Enhanced bioelectrochemical hydrogen production method and bioelectrochemical hydrogen production system

A bioelectrochemical and hydrogen system technology, which is applied in the field of enhanced bioelectrochemical hydrogen production methods and bioelectrochemical hydrogen production systems, can solve problems such as increasing the internal resistance of the system, increasing energy consumption, and reducing Coulomb efficiency, and achieves enhanced Hydrogen production performance and methanation inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

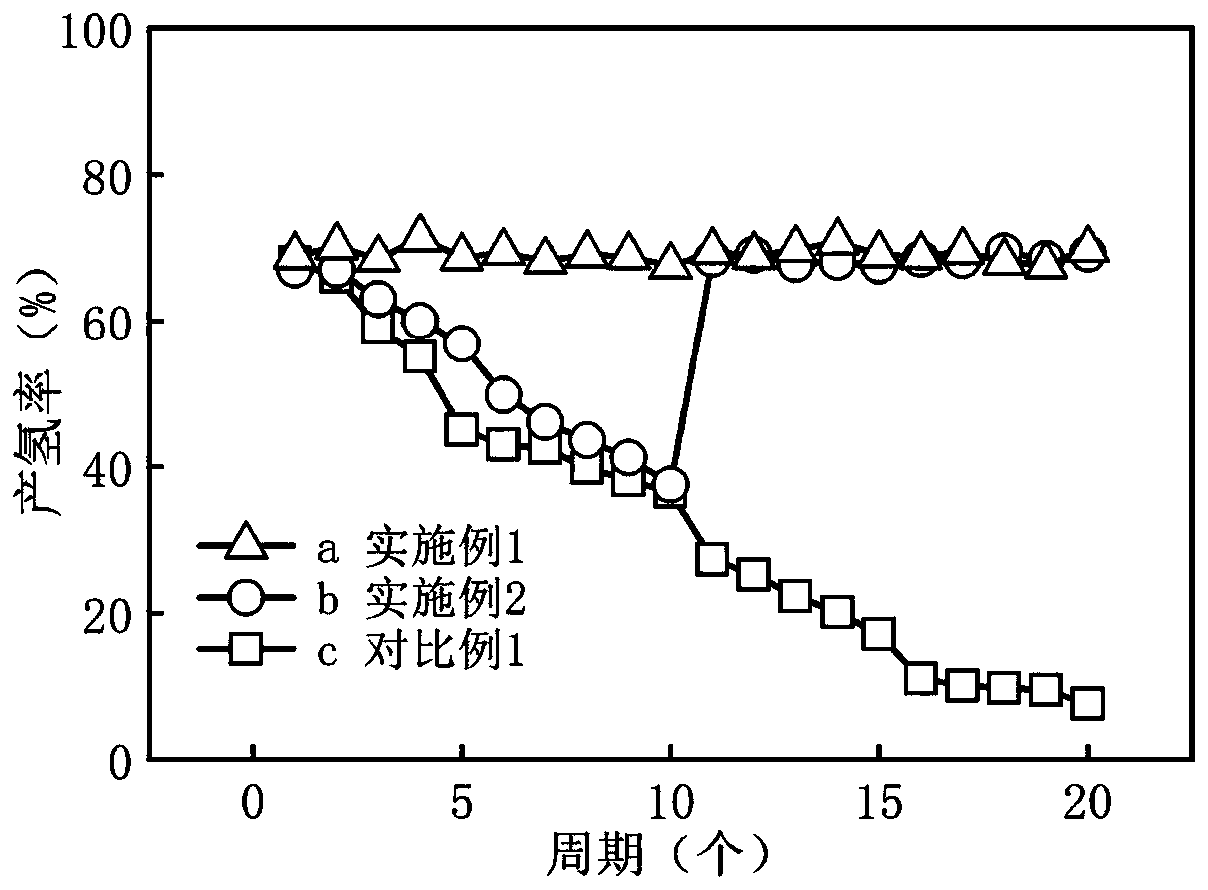

Embodiment 1

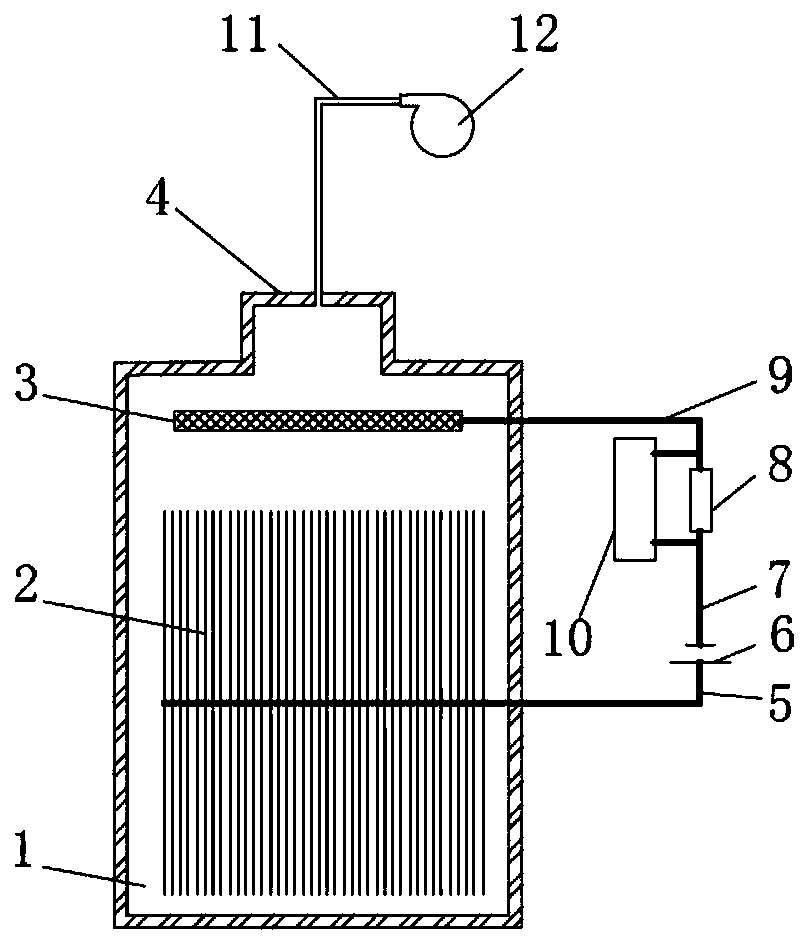

[0071] The enhanced bioelectrochemical hydrogen production method of this embodiment specifically includes the following steps:

[0072] (1) Cultivate anode electrogenic bacteria in microbial fuel cell (MFC) mode

[0073] Mix the medium (composed of sodium acetate, phosphate buffer, vitamins and trace elements) with the inoculum (excess sludge, sludge from the secondary sedimentation tank of the sewage treatment plant) at a volume ratio of 1:1, and pass it into High-purity nitrogen was blown off for 10 minutes to remove the dissolved oxygen, and then fed into the microbial fuel cell together; a 1000Ω resistor was connected to the closed circuit system and operated in a static batch mode. When the voltage across the resistor exceeded 0.1V, There is no need to use the inoculum, and the culture medium is directly added to the microbial fuel cell, and repeated for at least three cycles, until the microbial fuel cell stably outputs the maximum voltage, at which point it is consider...

Embodiment 2

[0078] The enhanced bioelectrochemical hydrogen production method of this embodiment specifically includes the following steps:

[0079] (1) Cultivate anode electrogenic bacteria in microbial fuel cell (MFC) mode

[0080] Mix the medium (composed of sodium acetate, phosphate buffer, vitamins and trace elements) with the inoculum (excess sludge, sludge from the secondary sedimentation tank of the sewage treatment plant) at a volume ratio of 1:1, and pass it into High-purity nitrogen was blown off for 10 minutes to remove the dissolved oxygen, and then fed into the microbial fuel cell together; a 1000Ω resistor was connected to the closed circuit system and operated in a static batch mode. When the voltage across the resistor exceeded 0.1V, There is no need to use the inoculum, and the culture medium is directly added to the microbial fuel cell, and repeated for at least three cycles, until the microbial fuel cell stably outputs the maximum voltage, at which point it is consider...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap