Pressurization type steam-aging device

A technology of aging device and pressurized steam, which is applied in the field of lime calcination to reduce the frequency of equipment maintenance and improve the aging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

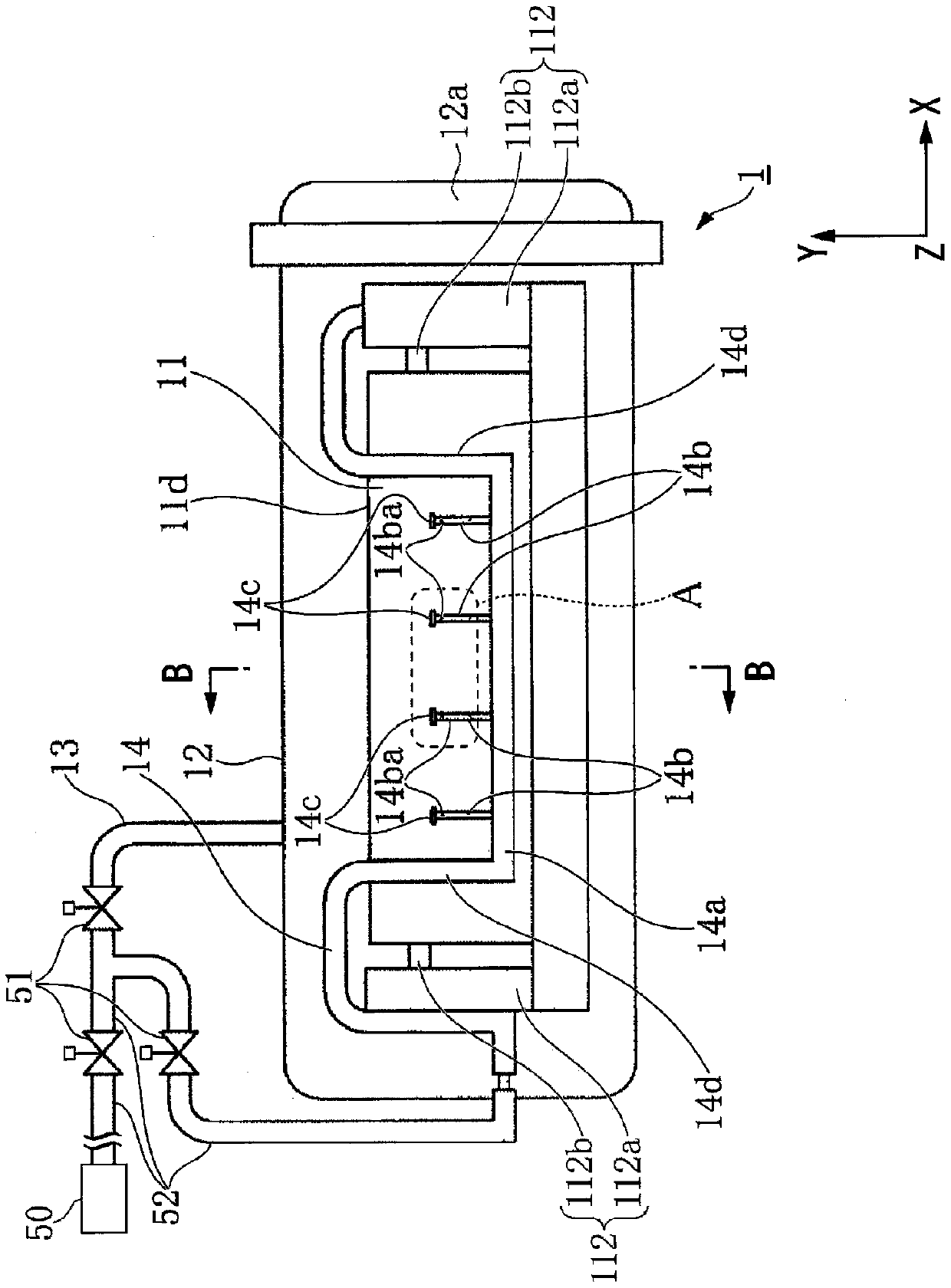

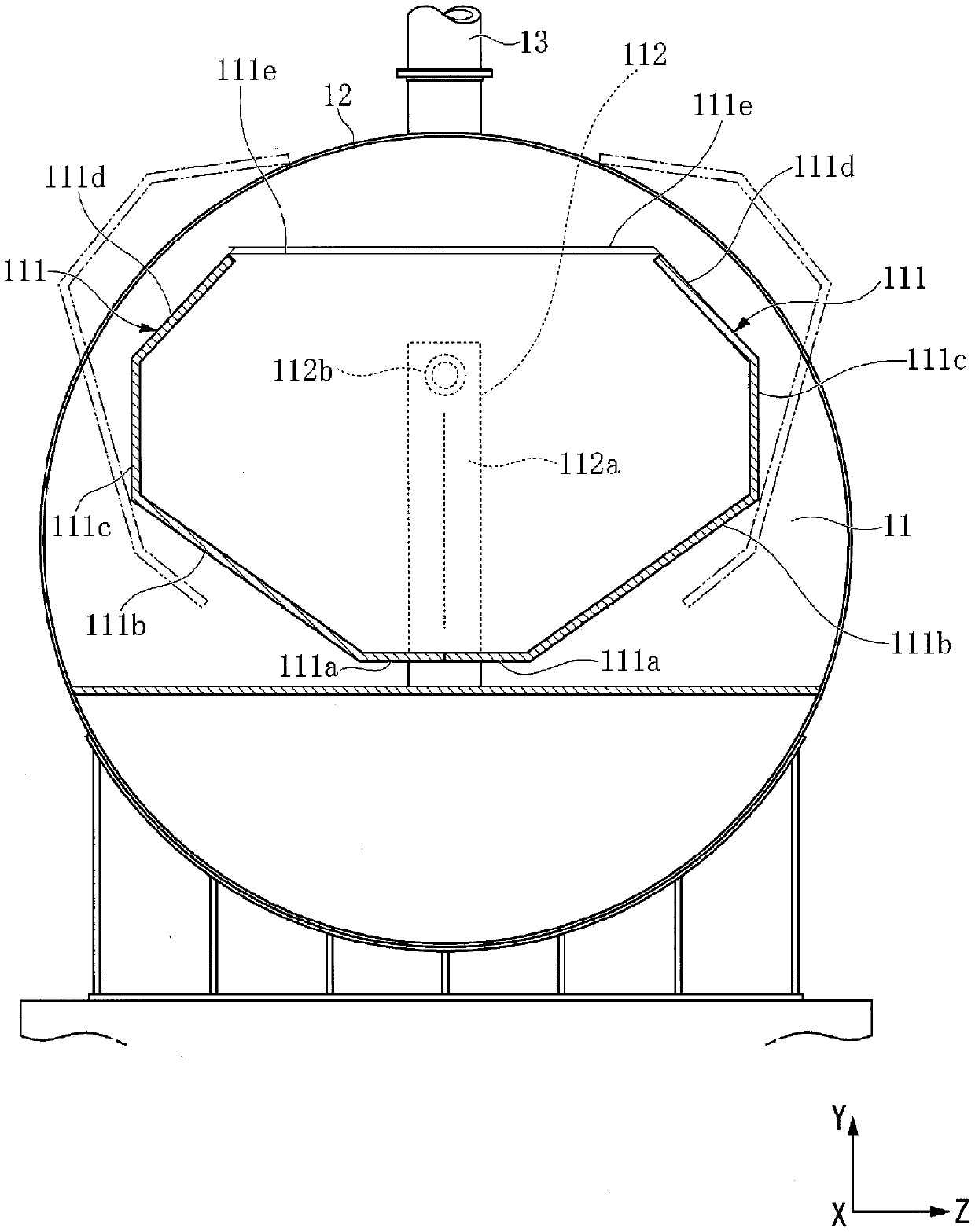

Embodiment Construction

[0065] The present inventors conducted intensive studies on suppressing the frequency of equipment maintenance and improving aging efficiency in a pressurized steam aging apparatus. As a result, the following findings were obtained.

[0066] Such as Figure 10A , Figure 10B As in the prior art shown, when the holes 205a for ejecting steam are formed in the pipes 205 arranged in the longitudinal direction, the steelmaking slag in the vicinity of the holes 205a exists at a high filling degree. In this case, steam is prevented from being ejected from the hole 205a. In addition, there is the attendant risk of clogging of the hole 205a. Therefore, if the steam hole is formed on the side of the vertically standing branch pipe, the steelmaking slag dropped from above collides with the upper part of the pipe, and the filling degree of the steelmaking slag near the hole can be reduced. As a result, steam can be efficiently ejected from the holes, and clogging can be prevented.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com