Method for preparing graphene nanonet by using patterned substrate imprinting

A technology for patterning substrates and substrates, applied in nanotechnology, photoengraving process of patterned surface, process for producing decorative surface effects, etc., can solve problems affecting electrical and mechanical properties, etc., and achieve low-defect GNM The preparation, preparation process is simple, and the operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

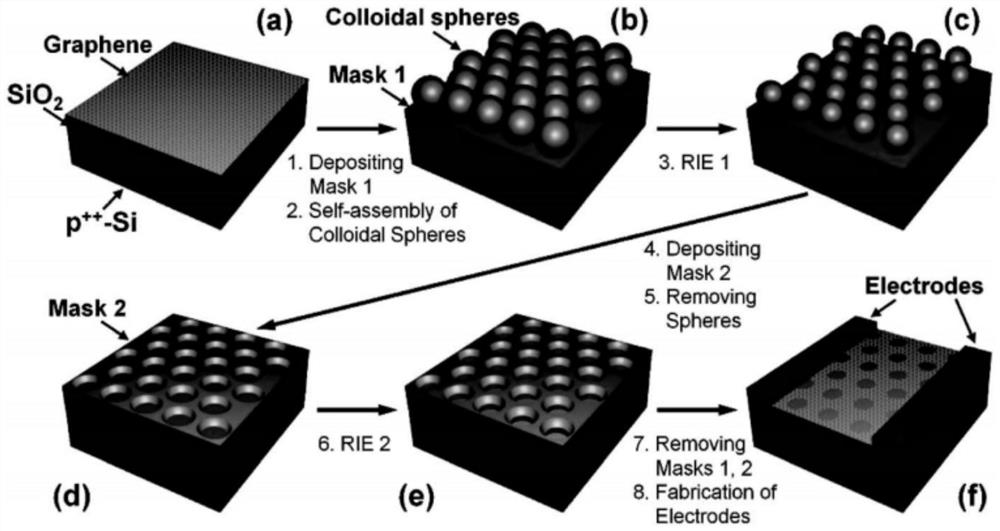

[0076] A method for preparing GNM by embossing a patterned substrate refers to: using a patterned substrate with a higher hardness to emboss a substrate / Gr with a lower hardness, and making the raised pattern of the patterned substrate pass through Through Gr, the preparation of fast, large-area, uniform, low-cost, high-porosity, and low-defect GNMs is realized.

Embodiment 2

[0078] According to a method for preparing GNM by imprinting a patterned substrate according to Embodiment 1, the difference is that:

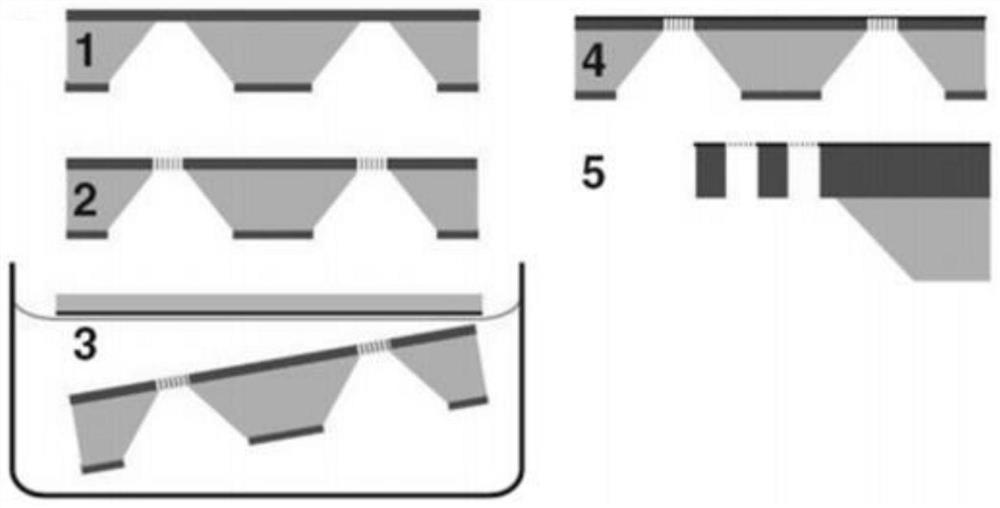

[0079] The method of preparing GNM by imprinting on a patterned substrate is now taking the preparation of GNM by embossing Cu / Gr on a patterned sapphire substrate as an example. The size of the patterned sapphire substrate and Cu / Gr (Cu-based Gr) used are about It is 5mm×5mm. Such as Figure 5 shown, including the following steps:

[0080] (1) Preparation: Prepare the substrate / Gr; Cu / Gr is obtained by directly growing Gr on the Cu substrate by metal organic chemical vapor deposition (MOCVD). The morphology of Cu / Gr is shown in Fig. 7(a), which is single-layer single-crystal (not fully covered).

[0081] (2) Cleaning: Select sapphire with a mode hardness (hardness of 9) greater than Cu as the patterned substrate, and its appearance is as follows Image 6 As shown, the raised pattern is a hemispherical structure arranged periodically, and ...

Embodiment 3

[0090] According to a method for preparing GNM by imprinting a patterned substrate according to Embodiment 2, the difference is that:

[0091] Step (1) refers to: using PMMA to wet transfer Gr to the substrate to prepare the substrate / Gr.

[0092] In step (4), the embossing method includes punching and rolling.

[0093] The number of layers of Gr is single layer or multilayer.

[0094] Periodic raised patterns are prepared by wet etching or dry etching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com