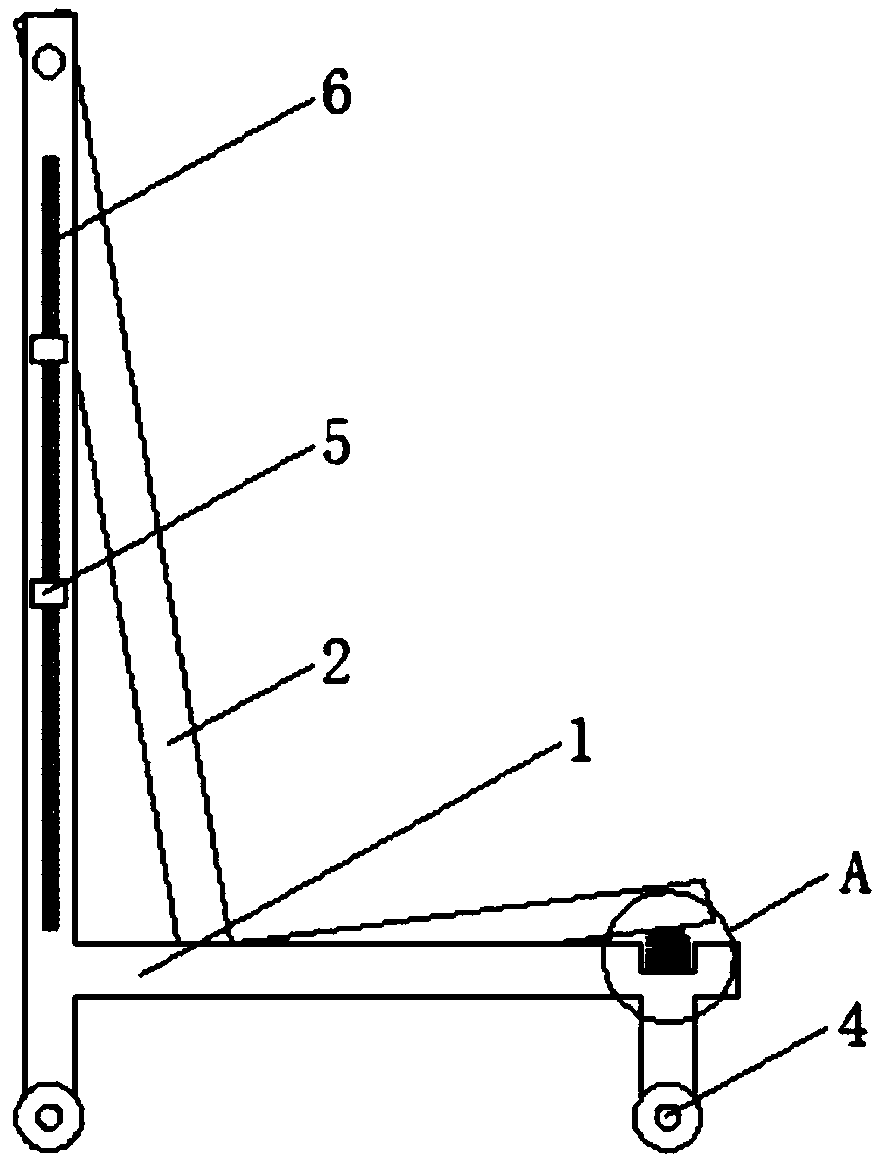

[0028] Such as Figure 1-5 As shown, a limiting device for tempered glass transfer includes a transfer frame 1, and is characterized in that: two of the transfer frame 1 are provided with a first chute 6, and a buckle 5 is installed in the first chute 6, The top of the transfer frame 1 is equipped with a number of L-shaped brackets 2 through the rotating shaft, and the right-angled sides of the L-shaped brackets 2 are connected by welding a number of bottom plates 3, and the angle between the L-shaped bracket 2 and the transfer frame 1 is 15-30° A second chute 7 is provided in the right-angled frame at the bottom of the L-shaped bracket 2, and a stopper 8 is movable embedded in the second chute 7, and an elastic member 14 is installed at the contact position of the right-angled frame with the transfer frame 1; The ring 5 is a hollow cylinder, and the embedded block welded at one end of the clasp 5 slides freely in the first sliding groove 6 .

[0029] The buckle 5 is provided...

Embodiment 2

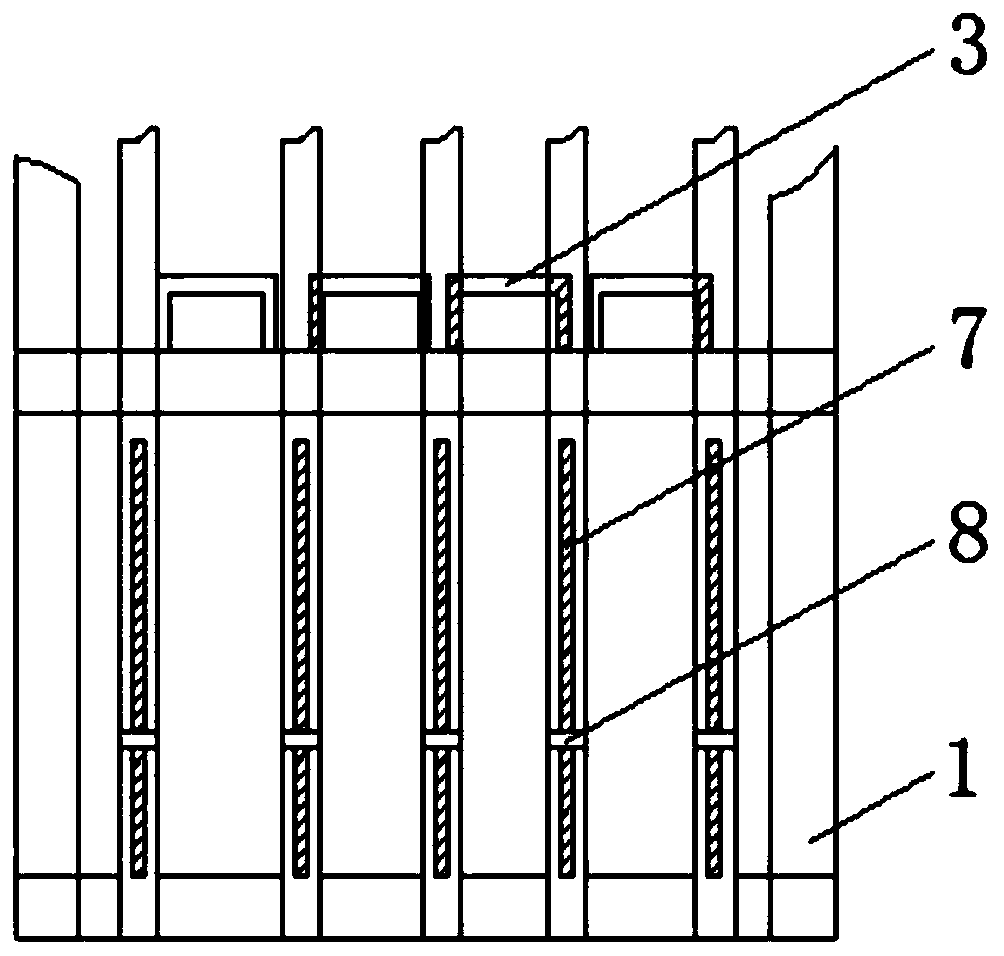

[0031] Such as Figure 1-5 As mentioned above, a slide bar 11 is installed through the second chute 7, and the surface of the slide bar 11 is fitted with a slide block 10. The top of the top is fixedly installed with a stopper 8 by screws, and the cross section of the stopper 8 is a right triangle.

[0032] The stopper 8 and the slider 10 are set to longitudinally limit the toughened glass placed on the L-shaped bracket. The contact surface between the stopper 8 and the toughened glass is bonded with a sponge pad by superglue for preliminary shock absorption and protection. A compression spring 12 is provided to clamp the tempered glass while limiting the position. The more tempered glass there is on the L-shaped bracket 2, the more the compression spring 12 will compress, so the position-limiting effect will be better. Within the elastic limit, it can More tempered glass is placed, and the design is flexible.

Embodiment 3

[0034] Such as Figure 1-5 As shown, the elastic member 14 is embedded in the L-shaped bracket 2 and corresponds to each L-shaped bracket 2 one by one. The bottom side of one end of the L-shaped bracket 2 is fixed with a washer 13 by a screw, and the washer 13 is closely attached to the elastic member 14. combine;

[0035] Elastic piece 14 is set, if run into road section unevenness in transfer process, cause bump up and down, elastic piece 14 has played buffering effect, avoids that toughened glass vibrates up and down on L-shaped bracket 2 and causes collision, has improved the security of transportation.

[0036] The right-angle inner edge of the L-shaped support 2 is fixedly connected with a rubber pad 9 by screws, and the opening provided by the rubber pad 9 at the top position of the second chute 7 communicates with the second chute 7, and the positions of the rubber pad 9 are all in line with the second chute 7. The tempered glass is in contact, and the transfer increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com