Magnetic shoe magnetizing device

A technology of magnetizing device and magnetic tile, applied in electromechanical devices, magnetic objects, electrical components, etc., can solve the problems of low precision, low processing efficiency, and poor flow rigidity of tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

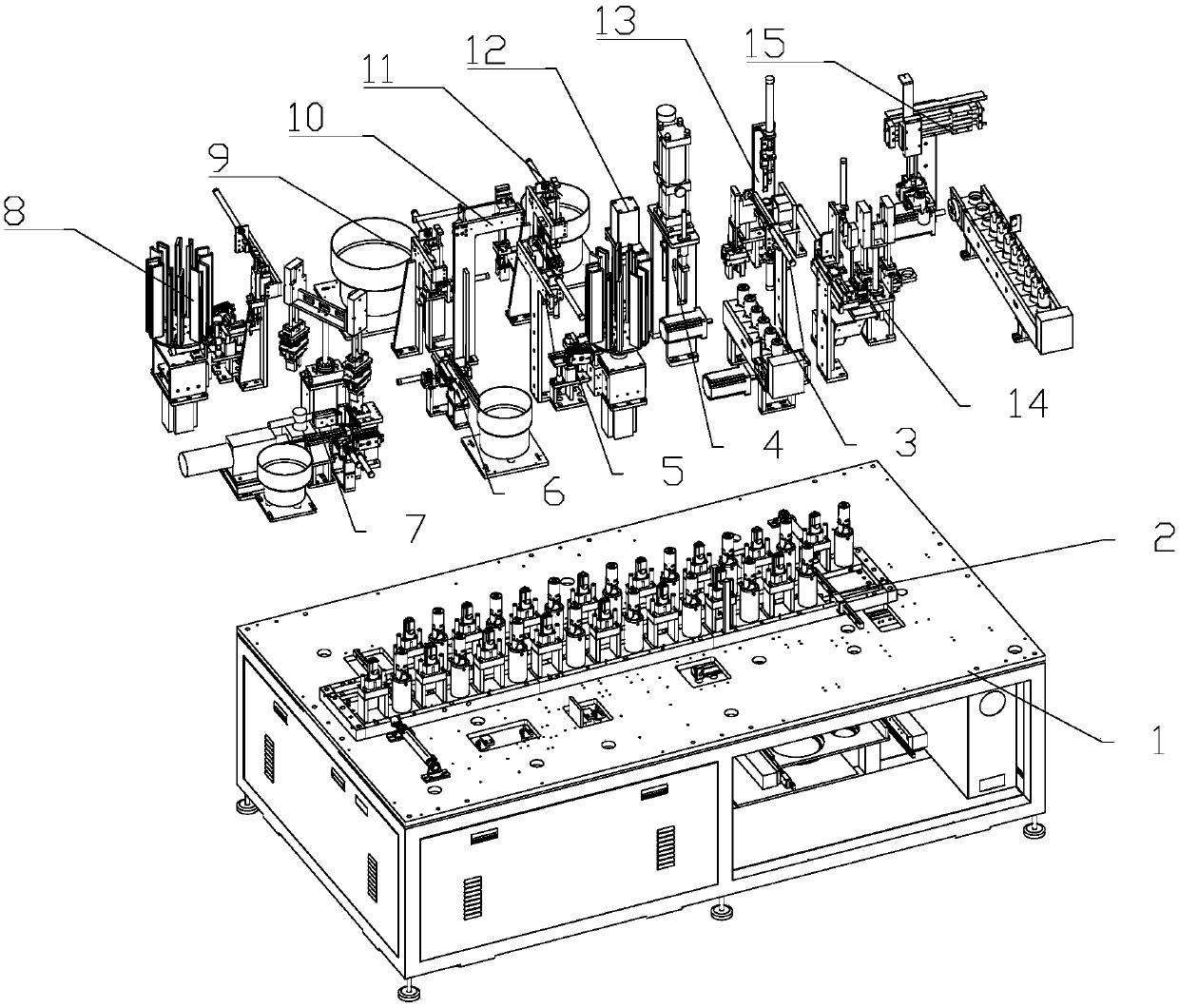

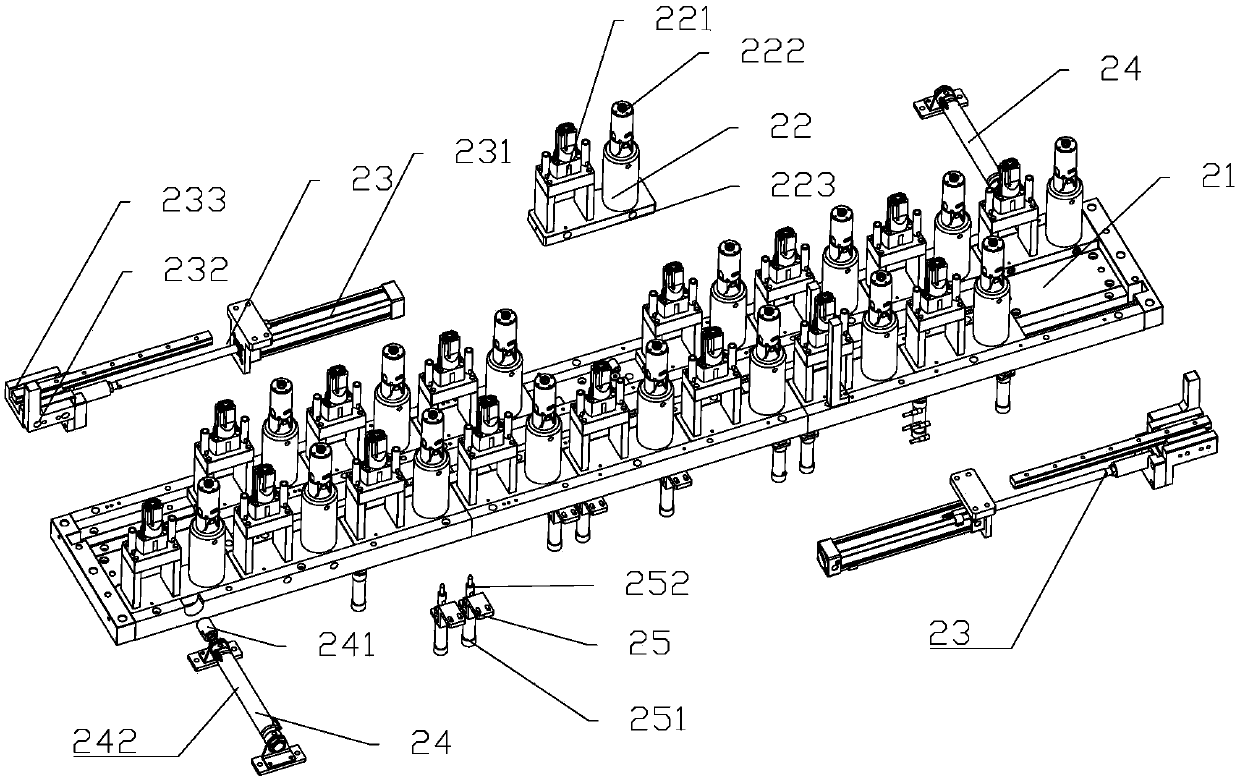

[0036] Such as figure 1As shown, the described automatic assembly equipment for micro DC motors is characterized in that it includes a frame (1), a tooling circulation device (2) installed on the frame (1), and a casing feeding device (3) , Shell riveting device (4), first magnetic tile feeding device (5), shrapnel feeding device (6), ground wire welding device (7), second magnetic tile feeding device (8), bearing pressure Spring feeding device (9), casing transfer device (10), bearing feeding device (11), magnetic tile pressing device (12), magnetic tile magnetizing device (13), glue coating device (14) and The finished product unloading device (15); the tooling circulation device (2) is installed in the center of the casing feeding device (3), and is used for placing and transporting the casing to be assembled, and a mobile unit of the tooling circulation device (2) has Two different fixtures, one mobile unit has only one casing; the casing feeding device (3) is located nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com