Ground test verification system of subsonic speed cabin level thermal control design

A ground test and verification system technology, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices, can solve the problems of limited engine working life, high cost, and inability to simulate and verify the aerodynamic conditions of the outer wall of the cabin. High heaven and earth consistency, simple preparation process, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

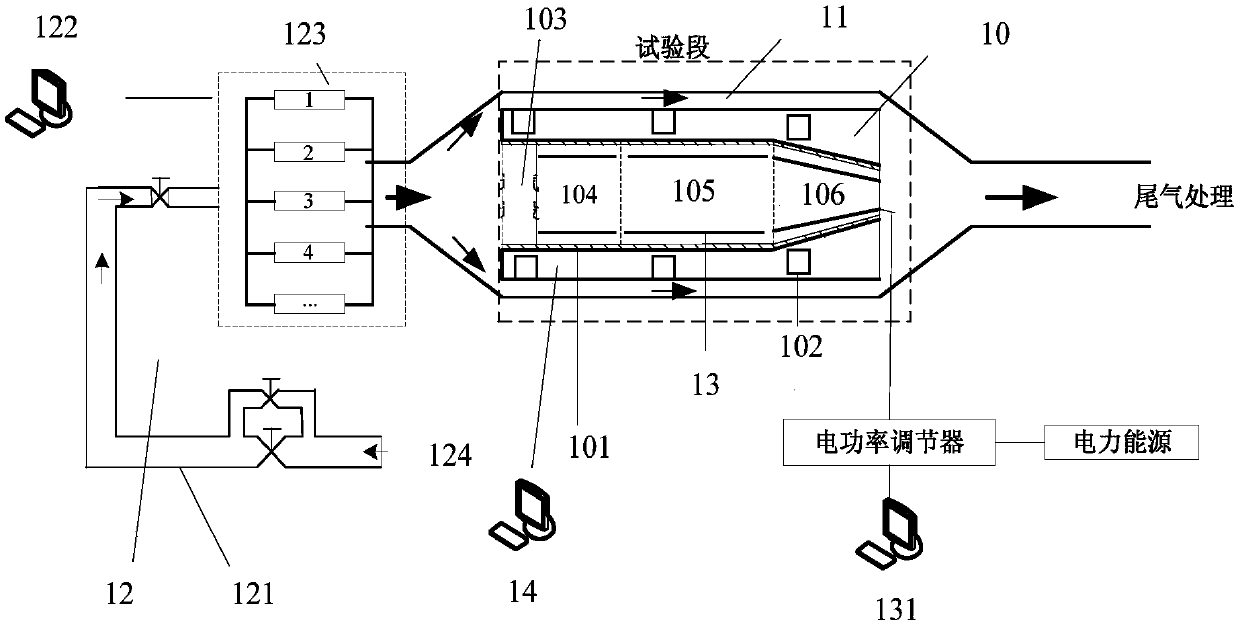

[0030] see figure 1 , this embodiment provides a ground test verification system for subsonic cabin level thermal control design, which includes:

[0031] A test chamber 10 placed inside an external flow field channel 11, wherein:

[0032] The inside of the test cabin body 10 is provided with a sleeve structure 101, and the sleeve structure 101 is successively divided into an air inlet section 103, an oil tank section 104, an engine body section 105 and an exhaust pipe section 106, wherein the air inlet Section 103 and lubricating oil tank section 104 are blocked, adopt heating system 13 to respectively heat in described lubricating oil tank section 104, engine body section 105 and tail nozzle pipe section 106, realize simulation engine body, lubricating oil tank and tail nozzle pipe three the heat source of each part;

[0033] Test equipment 102 is placed in other areas of the test cabin 10 except the sleeve structure 101;

[0034] The air electric heating system 12 placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com