Rotating blade underwater dynamic deformation binocular measurement system of composite material propeller model

A technology of composite materials and rotating blades, which is applied in the field of binocular measurement system for underwater dynamic deformation of rotating blades of composite propeller models. Real-time feature relations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

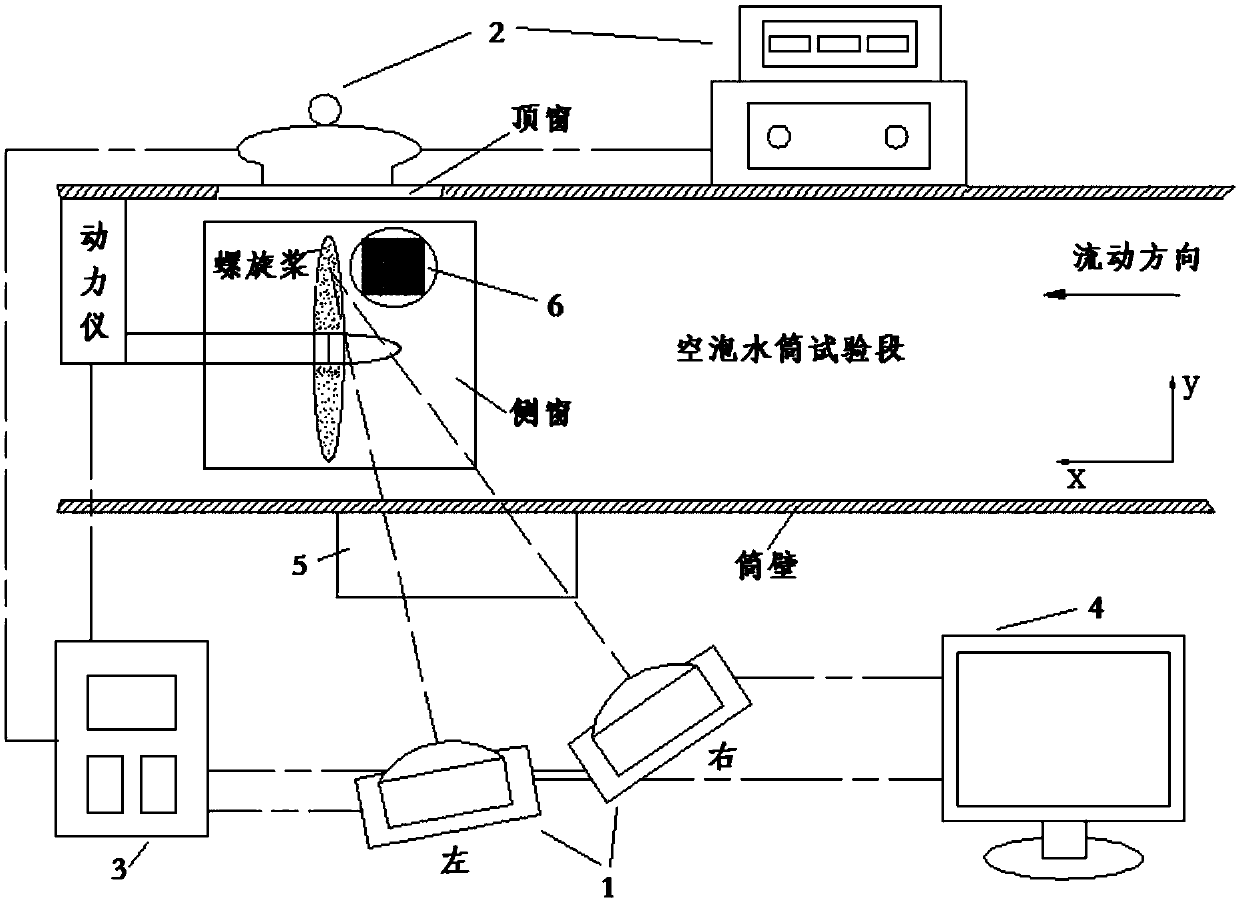

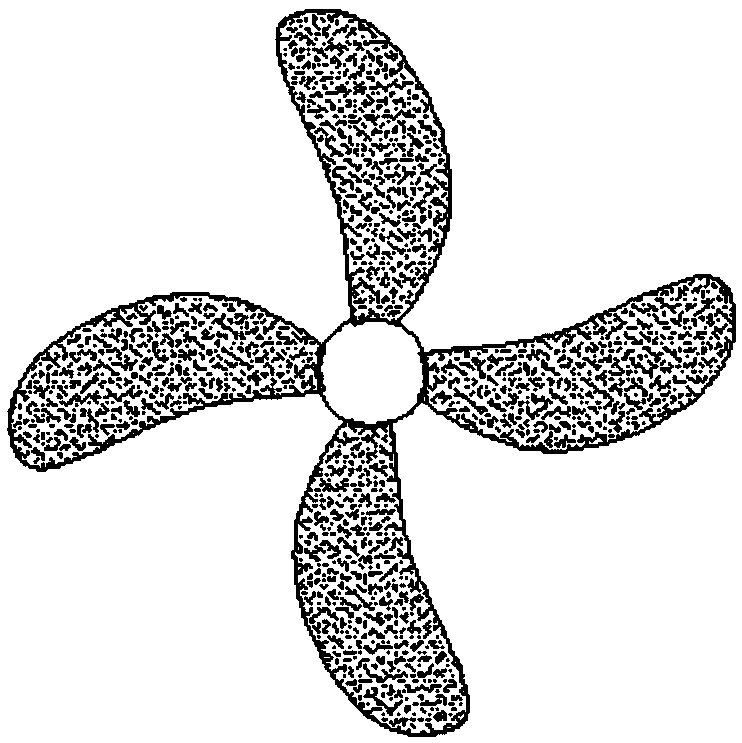

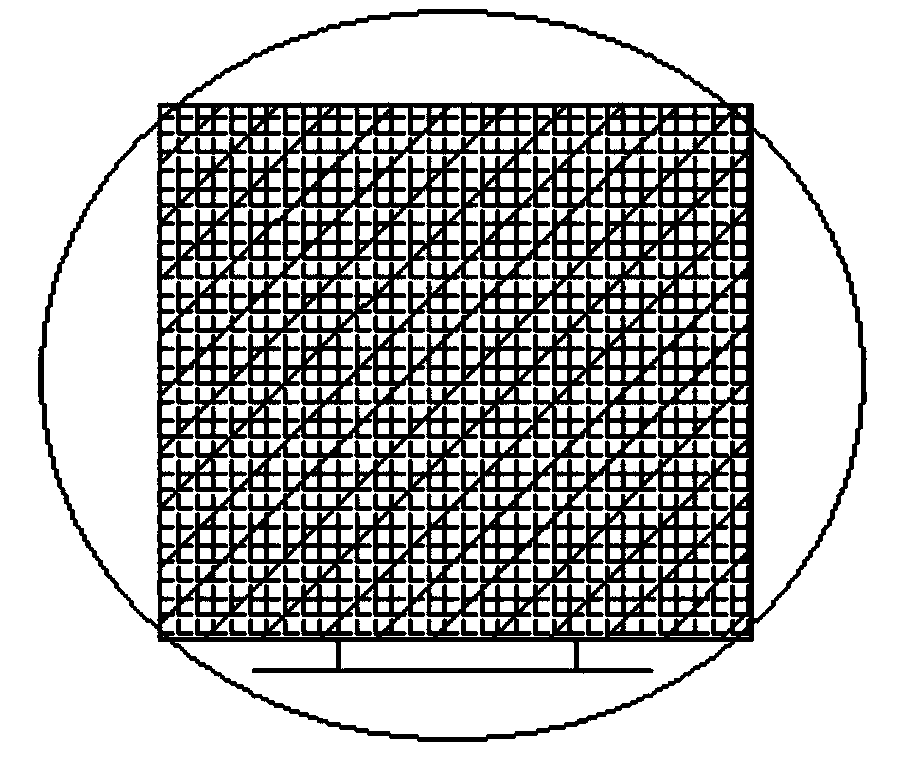

[0033] figure 1 It is a schematic diagram of a composite material propeller model rotating blade underwater dynamic deformation binocular measurement system provided by an embodiment of the present invention, as shown in figure 1 As shown, the measurement system may include: two cameras 1, white light strobe light source equipment 2, synchronizer 3, speckle image acquisition processing and cross-correlation analysis software system 4, optical auxiliary equipment 5, target 6, and dynamic instrument.

[0034] The two cameras are arranged next to the observation window on the side of the cavitation water cylinder test section at about 1 minute, so that the object to be tested can be imaged in the image plane of the two cameras 1 at the same time, and the angle between the optical axes of the two cameras 1 is between 12° and 15°. ° between.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com