Vehicle-mounted head-up displayer cover plate assembly and testing device and testing method of assembly

A technology for head-up display and testing equipment, which is used in vehicle testing, optical instrument testing, and machine/structural component testing. Cover shaking and other problems to achieve accurate and efficient testing, reliable performance, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

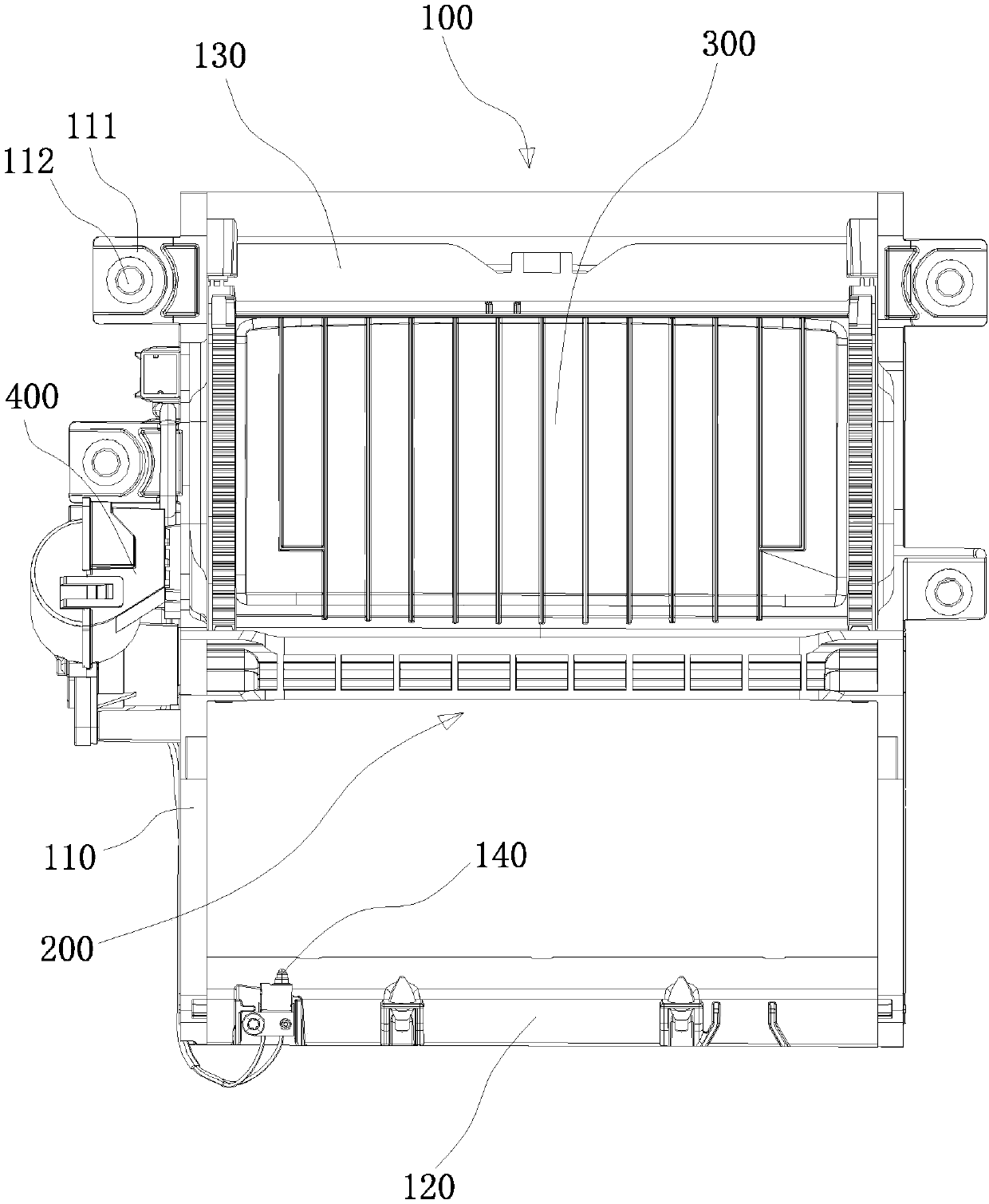

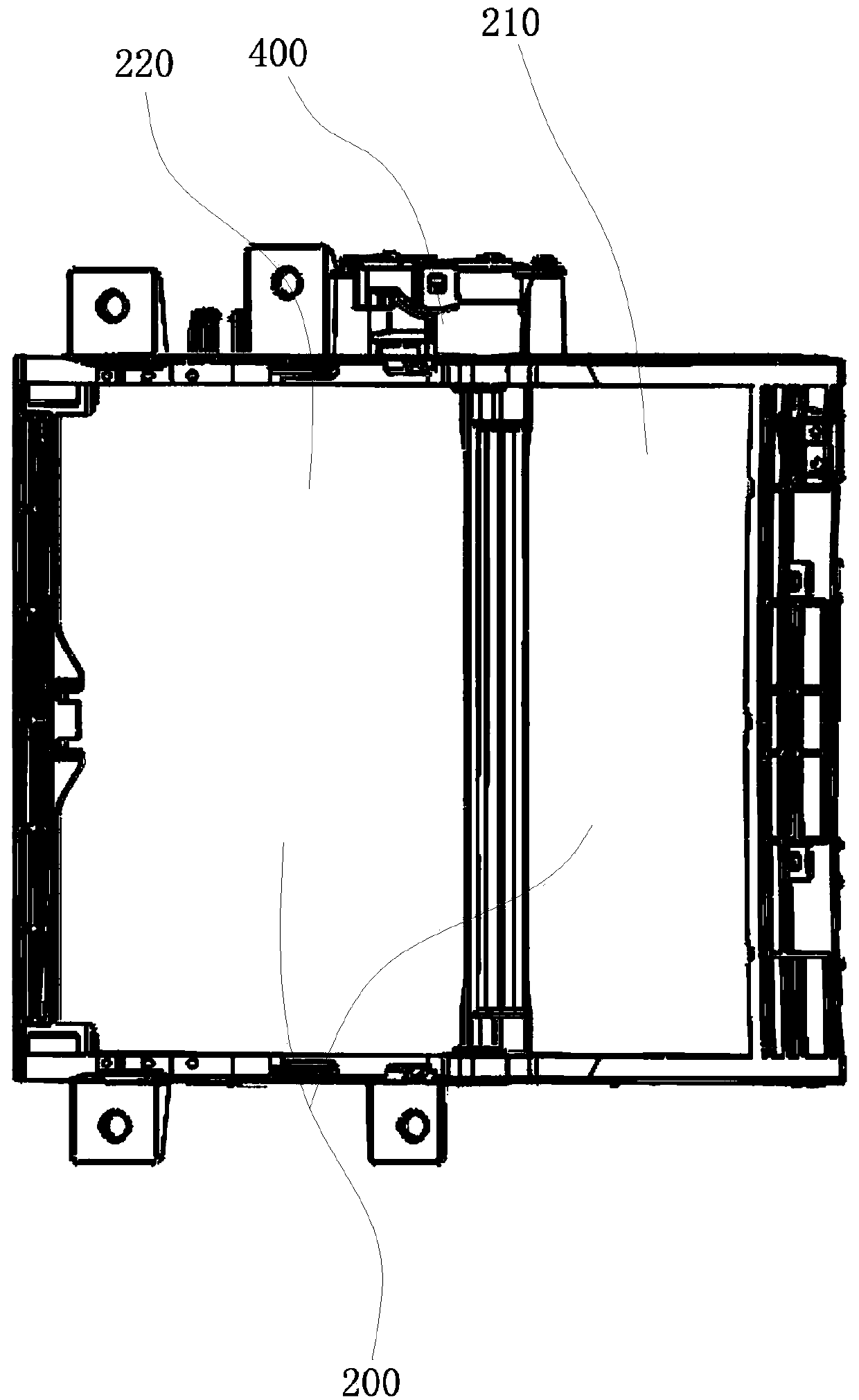

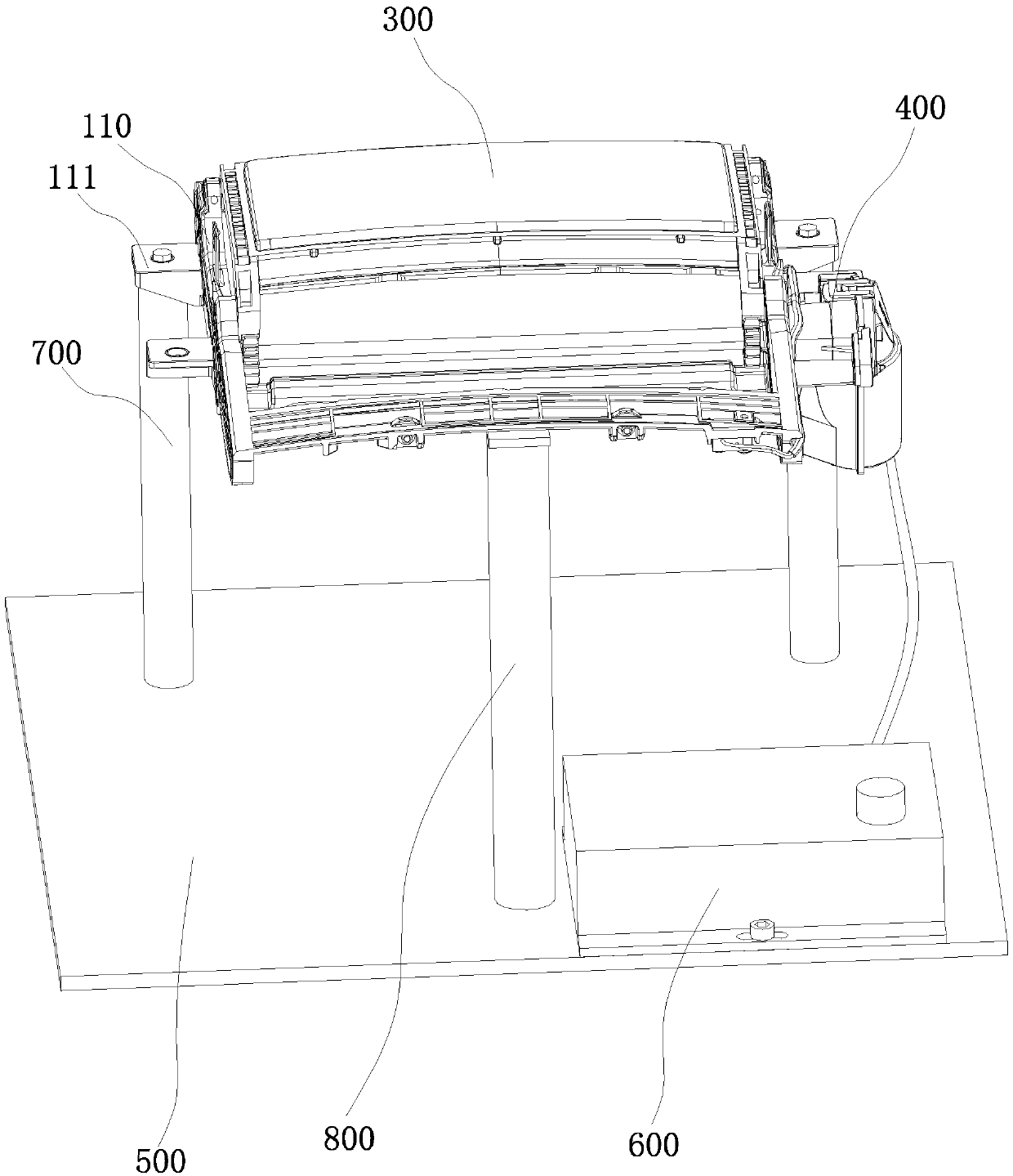

[0032] Such as figure 1 , figure 2 As shown, a vehicle-mounted head-up display cover assembly includes: a cover frame 100, a sliding cover 300 and a drive unit 400, the sliding cover is arranged on the cover frame, and the drive unit 400 is connected to the cover frame. The sliding cover 300 is connected in linkage and drives the sliding cover 300 to slide on the cover frame 100 .

[0033] The vehicle-mounted head-up display uses the principle of optical reflection to project important vehicle driving data onto the front windshield for display. The height of the data display position is the same as the height of the driver's eyes. Its purpose is to assist the driver to drive the vehicle and improve driving safety. The vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com