Shaving board with auxiliary heat supply supporting structure

A technology for supporting structure and auxiliary heating, applied in the field of particleboard, can solve the problems of poor structural integrity of the particleboard, and achieve the effects of facilitating installation, fixing and positioning, reducing installation difficulty and improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

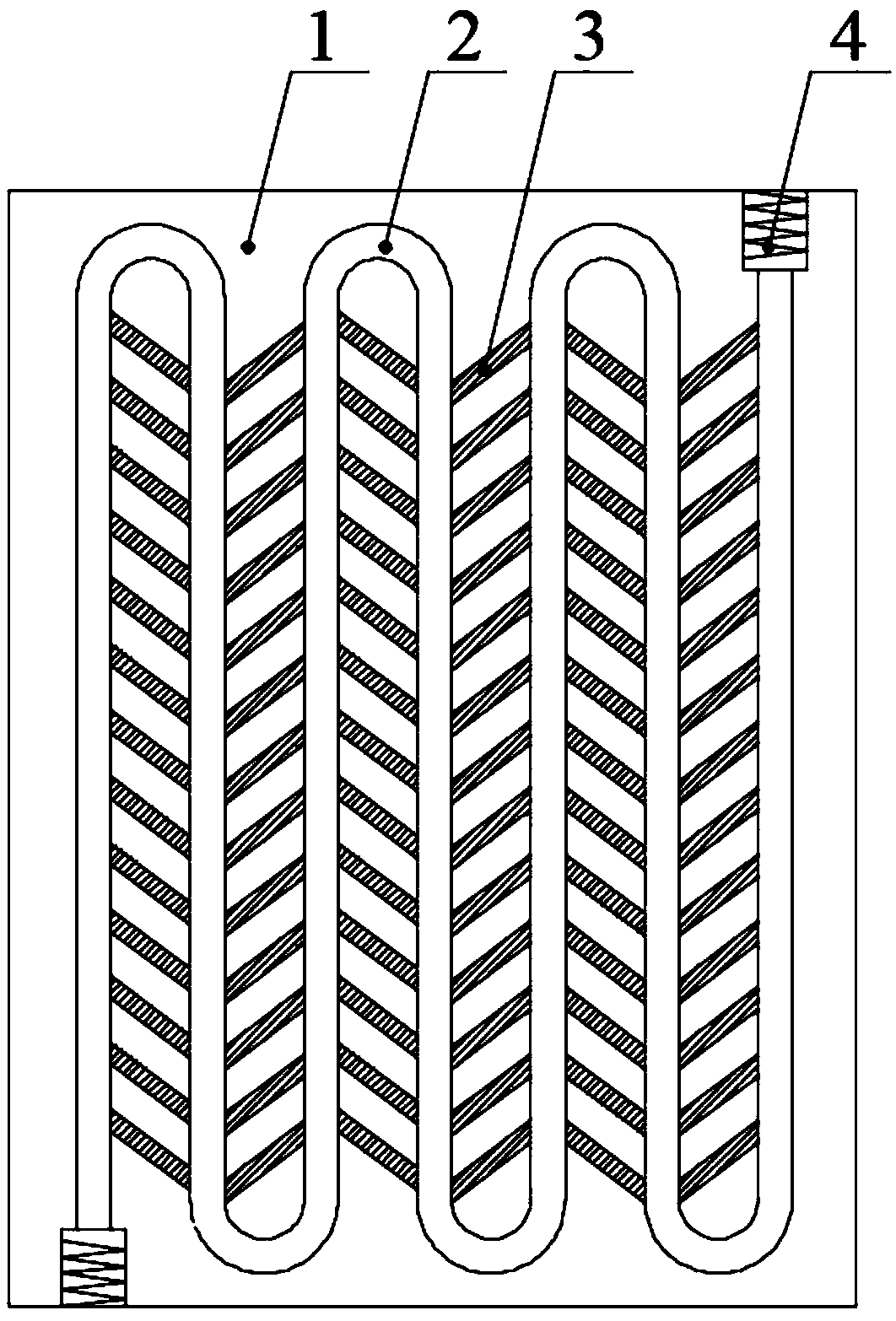

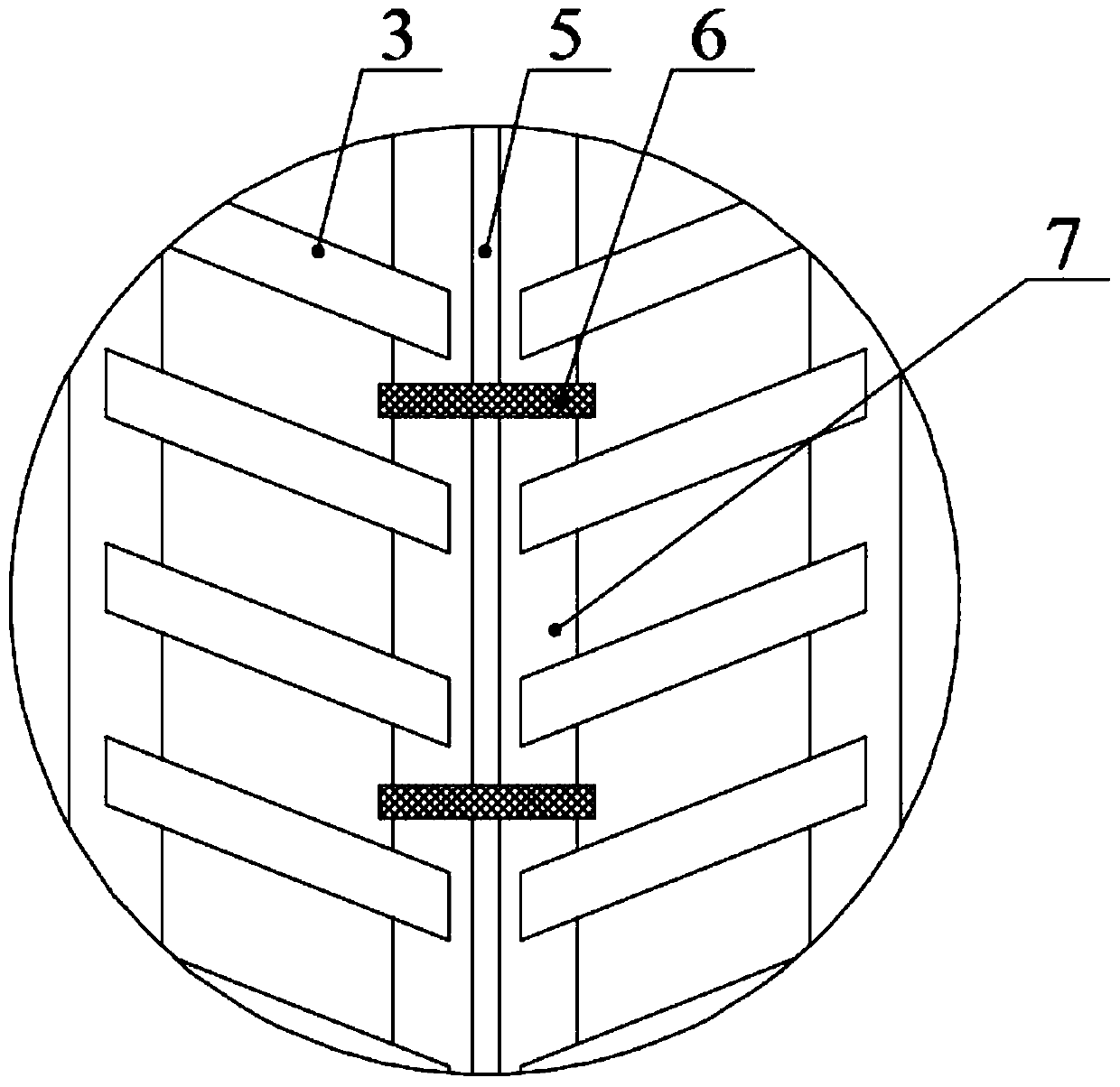

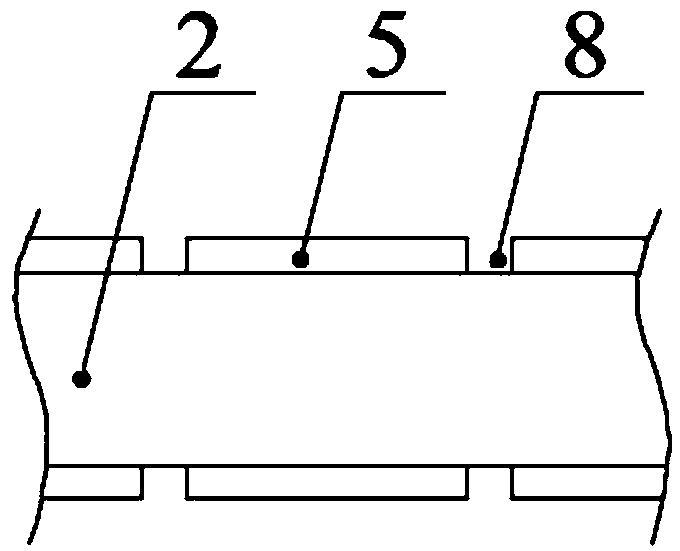

[0018] A particleboard with an auxiliary heating support structure, the interior of the particleboard 1 is fixedly embedded with a heating support frame, and the heating support frame includes a connected row pipe 2 and a heat conduction support piece 3; the two ends of the row pipe are sealed and fixed with threads Socket pipe 4, and several heat-conducting support sheets are fixed between every two adjacent pipelines in the row pipe; the end of the threaded socket pipe is flush with the side wall of the particleboard, and the inner wall of the threaded socket pipe There are connecting threads on it.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com