Steel bar planting-free construction method for secondary structure steel bar

A technology of secondary structure and construction method, which is applied in the direction of building structure, formwork/formwork/working frame, and on-site preparation of building components. Inconvenience, large manpower and material resources, etc., to achieve the effect of simple setting of steel bar reservation, reduction of labor for planting bars, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

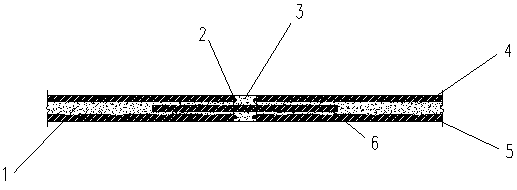

[0023] see now figure 1 , figure 1 A schematic diagram is reserved for the reinforcing bars of the 3-meter-long bottom beam of the embodiment of the present invention.

[0024] a. Formwork support. In the bottom beam 1 with a length of 3 meters, the wooden square 4 at the bottom of the first beam and the wooden square 5 at the bottom of the second beam are respectively 1415 mm long and 50 mm wide, and they are arranged in parallel up and down, and a formwork disconnection position 3 is provided in the middle. In the template disconnection position 3, reserve steel bars 2 are respectively set in the positions of the first beam bottom wooden square 4 and the second beam bottom wooden square 5. Insert a wooden square 6 with a width of 50 mm between the wooden square 4 at the bottom of the first beam and the wooden square 5 at the bottom of the second beam, and the wooden square 6 is parallel to the wooden square 4 at the bottom of the first beam.

[0025] b. Drill holes accord...

Embodiment 2

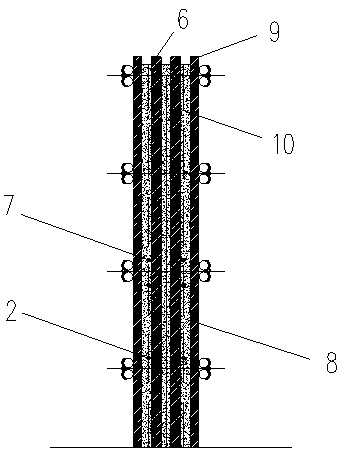

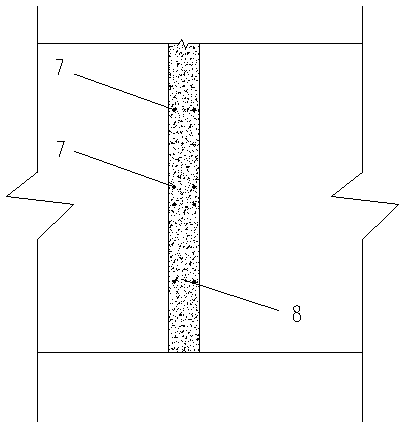

[0032] figure 2 A schematic diagram is reserved for the tie bars at the head plate of the panel wall according to the embodiment of the present invention. For concrete walls with a height greater than 2000mm, square steel 9 templates are supported on both sides of the concrete wall, and steel pipe clamps are used to tighten every 500mm in the height of the concrete wall. Two parallel wooden squares 6 with a certain distance are set between the steel 9 formworks. Set the reserved steel bar 2 at 500mm upward from the foot of the concrete wall, and then set the reserved steel bar 7 for the waist beam at 1000mm upward to complete the supporting formwork and reserved steel bar. image 3 It is the plan view of the reinforcement bars reserved in the middle wall of the formwork according to the embodiment of the present invention, and the distance between the reinforcement bars 7 reserved for two adjacent waist beams is 500mm.

[0033] The remaining steps of this embodiment are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com